Understanding 9% Metal Cutting Discs Efficiency and Applications

Metal cutting discs play a vital role in various industries, including construction, automotive, and manufacturing. Among the numerous types available in the market, the 9% metal cutting disc stands out for its unique characteristics and advantages. In this article, we will explore what a 9% metal cutting disc is, its applications, benefits, and how to choose the right one for your specific needs.

What is a 9% Metal Cutting Disc?

A 9% metal cutting disc refers to a cutting wheel used for slicing through different types of metals. The 9% typically indicates the concentration of abrasive materials present in the disc. These discs are constructed using a mix of abrasive materials like aluminum oxide, silicon carbide, or diamond, combined with a bonding agent to maintain structural integrity and durability. The efficiency of these discs is highly influenced by their composition, grain size, and the bond type, which are tailored to optimize performance for specific metal cutting tasks.

Applications of 9% Metal Cutting Discs

These cutting discs are widely utilized across several sectors. Their primary applications include

1. Metal Fabrication In fabrication shops, 9% cutting discs are essential for cutting sheets, tubes, and rods of various metals such as steel, stainless steel, and aluminum. Their precision and efficiency make them ideal for creating intricate designs and components.

2. Construction Workers in the construction industry rely on these discs for their ability to cut through rebar, metal stud framing, and other structural components. This versatility helps streamline processes and maintain the integrity of the projects.

3. Automotive Repair Mechanics often use 9% metal cutting discs to cut exhaust pipes, chassis components, and other parts during repairs and modifications. These discs provide clean cuts, reducing the need for further finishing work.

4. Art and Craft Artists and metalworkers can leverage 9% discs for creating sculptures, decorative pieces, and custom metalwork, benefiting from the precision and control these tools offer.

Benefits of Using 9% Metal Cutting Discs

Choosing a 9% metal cutting disc comes with several advantages

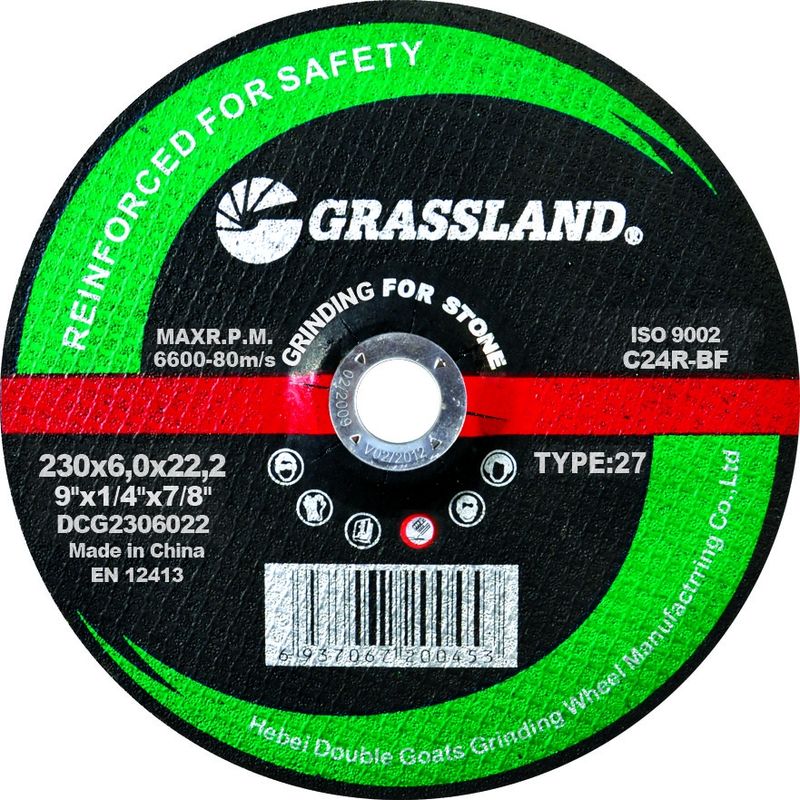

9 metal cutting disc

- High Efficiency The concentrated abrasive compounds allow for faster cutting speeds and reduce the overall time taken for metal cutting tasks

.- Longevity Due to their robust composition, these discs often have a longer lifespan compared to lower-quality alternatives. This durability not only cuts costs but also enhances productivity by minimizing downtime.

- Precision Cuts With the right technique, users can achieve clean and accurate cuts, which is crucial in applications requiring tight tolerances.

- Versatility 9% metal cutting discs can be used for a variety of metals, making them a versatile tool for professionals across different trades.

Choosing the Right 9% Metal Cutting Disc

When selecting a 9% metal cutting disc, consider the following factors to ensure optimal performance

1. Material Compatibility Make sure the disc is suitable for the specific type of metal you will be cutting. Some discs are more effective for ferrous metals while others excel with non-ferrous ones.

2. Size and Thickness The diameter and thickness of the disc will dictate its cutting speed and the type of cuts you can achieve. For precise tasks, thinner discs are often preferred.

3. Speed Rating Ensure the disc can handle the RPM of your cutting tool. Using a disc at a speed higher than its rated limit can lead to breakage and potentially dangerous situations.

4. Application Consider the specific cutting needs. For instance, a disc designed for heavy-duty industrial use may not be necessary for light metalwork.

Conclusion

The 9% metal cutting disc represents an efficient, durable, and versatile solution for various metal cutting tasks. Whether in a fabrication shop, construction site, or an artistic studio, these discs enhance productivity and precision. By understanding their composition, applications, and the factors influencing their performance, users can make informed choices that meet their specific cutting needs effectively. Investing in quality cutting discs can make a significant difference in the overall success of metalworking projects.

Post time:Dec - 19 - 2024