The 400mm 16 Inch Resin Cutting Disc is a specialized tool designed for efficient and precise metal cutting. Manufactured by Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd., this reinforced resin cutting disc combines durability, safety, and high-performance capabilities to meet the demands of industrial and construction applications. Whether you're working with ferrous metals, stainless steel, or structural components, this cutting disc delivers fast, burr-free results. Below, we explore its key features, technical specifications, and real-world applications.

Key Features of the 400mm 16 Inch Resin Cutting Disc

The 400mm 16 Inch Resin Cutting Disc is engineered with advanced materials and design to ensure optimal performance. Here are its core features:

- High-Quality Abrasive Material: Manufactured using aluminum oxide abrasive grains, this disc offers exceptional cutting efficiency and longevity. The inclusion of heat-treated aluminum oxide and monocrystalline fused alumina (SA) enhances its ability to handle tough materials like angle iron, channel iron, and heavy rebar.

- Reinforced Resin Bonding: The disc is bonded with resin, providing a balance between flexibility and strength. This ensures the disc maintains its structural integrity under high-speed operation, reducing the risk of breakage during use.

- Optimized Hardness and Grit Sizes: With a hardness rating of R and grit sizes ranging from 24# to 60#, this disc is suitable for both coarse and fine cutting tasks. The varied grit options allow users to select the ideal specification for their specific metal-cutting needs.

- High Maximum Working Speed: Designed to operate at a maximum speed of 80 M/S, the disc ensures rapid material removal while maintaining safety and precision.

- Safe and Durable Construction: The disc features a flat cutting disc design with a 1-inch arbor size, making it compatible with most portable chop saws. Its reinforced structure minimizes vibration and enhances user safety during operation.

Technical Specifications Table

| Feature | Details |

|---|---|

| Abrasive Material | Aluminum Oxide, Heat-Treated Aluminum Oxide, Monocrystalline Fused Alumina (SA) |

| Color | Black |

| Hardness | R |

| Max Working Speed | 80 M/S |

| Grit Sizes | 24#, 30#, 46#, 60# |

| Application | Ferrous Metal and Inox (Stainless Steel) |

| Bonding Agent | Resin Bonded |

| Arbor Size | 1 Inch |

| Disc Type | Flat Cutting Disc |

| Compliance | MPA EN 12413 Standard |

Advantages of the 400mm 16 Inch Resin Cutting Disc

The 400mm 16 Inch Resin Cutting Disc offers several advantages that make it a preferred choice for metalworking professionals:

- Enhanced Safety: The reinforced resin bonding and flat disc design reduce the risk of shattering, ensuring safer operation at high speeds. This is particularly critical when working with heavy-duty materials like structural steel.

- Fast and Efficient Cutting: The combination of high-quality abrasive grains and optimized grit sizes allows for rapid material removal without excessive heat buildup, minimizing the risk of warping or damaging the workpiece.

- Cost-Effective: With a long service life and resistance to wear, this disc provides excellent value for money. Its ability to handle a wide range of materials reduces the need for multiple tools, saving time and resources.

- Compliance with Industry Standards: The disc meets the MPA EN 12413 standard, ensuring it adheres to rigorous safety and performance criteria. This certification is a testament to its reliability and quality.

- Versatile Applications: Suitable for both industrial and construction environments, the disc can be used for cutting steel, stainless steel, and other ferrous metals. Its compatibility with portable chop saws makes it a versatile tool for on-site work.

Application Scenarios

The 400mm 16 Inch Resin Cutting Disc is ideal for a wide range of applications, including:

- Construction and Engineering: Used for cutting structural steel, rebar, and other metal components in building and infrastructure projects. Its high-speed operation ensures efficient material processing on construction sites.

- Manufacturing and Fabrication: Suitable for metal fabrication shops that require precise cutting of ferrous metals. The disc's durability and efficiency make it a reliable choice for high-volume production environments.

- Automotive and Machinery Repair: Ideal for cutting and shaping metal parts in automotive workshops and machinery repair facilities. Its ability to handle stainless steel and other alloys makes it a versatile tool for mechanics.

- Heavy Equipment Maintenance: The disc is well-suited for maintenance tasks involving large machinery, such as cutting steel beams or replacing worn-out components. Its reinforced design ensures it can withstand demanding conditions.

- DIY and Small-Scale Projects: Homeowners and small contractors can benefit from the disc's ease of use and affordability. Its compatibility with portable chop saws makes it a practical tool for DIY metalworking tasks.

For more information on resin cutting discs, visit the product page.

About Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd.

Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. is a leading manufacturer of high-quality grinding and cutting tools, specializing in resin cutting discs and other industrial abrasives. Based in China, the company has built a reputation for producing durable, precision-engineered products that meet international standards.

With a focus on innovation and quality control, Hebei Double Goats ensures that its products comply with MPA EN 12413 and ISO 9001 certifications. These standards guarantee that their cutting discs are safe, reliable, and suitable for demanding industrial applications. The company's commitment to excellence is reflected in its state-of-the-art manufacturing facilities and rigorous testing processes.

Hebei Double Goats offers a wide range of grinding and cutting tools, including flat cutting discs, resin cutting wheels, and specialized abrasives for various materials. Their products are distributed globally, serving industries such as construction, automotive, and manufacturing. The company's ability to meet large-scale production demands, with a capacity of 300,000 PCS per day, ensures timely delivery and consistent quality for customers worldwide.

For more details about the company, visit the Hebei Double Goats website.

Why Choose the 400mm 16 Inch Resin Cutting Disc?

The 400mm 16 Inch Resin Cutting Disc stands out in the market due to its combination of performance, safety, and cost-effectiveness. Here's why it's a top choice:

- Superior Cutting Performance: The disc's advanced abrasive technology ensures efficient material removal, even on tough metals like stainless steel. Its resin bonding enhances durability, allowing for extended use without compromising quality.

- Compliance with Global Standards: Meeting the MPA EN 12413 standard, this disc is designed to meet the highest safety and performance benchmarks. This certification provides users with confidence in its reliability.

- Wide Range of Grit Sizes: With options from 24# to 60#, the disc can be tailored to specific cutting needs, whether you're working on coarse or fine materials.

- Compatibility and Convenience: The 1-inch arbor size ensures compatibility with most portable chop saws, making it a versatile tool for both professionals and DIY enthusiasts.

- Cost-Effective Solution: The disc's long service life and ability to handle multiple materials reduce the need for frequent replacements, offering a cost-effective solution for metalworking tasks.

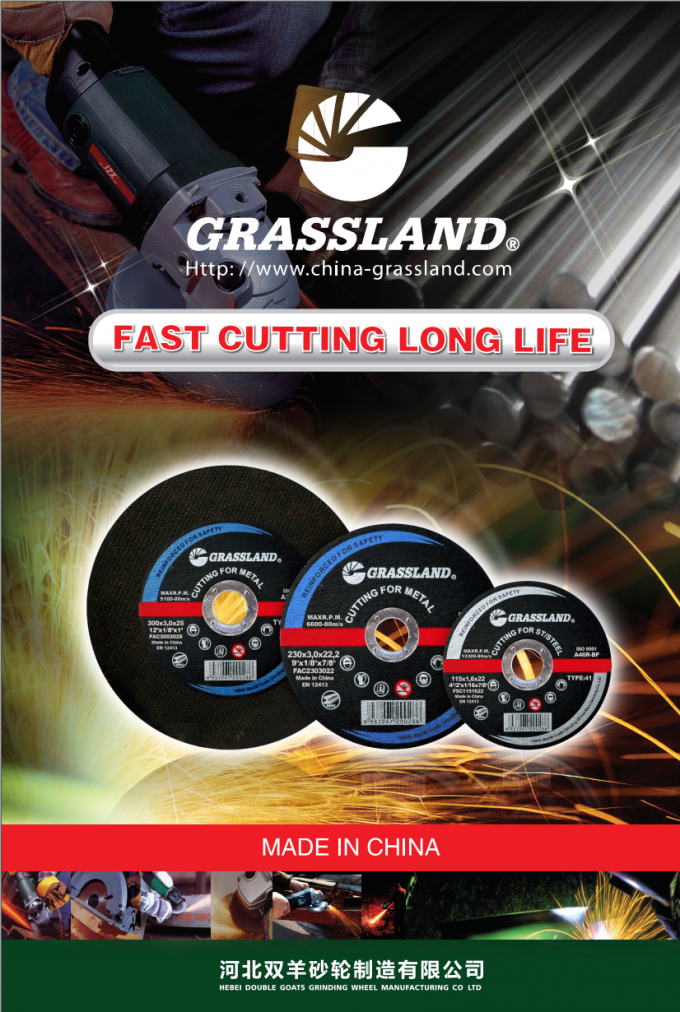

Product Images

Below are images of the 400mm 16 Inch Resin Cutting Disc to provide a visual overview of its design and specifications:

Read More About resin cutting wheel

Read More About 4 grinder flap disc

Read More About flap disc 115mm 60 grit

Authoritative Citations and References

The MPA EN 12413 standard referenced in this article is a critical benchmark for cutting discs and abrasive tools. According to the National Institute of Standards and Technology (NIST), such standards ensure consistency, safety, and performance in industrial applications. NIST's research and development efforts in measurement science and standards play a vital role in advancing manufacturing technologies and ensuring product reliability.

For more information on abrasive tools and cutting disc standards, visit the NIST website.

Post time:Sep - 29 - 2025