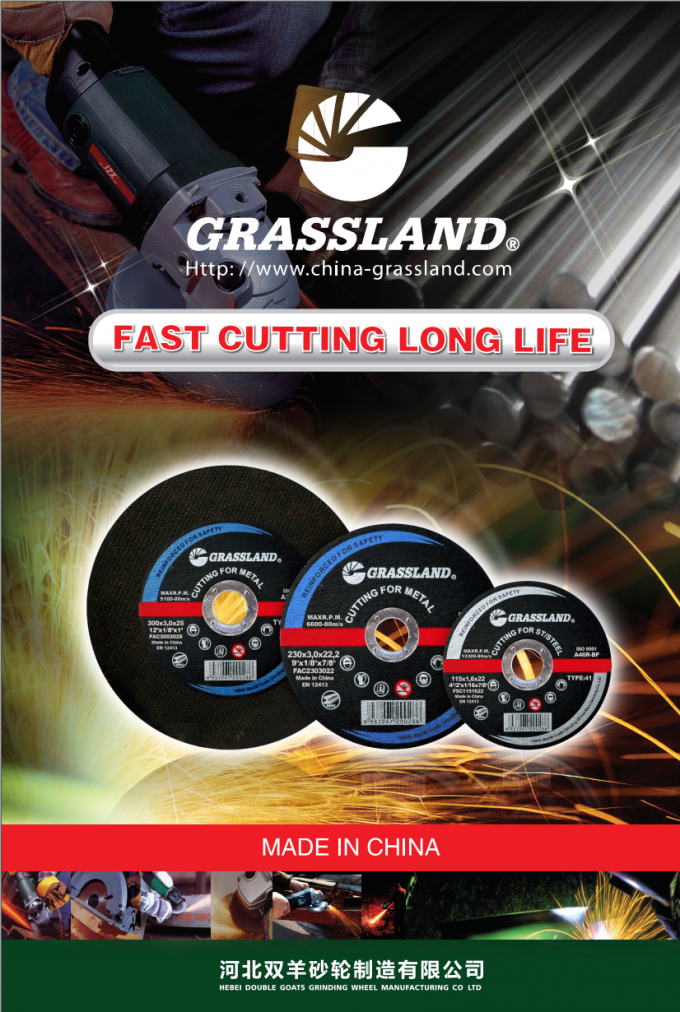

The 400mm Resin Cutting Disc from Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. represents a significant advancement in industrial cutting technology. Designed for precision and durability, this resin cutting wheel is engineered to handle demanding applications involving ferrous metals and stainless steel. With its robust construction and adherence to international standards, this product is a reliable choice for professionals in construction, manufacturing, and metalworking industries.

Key Features and Technical Specifications

The 400mm Resin Cutting Disc is constructed with Aluminium Oxide abrasive grains, known for their high hardness and resistance to wear. This material ensures efficient cutting performance even under heavy use. The disc is Resin Bonded, providing a balance between flexibility and strength, which is critical for maintaining structural integrity during high-speed operations.

| Feature | Details |

|---|---|

| Abrasive Material | Aluminium Oxide |

| Color | Black |

| Hardness | R |

| Max Working Speed | 80 M/S |

| Grit Size | 24#, 30#, 46#, 60# |

| Application | Ferrous Metal and Inox (Stainless Steel) |

| Arbor Size | 1 Inch |

| Disc Type | Flat Cutting Disc |

Advantages and Performance

One of the standout features of the 400mm Resin Cutting Disc is its ability to deliver fast, burr-free cutting. This is achieved through the combination of high-quality Aluminium Oxide abrasive and the Resin Bonded structure. The disc is also designed to meet the MPA EN 12413 Standard, ensuring compliance with rigorous safety and performance requirements.

The 400mm Resin Cutting Disc is particularly effective for cutting angle iron, channel iron, heavy rebar, and other structural metals. Its reinforced construction allows it to withstand high-speed operations without compromising safety. Additionally, the disc's low iron, sulfur, and chlorine content (less than 0.1%) ensures minimal contamination during cutting, which is crucial for maintaining the integrity of the material being cut.

Application Scenarios

The versatility of the 400mm Resin Cutting Disc makes it suitable for a wide range of industrial applications. It is commonly used in portable chop saws, where its flat cutting disc design allows for precise and efficient material removal. This product is ideal for tasks such as cutting stainless steel and steel materials, making it a valuable tool for construction workers, metal fabricators, and maintenance technicians.

For professionals working in environments where high-speed cutting is required, the 400mm Resin Cutting Disc offers a reliable solution. Its max working speed of 80 M/S ensures that operations are completed quickly without sacrificing safety or quality. The disc's resin bonding also enhances its durability, reducing the need for frequent replacements and lowering long-term costs.

Company Background: Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd.

Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. is a leading manufacturer of industrial grinding and cutting products, based in China. The company is committed to producing high-quality resin cutting wheels that meet international standards. With certifications such as MPA EN 12413 and ISO 9001, Hebei Double Goats ensures that its products are not only durable but also safe for use in demanding environments.

As a manufacturer with a focus on innovation, Hebei Double Goats has established itself as a trusted supplier in the global market. The company's supply ability of 300,000 PCS per day demonstrates its capacity to meet the needs of large-scale operations. Additionally, the company offers flexible payment terms, including T/T, L/C, Western Union, and MoneyGram, making it accessible to a wide range of customers.

The 400mm Resin Cutting Disc is just one example of the company's dedication to quality and performance. By leveraging advanced manufacturing techniques and rigorous quality control processes, Hebei Double Goats ensures that its products deliver consistent results across various applications.

Compliance and Safety Standards

The 400mm Resin Cutting Disc is designed to meet the MPA EN 12413 Standard, which outlines the safety requirements for cutting discs used in industrial applications. This certification ensures that the product undergoes rigorous testing for performance, durability, and safety, providing users with confidence in its reliability.

In addition to meeting MPA EN 12413, the product is also compliant with ISO 9001, a globally recognized standard for quality management. This certification underscores Hebei Double Goats' commitment to maintaining high standards in product development and manufacturing processes.

For users concerned about the environmental impact of their tools, the 400mm Resin Cutting Disc is manufactured with low iron, sulfur, and chlorine content (less than 0.1%). This not only enhances the cutting performance but also minimizes the risk of contamination, making it a more environmentally friendly option compared to other cutting discs on the market.

Conclusion

The 400mm Resin Cutting Disc from Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. is a high-performance solution for cutting ferrous metals and stainless steel. With its advanced Aluminium Oxide abrasive, Resin Bonded structure, and compliance with international standards, this product is an essential tool for professionals in the construction and manufacturing industries.

For more information about the 400mm Resin Cutting Disc and other products from Hebei Double Goats, visit the company's product page or explore the company website.

References

1. MPA EN 12413 Standard - This standard specifies the requirements for cutting discs used in industrial applications. For more information, visit the National Institute of Standards and Technology (NIST) website.

2. ISO 9001 Certification - ISO 9001 is an international standard for quality management systems. Learn more about ISO standards at the NIST website.

3. NIST Research on Material Standards - NIST provides extensive research on material properties and standards. Explore their resources at https://www.nist.gov.

Post time:Sep - 29 - 2025