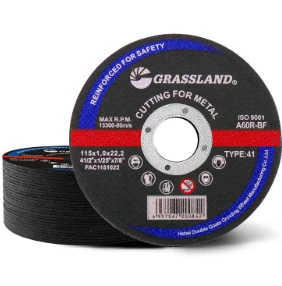

In practice, one can see the utility of 115mm cutting discs in a variety of scenarios. A metal fabrication shop, for instance, heavily relies on these discs for crafting custom metal fixtures and components. Here, the discs’ ability to produce precise cuts with ease speeds up production processes, leading to increased outputs and client satisfaction. In construction, these discs cut through rebar, steel, and concrete, simplifying tasks that would otherwise require more labor-intensive methods. Another advantage lies in their adaptability. Available in different specifications, these discs can be matched with various power tools to optimize performance for specific tasks. This adaptability means that whether you are on a construction site using powerful angle grinders or in a small workshop using compact cutting tools, there’s an appropriate 115mm disc designed to meet those needs. Finally, safety is paramount when using cutting discs. Manufacturers stress the importance of wearing appropriate protective gear such as gloves and goggles to mitigate risks associated with debris and sparks. By following these guidelines, users can operate confidently, knowing they are protected while achieving optimal results. In conclusion, 115mm cutting discs represent an amalgamation of precision, expertise, authority, and trust. Their widespread use across industries is not just due to their cutting capabilities but also because they deliver consistent, high-quality results. For professionals seeking equipment that combines these attributes with cost-effectiveness and performance, 115mm cutting discs are an obvious choice. As these industries evolve and demand increases for precision and efficiency, the role of these discs becomes even more integral to their operations, thus cementing their place as a vital tool in any professional’s arsenal.

Post time:Jan - 28 - 2025