Understanding 355mm Abrasive Discs Applications and Benefits

Abrasive discs are essential tools in various industries that require cutting, grinding, and polishing materials ranging from metal to wood. Among the different sizes available, the 355mm abrasive disc stands out due to its versatile applications and effectiveness in achieving high-quality finishes. This article delves into the features, applications, and benefits of using 355mm abrasive discs.

What is a 355mm Abrasive Disc?

A 355mm abrasive disc is a circular disc typically made from a blend of abrasives, including aluminum oxide or zirconia, mounted on a backing material. The diameter of 355mm (approximately 14 inches) makes it suitable for use with several grinding machines, including angle grinders and bench grinders. Depending on its composition, the disc can be employed for various grinding applications, such as cutting tough metals, deburring steel, or finishing wood surfaces.

Types of Abrasive Discs

Abrasive discs come in various forms tailored for specific purposes. Common types of 355mm abrasive discs include

1. Cutting Discs Designed primarily for slicing through materials, these discs are incredibly thin and efficient, enabling precise cuts in metals and other hard materials.

2. Grinding Discs Thicker and more robust, grinding discs are meant for more substantial material removal. They are ideal for smoothing rough edges and surfaces.

3. Flap Discs These discs feature layers of abrasive flaps, which provide both grinding and finishing capabilities, making them perfect for achieving a polished look.

4. Surface Conditioning Discs Designed for cleaning, finishing, and polishing surfaces, these discs are essential in industries where aesthetic and functional finishes are paramount.

Applications of 355mm Abrasive Discs

The versatility of 355mm abrasive discs makes them applicable in numerous fields

- Metal Fabrication In metalworking, these discs are used for cutting and grinding metal pieces, enabling fabricators to achieve complex shapes and finishes.

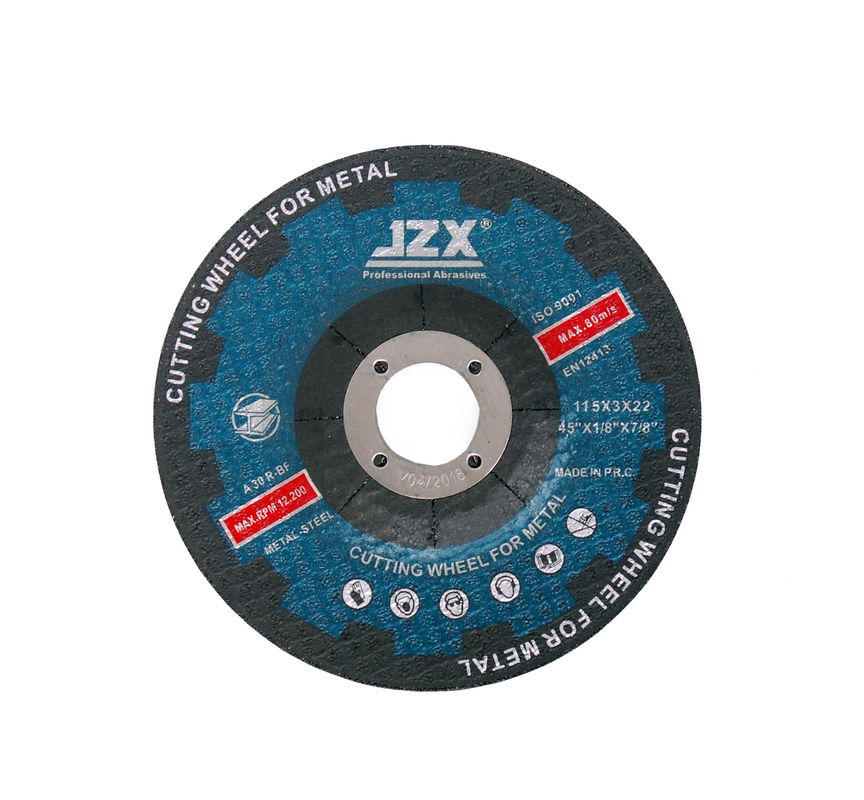

355mm abrasive disc

- Construction In construction, abrasive discs are employed for renovating surfaces, cutting tiles, and working on metal structures.

- Woodworking Woodworkers use 355mm abrasive discs for sanding and finishing wood surfaces, allowing for smooth and refined craftsmanship.

- Automotive Industry The automotive sector utilizes these discs for repairing and modifying metal parts, ensuring precision and efficiency.

- Artistic Applications Sculptors and artists use abrasive discs for shaping materials and achieving desired textures in their works.

Benefits of Using 355mm Abrasive Discs

1. Efficiency A 355mm abrasive disc can significantly reduce the time spent on cutting and grinding tasks. Its larger diameter allows for a wider surface area to be covered, resulting in quicker material removal.

2. Versatility Available in various compositions, these discs can handle a wide range of materials, including steel, aluminum, wood, and plastic, making them invaluable in diverse industries.

3. Cost-Effectiveness Although high-quality abrasive discs may represent a greater initial investment, their durability and efficiency often yield long-term savings by minimizing the frequency of replacements.

4. Quality Finishes The ability to choose specific abrasive discs tailored for particular tasks ensures the achievement of high-quality finishes, which is vital for many manufacturing and artistic processes.

5. Ease of Use Designed for compatibility with common grinding tools, 355mm abrasive discs provide ease of attachment and removal, facilitating quick changes during projects.

Conclusion

In summary, the 355mm abrasive disc is a crucial tool across multiple industries, delivering efficiency and quality in cutting, grinding, and finishing tasks. With its versatility in applications ranging from metal fabrication to woodworking, this abrasive tool demonstrates the importance of selecting the right equipment for specific tasks. Understanding the various types of abrasive discs available and their appropriate applications can significantly enhance productivity and the quality of work, proving that sometimes, the right tool can make all the difference. As industries continue to advance, investing in high-quality abrasive discs remains a smart choice for professionals seeking to maintain excellence in their crafts.

Post time:Dec - 05 - 2024