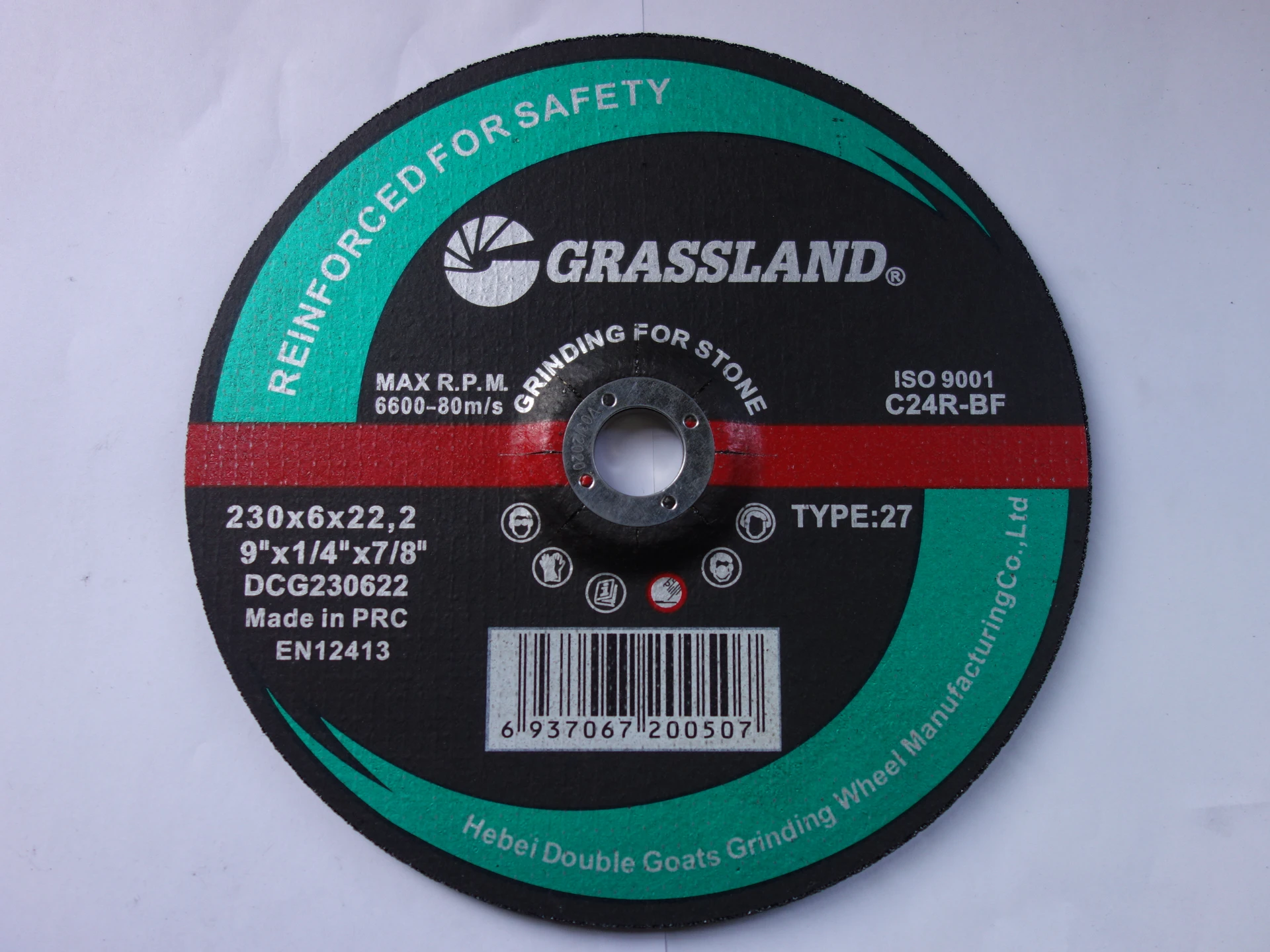

Safety is another critical consideration in the usage of aluminum oxide cut-off wheels. The design of these wheels incorporates features that mitigate risk, such as reduced vibration, which decreases operator fatigue and enhances control over precision tasks. Furthermore, their robustness ensures fewer breakages under stress, which significantly lowers the risk of accidents in the workshop, fortifying the trust professionals place in these tools. From an expertise standpoint, selecting the right aluminum oxide cut-off wheel requires understanding the specific needs of the task at hand. Professionals take into account factors such as the type of metal being cut, the required speed of operation, and the desired quality of the finish. The choice of wheel thickness is also crucial; thinner wheels deliver faster cuts with finer finishes, while thicker wheels offer durability for more demanding tasks. Brand reputation also plays a role in the selection process, with renowned manufacturers offering enhanced features such as reinforced cores and heat resistance, which further solidify their authority in the market. In selecting a brand, professionals often rely on peer reviews and industry certifications to guide their choices, valuing the credibility and trustworthiness derived from consistent performance. The environmental impact of aluminum oxide cut-off wheels is an emerging area of interest. As industries strive to adopt more sustainable practices, the recyclability of these tools is an essential factor. Responsible disposal and potential for material reclamation ensure that their usage aligns with sustainable manufacturing practices, echoing a broader commitment to environmental consciousness. In conclusion, the aluminum oxide cut-off wheel stands as a crucial component in the toolkit of professionals who require precision, efficiency, and reliability in metal cutting and shaping operations. Its unparalleled performance and enduring quality continue to underscore its indispensability in both industry and craft. As technology progresses, further innovations in the composition and application of these wheels are anticipated, promising even greater advancements in cutting-edge tool solutions. The prevalence and adaptability of these wheels unequivocally affirm their position as cornerstones in metalworking and beyond.

Post time:Feb - 10 - 2025