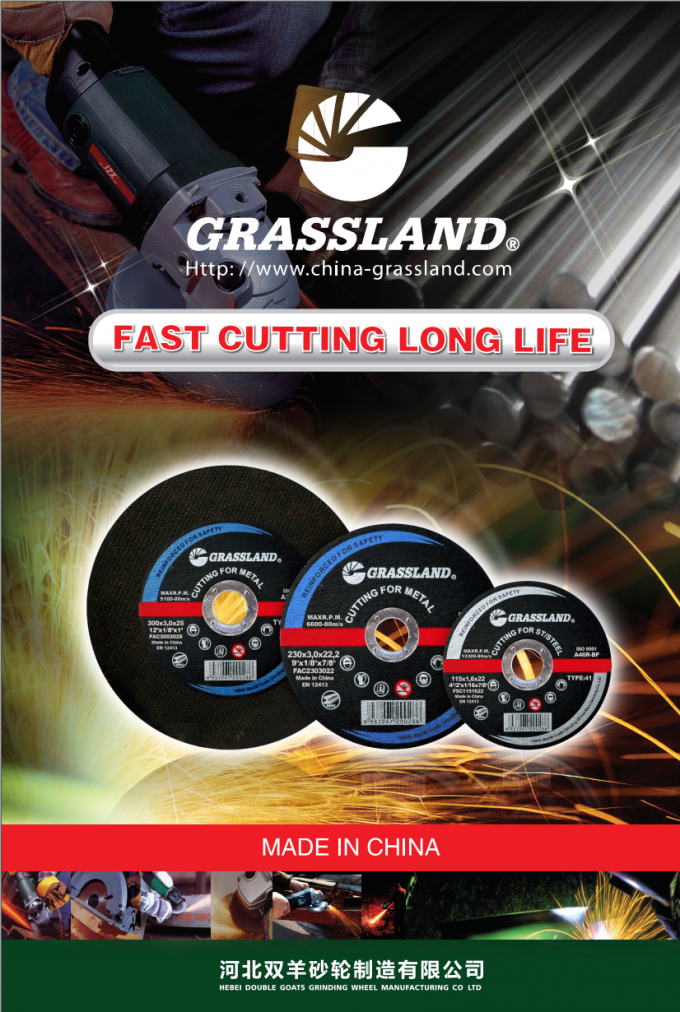

The 400mm 16 Inch Resin Cutting Disc is a specialized tool designed for efficient metal cutting, particularly for ferrous metals and stainless steel. Manufactured by Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd., this reinforced resin cutting disc combines durability, precision, and safety to meet industrial demands. Below is a comprehensive analysis of its features, technical specifications, application scenarios, and the company's background.

Product Overview

The 400mm 16 Inch Resin Cutting Disc is a flat cutting disc engineered for use with portable chop saws and angle grinders. It utilizes aluminum oxide abrasive grains, known for their toughness and heat resistance, ensuring consistent performance even under heavy use. The disc is reinforced with fiberglass and bonded with resin, providing structural integrity and reducing the risk of shattering during operation. This design adheres to the MPA EN 12413 standard, ensuring compliance with international safety and quality benchmarks.

Image: 400mm 16 Inch Resin Cutting Disc for Metal Cutting

Key Features and Advantages

- High Abrasive Efficiency: The use of aluminum oxide ensures fast, burr-free cutting on metals like steel and stainless steel.

- Reinforced Construction: Fiberglass reinforcement enhances durability, making the disc suitable for heavy-duty applications.

- Compliance with Safety Standards: Meets MPA EN 12413 and ISO 9001 certifications, guaranteeing reliability and quality.

- Wide Application Range: Ideal for cutting ferrous metals, angle iron, channel iron, and heavy rebar.

- Low Contamination Risk: The content of iron, sulfur, and chlorine is kept below 0.1%, minimizing the risk of material contamination.

Technical Specifications

| Parameter | Details |

|---|---|

| Abrasive Type | Aluminum Oxide |

| Color | Black |

| Hardness | R |

| Max Working Speed | 80 M/S |

| Grit Size | 24#, 30#, 46#, 60# |

| Arbor Size | 1 In |

| Disc Type | Flat Cutting Disc |

| Application | Ferrous Metal and Inox |

| Bonding Agent | Resin Bonded |

Application Scenarios

The 400mm 16 Inch Resin Cutting Disc is designed for industrial and construction environments where precision and efficiency are critical. Its applications include:

- Structural Metal Cutting: Ideal for cutting angle iron and channel iron in construction projects.

- Heavy Rebar Processing: Efficiently cuts heavy rebar used in concrete reinforcement.

- Stainless Steel Fabrication: Suitable for cutting stainless steel in manufacturing and maintenance tasks.

- Portable Chop Saw Use: Designed for compatibility with portable chop saws, making it a versatile tool for on-site work.

Image: Flap Disc 36 Grit for Surface Preparation

Company Background: Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd.

Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. is a leading manufacturer of industrial abrasives based in China. With a focus on innovation and quality, the company produces a wide range of cutting discs, grinding wheels, and abrasive tools tailored for diverse industries. Their products are certified under ISO 9001 and MPA EN 12413, ensuring adherence to global standards. The company's commitment to precision engineering and customer-centric solutions has established it as a trusted name in the abrasives sector.

Image: 4 Grinder Flap Disc for Metal Surface Treatment

Product Variants and Packaging Details

The 400mm 16 Inch Resin Cutting Disc is available in multiple variants to suit different cutting requirements. Below is a detailed breakdown of the product specifications:

| Description | Item No. | Specification | Unit | PCS/CTN | N.W./G.W. (KGS) | Carton Size (CM) |

|---|---|---|---|---|---|---|

| Flat Cutting Disc for Metal 80 M/S | FAC3003225 | T41-300X3.2X25.4MM | PC | 25 | 13/14 | 30309.5 |

| FAC3004025 | T41-300X4.0X25.4MM | PC | 25 | 14/15 | 303011 | |

| FAC3503225 | T41-350X3.2X25.4MM | PC | 25 | 17/18 | 35.535.59.5 | |

| FAC3504025 | T41-350X4.0X25.4MM | PC | 20 | 17/18 | 35.535.59.5 | |

| FAC4003225 | T41-400X3.2X25.4MM | PC | 25 | 22/23 | 40409.5 | |

| FAC4004025 | T41-400X4.0X25.4MM | PC | 20 | 22/23 | 404011 |

Image: Flap Disc 115mm 60 Grit for Surface Smoothing

Why Choose the 400mm 16 Inch Resin Cutting Disc?

The 400mm 16 Inch Resin Cutting Disc stands out for its combination of performance and safety. Key reasons to choose this product include:

- Enhanced Safety: The reinforced resin bonding reduces the risk of disc failure, ensuring safer operation in high-stress environments.

- Efficient Cutting: The aluminum oxide abrasive allows for rapid material removal without excessive heat buildup.

- Cost-Effective: With a high cutting efficiency and long service life, the disc offers excellent value for money.

- Global Compliance: Certified under MPA EN 12413 and ISO 9001, ensuring reliability and quality assurance.

Industry Standards and Certifications

The 400mm 16 Inch Resin Cutting Disc adheres to strict industry standards to ensure safety and performance. According to the National Institute of Standards and Technology (NIST), compliance with such standards is critical for maintaining product reliability. For example, NIST's research on standards and measurements highlights the importance of rigorous testing for abrasive tools to prevent failures during use. The disc's MPA EN 12413 certification ensures it meets the European Union's safety requirements for cutting discs.

Conclusion

The 400mm 16 Inch Resin Cutting Disc by Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. is a robust, high-performance solution for metal cutting applications. Its reinforced construction, compliance with international standards, and versatility make it an essential tool for industries requiring precision and durability. Whether you're working on construction sites, manufacturing facilities, or maintenance projects, this cutting disc offers the reliability and efficiency needed to meet demanding operational requirements.

References

1. National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov/

2. NIST Standards and Measurements. Retrieved from https://www.nist.gov/standards-codes

Product and Company Links

Post time:Oct - 01 - 2025