When working with steel, selecting the right angle grinder disc types for steel is crucial for achieving precise and efficient cuts, grinding, and polishing. The variety of discs available can make choosing the right one challenging, but understanding their features and applications can help professionals and DIY enthusiasts make informed decisions.

One of the most common angle grinder disc types for steel is the grinding disc. This disc is primarily used for smoothing rough edges, deburring metal surfaces, and removing excess material. Made from high-quality abrasives, grinding discs ensure durability and efficiency in heavy-duty applications.

Another popular angle grinder disc types for steel is the flap disc. These discs feature overlapping abrasive flaps that provide a finer finish while still offering material removal capabilities. Flap discs are perfect for smoothing welds, cleaning metal surfaces, and preparing steel for painting or coating.

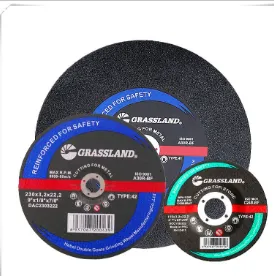

Cutting discs are essential angle grinder disc types for steel when it comes to slicing through metal quickly and efficiently. These thin discs are designed for precision cutting, reducing waste while providing clean and smooth edges. They are available in different thicknesses and materials to suit various cutting needs.

Wire brush discs are another useful angle grinder disc types for steel, commonly used for rust and paint removal. These discs feature wire bristles that effectively clean metal surfaces, making them ideal for restoration projects and surface preparation before welding.

Lastly, diamond discs are high-performance angle grinder disc types for steel used for precision cutting and shaping. While primarily used for cutting harder materials like stone and concrete, some diamond discs are specifically designed for metal applications, providing exceptional durability and precision.

Selecting the right angle grinder disc types for steel depends on the specific task at hand. Whether cutting, grinding, or polishing, using the appropriate disc ensures efficiency, safety, and the best possible results.

Metal Cutting Disc: Essential for Precision and Efficiency

A metal cutting disc is a vital tool in any metalworking environment, allowing professionals and DIY users to cut through steel, iron, and other metals with accuracy and ease. Choosing the right metal cutting disc ensures efficiency, durability, and safety in every cutting task.

The most common type of metal cutting disc is the standard abrasive disc. These discs are made from aluminum oxide or zirconia, offering a balance between affordability and performance. They are ideal for general-purpose metal cutting tasks and are widely used in workshops, construction sites, and fabrication industries.

For heavy-duty applications, reinforced metal cutting disc options are available. These discs are reinforced with fiberglass or other strengthening materials to increase durability and reduce breakage. They provide enhanced safety when cutting through thick or tough metal materials.

Thin-cut metal cutting disc options are designed for precision cutting, offering cleaner and smoother edges. These discs generate less heat, reducing the chances of warping or discoloration on the metal surface. Professionals prefer thin-cut discs for applications that require high precision, such as automotive and aerospace industries.

Another advanced metal cutting disc is the diamond cutting disc. While primarily used for cutting stone and concrete, some diamond discs are engineered for cutting metal, providing extreme durability and precision. These discs are ideal for industrial applications where longevity and performance are critical.

The right metal cutting disc enhances cutting efficiency, reduces material wastage, and ensures a clean finish. Selecting the right disc based on material thickness, cutting speed, and safety considerations leads to better performance and extended tool life.

115 Cutting Disc Price: Understanding Cost Factors

The 115 cutting disc price varies based on several factors, including material composition, brand, thickness, and intended use. Understanding these factors helps buyers make informed decisions and get the best value for their investment.

One of the primary factors affecting the 115 cutting disc price is the type of abrasive material used. Standard aluminum oxide discs are generally more affordable, while premium zirconia or ceramic-infused discs offer better durability and cutting performance at a higher cost. Diamond-edged discs, although more expensive, provide longer service life, making them cost-effective in the long run.

The thickness of the disc also plays a role in the 115 cutting disc price. Thinner discs tend to be more expensive as they offer precision cutting with minimal material wastage. Thicker discs, while more affordable, are often used for rough cutting applications where precision is less critical.

Brand reputation is another key factor. Established brands with a history of producing high-quality cutting discs tend to price their products higher due to better quality control, enhanced safety features, and longer durability. However, generic or lesser-known brands may offer lower 115 cutting disc price but may compromise on longevity and performance.

Packaging and quantity purchases also influence the 115 cutting disc price. Buying in bulk often leads to cost savings, making it a smart choice for professionals who require a steady supply of cutting discs. Some manufacturers also offer discounted rates for wholesale purchases.

While affordability is important, it is essential to consider the balance between price and quality. Investing in a slightly higher 115 cutting disc price from a reputable brand ensures better cutting efficiency, reduced downtime, and enhanced safety.

Metal Cutting Disc Sizes: Choosing the Right Dimension

Selecting the appropriate metal cutting disc sizes is essential for achieving precise and efficient cuts in metalworking applications. Different disc sizes are designed for specific tasks, and using the correct size ensures safety, accuracy, and optimal performance.

One of the most commonly used metal cutting disc sizes is 115mm (4.5 inches). This size is popular among professionals and DIY users due to its versatility and ease of handling. It is ideal for cutting thin to medium-thickness metals and is widely used in construction, automotive, and fabrication industries.

For heavier-duty applications, 125mm (5 inches) and 150mm (6 inches) metal cutting disc sizes provide increased cutting depth and durability. These discs are suitable for cutting thicker metal sheets, pipes, and structural components. They offer a balance between precision and power, making them a preferred choice for industrial use.

Larger metal cutting disc sizes, such as 180mm (7 inches) and 230mm (9 inches), are used for heavy-duty cutting applications where deep cuts are required. These discs are commonly used in industrial and construction projects where thick metal beams and large components need to be cut efficiently.

The choice of metal cutting disc sizes depends on the grinder’s compatibility and the type of work being performed. Using the correct disc size improves cutting efficiency, enhances safety, and ensures the best possible results.

Metal Cutting Disc FAQs

What is the best angle grinder disc for cutting steel?

The best angle grinder disc types for steel include thin-cut cutting discs for precision, reinforced discs for durability, and diamond-edged discs for extended service life. Choosing the right disc depends on the steel thickness and desired finish.

How much does a 115mm cutting disc cost?

The 115 cutting disc price varies based on material quality, brand, and thickness. Basic aluminum oxide discs start at lower prices, while premium zirconia or diamond discs cost more but provide longer durability and efficiency.

Which metal cutting disc is best for stainless steel?

For stainless steel, thin-cut, high-performance metal cutting disc options with ceramic or zirconia abrasives are recommended. These discs reduce heat buildup, minimizing discoloration and ensuring a clean, burr-free cut.

How do I choose the right metal cutting disc size?

The right metal cutting disc sizes depend on the grinder compatibility and cutting depth required. For general use, 115mm or 125mm discs work well, while larger sizes like 180mm or 230mm are best for industrial applications.

Can a metal cutting disc be used for grinding?

No, a metal cutting disc should not be used for grinding. Cutting discs are thinner and designed for slicing through metal, while grinding discs are thicker and meant for material removal. Using the wrong disc can cause breakage and safety hazards.

Post time:4월 - 29 - 2025