Metal Cutting Disc

Metal cutting discs are specialized tools designed for cutting various types of metal, including steel, aluminum, and stainless steel. These discs are typically made from high-strength materials such as aluminum oxide, silicon carbide, or diamond, which provide durability and efficiency in cutting tasks. They come in various sizes and thicknesses to suit different cutting applications and tools, including angle grinders, chop saws, and table saws.

The primary applications of metal cutting discs include fabrication, construction, automotive repair, and metalworking industries. They are commonly used to cut metal sheets, rods, pipes, and structural components with precision and ease. The sharp edges and robust design allow for quick and efficient cutting, making them essential tools for professionals and DIY enthusiasts alike.

One of the key benefits of using metal cutting discs is their ability to produce clean, burr-free cuts, which is crucial for ensuring the integrity and quality of the finished workpiece. Additionally, these discs are designed to withstand high speeds and pressures, providing longevity and reliability during demanding tasks. Overall, metal cutting discs are vital tools in any workshop where metal cutting is required.

-

-

5 Inch Reinforced Fiberglass Metal Cut Off Discs 125 X 3.2 X 22Mm

-

-

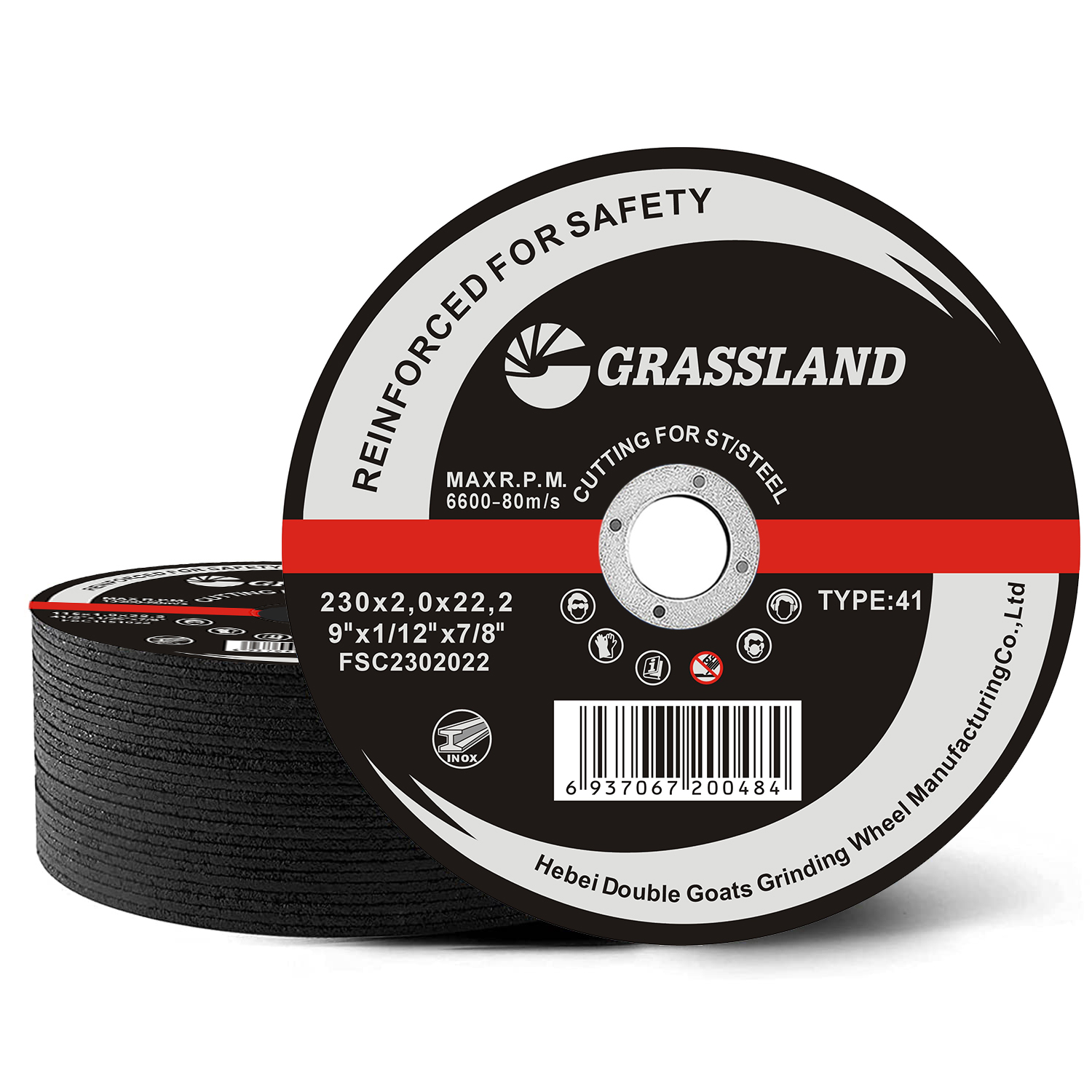

Grassland 9 Inch 230mm X 2 X 22 Stainless steel Carbon Steel Cutting Disc

-

-

Grassland 4.5inch Cutting Disc for Metal Extra Thin Steel Cutting Disc 115 X 1.0 X 22.23mm

-

4.5inch 115mm Cutting And Grinding Discs For Metal 115X3X22.2mm

-

-

-

Grassland 100mm Ultra Thin grinder disc for metal cutting disc 4

-

-

9 Inch 230mm X 3mm X 22.23mm Abrasive Discs For Angle Grinder

How Do You Choose The Right Metal Cutting Disc For Your Project?

Choosing the right metal cutting disc for your project involves several important factors to ensure optimal performance and safety. The first consideration is the material you will be cutting. Different discs are designed for specific materials, such as aluminum, stainless steel, or mild steel. Always check the disc's specifications to ensure compatibility with your workpiece.

Next, consider the thickness of the disc. Thicker discs tend to be more durable and can withstand higher pressures, making them suitable for heavy-duty applications. However, thinner discs allow for faster cuts and less material waste, which may be beneficial for precision work.

The size of the disc is also crucial. Ensure that the disc diameter matches the specifications of your cutting tool, such as an angle grinder or chop saw. Additionally, pay attention to the RPM rating of the disc, as it should not exceed the maximum RPM of your tool to prevent accidents.

Lastly, consider the type of cut you need. Some discs are designed for faster cutting, while others are intended for precision. By evaluating these factors, you can select the most suitable metal cutting disc for your specific project requirements.

What Safety Precautions Should Be Taken When Using Metal Cutting Discs?

Using metal cutting discs involves certain safety precautions to prevent accidents and ensure safe operation. First and foremost, always wear appropriate personal protective equipment (PPE), including safety glasses or goggles to protect your eyes from flying debris, and hearing protection to guard against noise exposure. A dust mask is also recommended, particularly when cutting materials that generate fine particles.

Before using the disc, inspect it carefully for any signs of damage, such as cracks, chips, or warping. Never use a damaged disc, as it can shatter during operation and cause serious injuries. Ensure that the disc is properly mounted on the cutting tool and that it is tightened securely.

When operating the tool, maintain a stable and balanced stance. Use both hands to control the tool, and avoid wearing loose clothing or jewelry that could become entangled in moving parts. Always cut in a well-ventilated area to minimize exposure to fumes and dust.

Lastly, follow the manufacturer's instructions regarding the maximum RPM rating of the disc and the tool. Never exceed this limit, as doing so can lead to disc failure. By adhering to these safety precautions, you can help ensure a safe and effective cutting experience.