Introduction

is a critical tool in industrial and construction applications, designed for efficient and safe cutting of ferrous metals and stainless steel. Manufactured by Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd., this product combines advanced abrasive technology with robust design to meet the demands of modern metalworking. This article explores the features, technical specifications, applications, and company background of this cutting disc, ensuring a comprehensive understanding of its value and performance.Product Overview

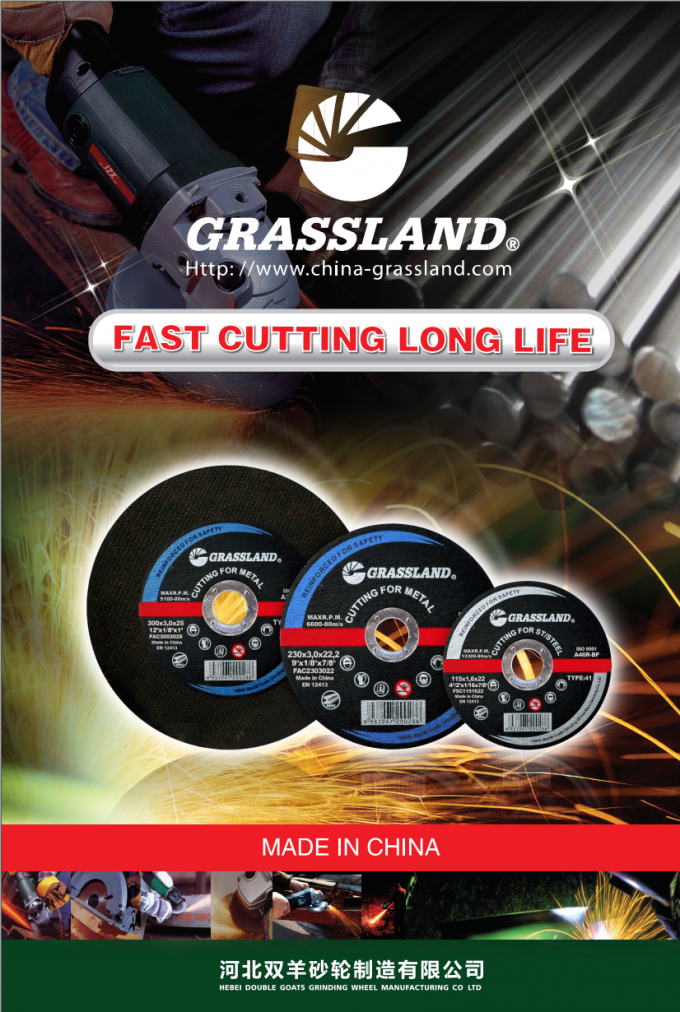

The 400mm Reinforced Resin Cutting Disc is engineered for high-speed cutting operations, offering exceptional durability and safety. Its reinforced structure ensures resistance to high temperatures and mechanical stress, making it ideal for heavy-duty tasks. The disc is available in multiple grit sizes (24#, 30#, 46#, 60#) and specifications, catering to diverse industrial needs.

Key features include:

- Resin Bonding Agent: Ensures stability and longevity under extreme conditions.

- Aluminum Oxide Abrasives: Provides fast, burr-free cutting performance.

- High Working Speed: Operates at up to 80 m/s for efficient material removal.

The product is certified to meet MPA EN 12413 standards, ensuring compliance with international safety and quality benchmarks.

Technical Specifications

| Parameter | Details |

|---|---|

| Abrasive Type | Aluminium Oxide |

| Color | Black |

| Hardness | R |

| Max Working Speed | 80 M/S |

| Grit Size | 24#, 30#, 46#, 60# |

| Application | Ferrous Metal and Inox (Stainless Steel) |

| Arbor Size | 1 In |

| Disc Type | Flat Cutting Disc |

Product Gallery

Applications and Use Cases

The 400mm Resin Cutting Disc is designed for a wide range of industrial applications, including:

- Metal Cutting: Ideal for cutting angle iron, channel iron, heavy rebar, and structural metals.

- Stainless Steel and Steel: Suitable for precision cutting in automotive, construction, and manufacturing sectors.

- Portable Chop Saws: Engineered for use with portable chop saws, ensuring portability and efficiency in field operations.

The disc's resin bonding agent and aluminum oxide abrasives ensure minimal heat generation, reducing the risk of material warping and extending tool life.

Company Background: Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd.

Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. is a leading manufacturer of grinding wheels and cutting discs, based in China. With a commitment to quality and innovation, the company adheres to international standards such as MPA EN 12413 and ISO 9001, ensuring their products meet rigorous safety and performance criteria.

The company's expertise in abrasive technology and production capabilities allow it to supply over 300,000 pieces per day, serving global markets. Their product line includes various types of cutting discs, grinding wheels, and related accessories, tailored to meet the needs of industries ranging from construction to aerospace.

Why Choose This Product?

The 400mm Reinforced Resin Cutting Disc stands out for its combination of performance, safety, and reliability. Key advantages include:

- High Cutting Efficiency: Fast and smooth cutting with minimal effort.

- Durability: Reinforced structure prevents cracking and extends service life.

- Safety Compliance: Certified to meet international safety standards.

For industries requiring precision and reliability, this product is a trusted choice, backed by the company's commitment to quality and innovation.

Conclusion

The 400mm Reinforced Resin Cutting Disc by Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. is a high-performance solution for metal cutting applications. With its advanced abrasive technology, robust design, and compliance with international standards, it is an essential tool for professionals in construction, manufacturing, and beyond. Explore the company's website to learn more about their extensive product range and commitment to quality.

References

National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from https://www.nist.gov

Post time:Sep - 28 - 2025