Understanding the Versatility of 115mm Metal Grinding Discs

In the world of metalworking, the tools you choose can significantly influence the quality of your work and the efficiency of your processes. Among these tools, grinding discs, especially those measuring 115mm in diameter, are an essential component for many metal fabrication tasks. Whether you are a professional tradesperson or a DIY enthusiast, understanding the applications, advantages, and selection criteria for metal grinding discs can enhance your cutting and grinding experience.

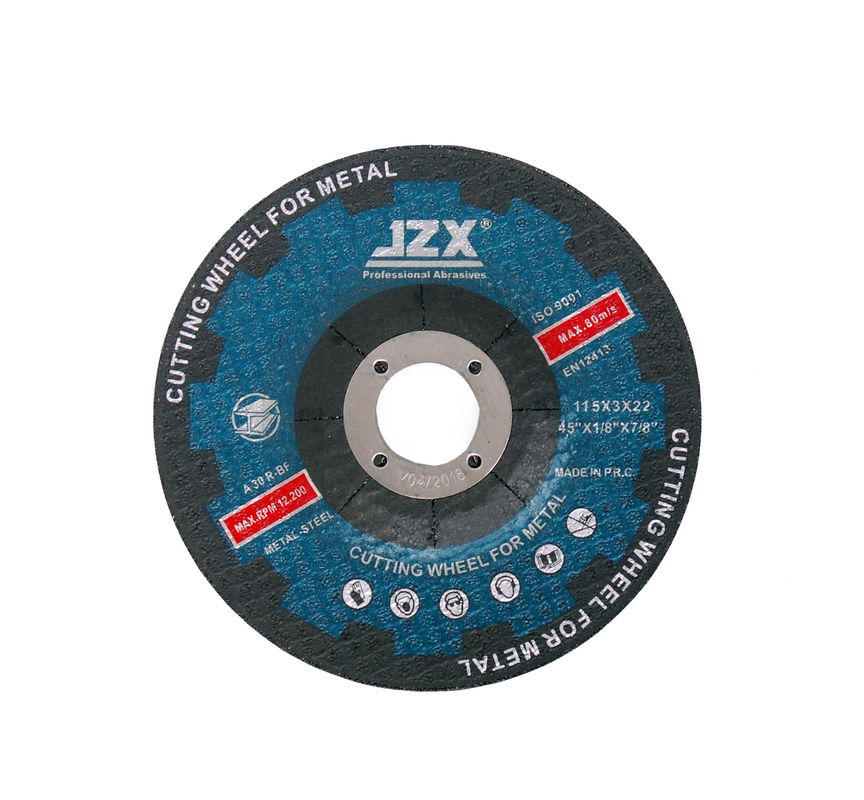

What is a 115mm Metal Grinding Disc?

A 115mm metal grinding disc is a round disc made from abrasive materials designed to grind, cut, or polish metal surfaces. The size, 115mm in diameter, is a common choice, particularly for handheld angle grinders, which can accommodate a wide range of applications from removing welds to cleaning surfaces. The standard thickness of these discs often ranges from 6mm to 7mm, depending on their intended use, with thicker discs providing more durability for heavy-duty tasks.

Applications of 115mm Metal Grinding Discs

These grinding discs are remarkably versatile and can be used across various applications in metalworking

1. Surface Grinding They are ideal for achieving a smooth finish on metal surfaces, effectively removing imperfections, rust, or old paint. 2. Weld Smoothing After welding, excess material can be ground down to create a uniform surface. This is crucial for not only aesthetics but also for ensuring proper fit and functionality in the assembly of parts.

3. Metal Cutting Some 115mm discs are designed for cutting through metal sheets and pipes. They provide precision and can cleanly slice through most ferrous and non-ferrous metals.

4. Surface Preparation Before painting or coating metal products, surface preparation is essential. Grinding discs help clean and etch surfaces to ensure better adherence of paints or coatings.

5. Deburring After machining, sharp edges can pose safety risks and hinder assembly. Grinding discs are effective for removing burrs and sharp edges to ensure safer handling of materials.

Advantages of Using 115mm Metal Grinding Discs

The benefits of using these discs are manifold, making them a favorite among professionals and hobbyists alike

115mm metal grinding disc

- Efficiency A 115mm disc can operate at high speeds, allowing for faster material removal and completion of tasks without compromising quality.

- Cost-Effectiveness Given their high durability and efficiency, investing in quality grinding discs can lead to cost savings in terms of time and tool replacements.

- Ease of Use These discs are designed for compatibility with standard angle grinders, making them accessible and easy to use for most users.

- Safety Features With proper adherence to safety guidelines, including wearing protective gear and using the disc within its intended parameters, users can significantly reduce the risk of accidents.

Selecting the Right 115mm Metal Grinding Disc

When choosing a metal grinding disc, consider the following factors

1. Material Compatibility Ensure the disc is suited for the type of metal you are working with, whether it’s aluminum, stainless steel, or other alloys.

2. Abrasive Type Different discs employ various abrasive materials like aluminum oxide or zirconia. Understanding the properties of these materials can help in choosing one that aligns with your requirements.

3. Disc Thickness Assess the thickness required based on the nature of the task. Thicker discs are recommended for heavier-duty tasks while thinner options are ideal for precise work.

4. Brand Quality Opt for reputable brands known for durability and performance. This choice often results in better outcomes and enhanced safety.

Conclusion

In a nutshell, 115mm metal grinding discs are invaluable tools in the metalworking sector. Their adaptability across various tasks, combined with their efficiency and ease of use, makes them a preferred choice for metalworkers everywhere. By understanding their applications, advantages, and selection criteria, users can make informed decisions that enhance their project outcomes and overall experience in metal fabrication. Whether you’re smoothing out welds or preparing surfaces for painting, the right grinding disc can make all the difference in achieving professional results.

Post time:Nov - 19 - 2024