The Versatile World of Aluminium Oxide Cutting Discs

Aluminium oxide cutting discs are an essential tool in various industrial and DIY applications, renowned for their efficiency, durability, and versatility. These specialized discs are designed to cut through a variety of materials, including metals, ceramics, and plastics, making them an indispensable component of many workshops and construction sites. This article explores the characteristics, benefits, and applications of aluminium oxide cutting discs, highlighting their importance in the realm of cutting tools.

What is Aluminium Oxide?

Aluminium oxide, also known as alumina, is a chemical compound comprised of aluminium and oxygen. It is a robust and versatile material that possesses excellent hardness and thermal stability, making it ideal for abrasive applications. Its natural crystalline structure contributes significantly to the cutting efficacy of aluminium oxide cutting discs. When used as an abrasive, it can withstand high temperatures and remains effective over prolonged periods, ensuring consistent performance during use.

Characteristics of Aluminium Oxide Cutting Discs

Aluminium oxide cutting discs are characterized by their grit composition, which determines their cutting efficiency and surface finish. The discs are typically available in various grit sizes, allowing users to choose the most suitable disc for specific tasks. A finer grit provides a smoother finish, while a coarser grit enables faster cutting.

The construction of these discs also includes a bonding agent that holds the abrasive particles together. The most common bonding agents used are resin or vitrified bonds, which offer different levels of durability and performance. Resin-bonded discs are known for their flexibility and versatility, making them suitable for various applications, whereas vitrified bonds offer enhanced rigidity and can withstand higher grinding pressures.

Advantages of Using Aluminium Oxide Cutting Discs

1. Versatility Aluminium oxide cutting discs can efficiently cut through metals, wood, plastics, and ceramics. This adaptability makes them a preferred choice for different industries, including construction, automotive, and metalworking.

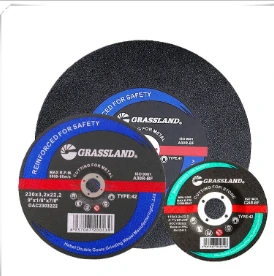

aluminium oxide cutting disc

3. Durability The hardness of aluminium oxide contributes to the longevity of the cutting discs. They can maintain their cutting ability over extended periods, reducing the need for frequent replacements.

4. Heat Resistance Aluminium oxide can withstand high temperatures without losing its cutting ability, making these discs suitable for high-speed cutting applications where heat generation is a concern.

5. Fine Finish The variety of grit sizes available allows users to achieve precise cuts and fine finishes, catering to projects that require a high level of detail.

Applications of Aluminium Oxide Cutting Discs

The applications of aluminium oxide cutting discs are extensive and varied. In the metalworking industry, they are commonly used for cutting steel, stainless steel, and aluminum. They are also favored for sheet metal fabrication, where precision and efficiency are crucial.

In the construction sector, these discs can be used for cutting tiles, concrete, and bricks, with ceramic options enabling smooth cutting through tough materials. Their versatility also extends to woodworking projects, where they can efficiently cut slip-resistant surfaces or intricate designs.

Furthermore, aluminium oxide cutting discs are frequently employed in automotive repair, where they are used to cut through various metals and remove rust or old paint from surfaces. Their ability to operate effectively with high RPM tools makes them ideal for hand-held grinders and stationary cutting machines alike.

Conclusion

Aluminium oxide cutting discs are invaluable tools that cater to a wide range of cutting and grinding needs across multiple industries. Their combination of durability, versatility, and cost-effectiveness makes them a go-to choice for professionals and hobbyists alike. As technology advances, we can expect to see further improvements in the formulation and manufacturing of these cutting discs, ensuring they continue to meet the evolving demands of users worldwide. By understanding the characteristics and applications of aluminium oxide cutting discs, one can harness their full potential to achieve outstanding results in cutting tasks.

Post time:Dec - 12 - 2024