Understanding Angle Grinder Discs for Metalworking

Angle grinders are versatile power tools widely used in metalworking, fabrication, and construction. One of the key components of an angle grinder is the disc, which plays a crucial role in determining the efficiency and quality of the work. Among various types of discs available, those designed specifically for metal are essential for achieving optimal results. In this article, we will explore the different types of angle grinder discs for metal and their applications, materials, and selection criteria.

Types of Angle Grinder Discs for Metal

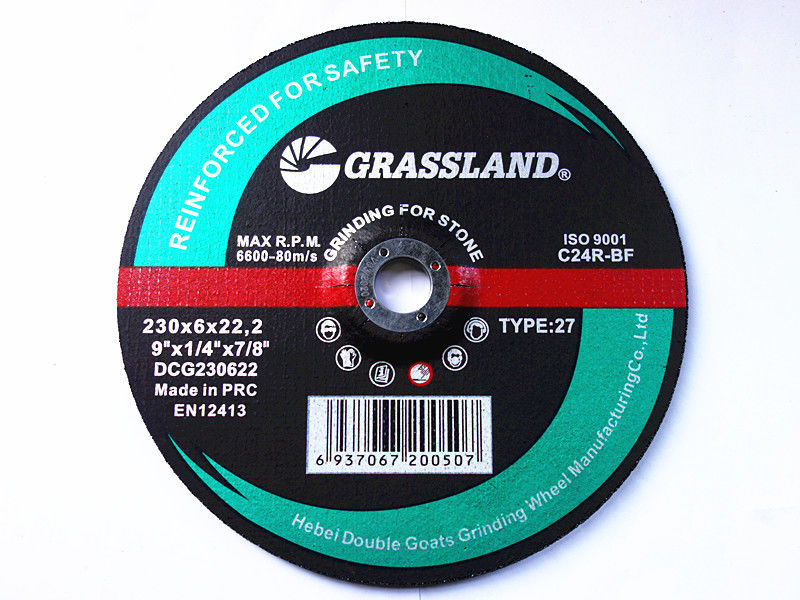

1. Grinding Discs These are designed for the primary purpose of grinding metal surfaces. They are ideal for removing excess material, smoothing rough edges, and preparing surfaces for welding or painting. Grinding discs typically come in various grits, allowing users to choose the appropriate level of abrasiveness based on the task.

2. Cutting Discs Cutting discs are essential for slicing through metal with precision. They are thinner than grinding discs, allowing for cleaner and more accurate cuts. Often made from aluminum oxide or zirconia, cutting discs can effectively work on steel, stainless steel, and other metal materials. Their design minimizes the heat generated during cutting, reducing the risk of warping or damaging the workpiece.

3. Flap Discs These discs consist of overlapping layers of abrasive material, creating a flexible surface ideal for finishing work. Flap discs can be used for grinding, blending, and polishing metal surfaces. Their unique design allows for better control and reduces the risk of gouging the material. Flap discs are often favored for their ability to achieve a smooth finish, making them popular in metal fabrication and repair.

4. Wire Brush Discs Wire brush discs are used for cleaning and removing rust, paint, or other contaminants from metal surfaces. They come in various bristle types and can effectively prepare surfaces for further treatment, such as welding or painting. Wire brushes can be aggressive, so they should be used carefully to avoid damaging the base metal.

Materials Used in Metal Discs

The material of the angle grinder disc significantly affects its performance. Common materials include

angle grinder disc metal

- Aluminum Oxide This is a standard abrasive material used in most grinding and cutting discs. It provides a good balance of performance and cost, making it an ideal choice for general-purpose metalworking. - Zirconia Alumina Known for its durability, zirconia alumina discs are suitable for high-pressure applications and are used in heavy metal grinding tasks. They maintain their cutting ability even at elevated temperatures.

- Ceramic Ceramic abrasives are designed for heavy-duty applications and offer excellent performance on hard metals. They are specifically engineered to last longer and provide faster cutting rates than traditional materials.

Selecting the Right Discs

When choosing angle grinder discs for metalworking, consider the following factors

- Material Type Choose a disc based on the type of metal you are working with. Different materials may require specific types of abrasive properties.

- Disc Thickness Thicker discs offer more durability and are suited for heavier tasks, while thinner discs are better for precision cuts.

- Grit Size For grinding, select a grit size that corresponds to the level of material removal you require. Finer grits provide smoother finishes, while coarser grits remove material faster.

- Compatibility Ensure that the disc is compatible with your angle grinder in terms of size and RPM rating.

In conclusion, angle grinder discs for metal are pivotal in ensuring effective and precise metalworking. By understanding the various types and materials available, users can select the right disc to meet their specific needs, improving both the efficiency and quality of their work. Always prioritize safety by following the manufacturer’s guidelines and using appropriate personal protective equipment while operating an angle grinder.

Post time:Nov - 27 - 2024