factory customized Flap Disc For Sanding Wood – Marble Granite 115mm 4 1/2" Abrasive Silicon Carbide Flap Wheel – Double Goats

factory customized Flap Disc For Sanding Wood – Marble Granite 115mm 4 1/2" Abrasive Silicon Carbide Flap Wheel – Double Goats Detail:

Marble Granite 115mm 4 1/2″ Abrasive Silicon Carbide Flap Wheel

Description

| Abrasive: | Aluminium Oxide SA | Color: | Black |

|---|---|---|---|

| Hardness: | R | Max Working Speed: | 80 M/S |

| Grit Size: | 40#,60#,80#,100# | Iterm NO.: | FA11522 |

| Application: | Ferrous Metal And Inox | Bonding Agent: | Resin Bonded |

| Arbor Size: | 5/8 In | Disc Type: | Flat Type |

| High Light: |

115mm Silicon Carbide Flap Wheel, 80M/S Silicon Carbide Flap Wheel, 115mm Abrasive Flap Wheel |

||

115mm (4 1/2″) Silicon carbide abrasive flap discs for marble, granite, cement and non-ferrous metals.

Product details

Flap discs aremanufactured in high quality silicon carbide abrasive on a plastic backing.

The inner ring is made of high-quality material, hard and wear-resistant, with an inner diameter of 22mm and an outer diameter of 115mm. It is specially designed for angle grinders of corresponding specifications.

With high stock removal on coarse grits, performs well on marble, granite, concrete as well as non-ferrous metals and their alloys

.A useful longer lasting alternative to fibre backed discs. Hole size 22.23mm/22mm (7/8″). Grit sizes: P40, 60, 80, 120, 220 and 320.

Applications: Marble and stone Concrete Building materials Non-ferrous metals and their alloys

| Cutting wheel information: | |||

| Product Name | Flap discs for stone | Abrasive | silicon carbide |

| Hardness | R Grade | Safety Standard | EN13743 |

| Max working speed | 80 m/s | OEM Service | Acceptable |

| R.P.M | 13300 | Package | Kraft Carton and Pallet |

| Grit size | 40#60#80#120# | HS Code | 68042210 |

| Certificate | MPA ,ISO9001 | Loading Port | Tianjin or else |

| Iterm | Specifications | Grit | Unit | Qty/box | Qty/Carton | NW | GW | carton(MM) |

| FA10016 | T29-100X16MM | 40# | PC | 50 | 200 | 12 | 13 | 530*250*250 |

| 60# | PC | 50 | 200 | 11 | 12 | |||

| 80# | PC | 50 | 200 | 10 | 11 | |||

| 120# | PC | 50 | 200 | 9 | 10 | |||

| FA11522 | T29-115X22MM | 40# | PC | 50 | 200 | 17 | 18 | 630*270*270 |

| 60# | PC | 50 | 200 | 17 | 18 | |||

| 80# | PC | 50 | 200 | 16 | 17 | |||

| 120# | PC | 50 | 200 | 15 | 16 | |||

| FA12522 | T29-125X22MM | 40# | PC | 50 | 200 | 21 | 22 | 680*290*280 |

| 60# | PC | 50 | 200 | 20 | 21 | |||

| 80# | PC | 50 | 200 | 19 | 20 | |||

| 120# | PC | 50 | 200 | 18 | 19 | |||

| FA15022 | T29-150X22MM | 40# | PC | 25 | 100 | 17 | 18 | 350*350*300 |

| 60# | PC | 25 | 100 | 16 | 17 | |||

| 80# | PC | 25 | 100 | 15 | 16 | |||

| 120# | PC | 25 | 100 | 14 | 15 | |||

| FA18022 | T29-180X22MM | 40# | PC | 25 | 100 | 22 | 23 | 400*400*300 |

| 60# | PC | 25 | 100 | 21 | 22 | |||

| 80# | PC | 25 | 100 | 20 | 21 | |||

| 120# | PC | 25 | 100 | 19 | 20 |

1.What is the better Storage method of grinding wheel?

Store wheels on a suitable position in a dry condition, Never store wheels near excessive heat or cold, in contact with water, oil or moisture.

2.Will inferior abrasive discs cause safety accidents?

If the grinding wheel breaks, the resulting debris is likely to eject at high speed, and may cause serious injury or even death, usually hitting the face and head of the operator. The power of speed is indeed surprising, up to 80 to 100 miles per hour.

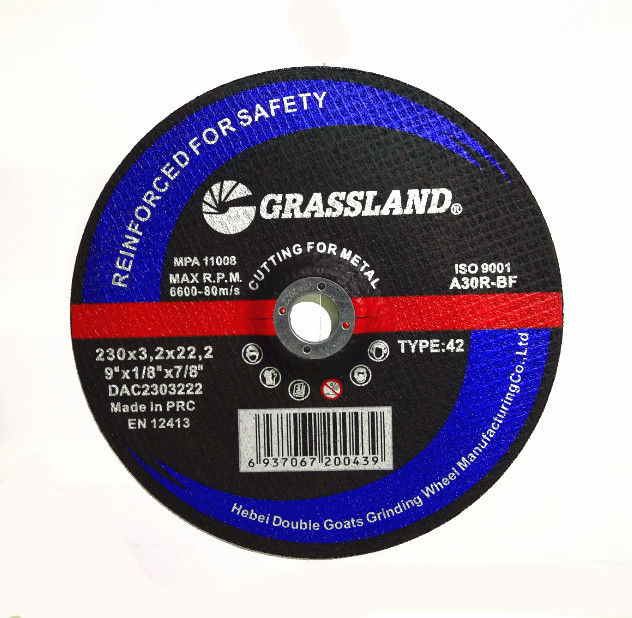

Grassland abrasives discs manufactured to assure operator safety and optimum performance with stable quality, guaranteed to comply with European safety standard EN 12413.

3.Why is it necessary to be equipped with appropriate safety clothing and protection during cutting or grinding fabrication?

During work and grinding, abrasive particles fall off due to friction. These are usually regarded as sparks, which can cause burns to bare skin and are especially damaging if they come into contact with the eyes. If you don’t wear earmuffs for a long time, your hearing will be affected.

Product detail pictures:

Related Product Guide:

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for factory customized Flap Disc For Sanding Wood – Marble Granite 115mm 4 1/2" Abrasive Silicon Carbide Flap Wheel – Double Goats , The product will supply to all over the world, such as: Malaysia, Myanmar, USA, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.