Understanding Angle Grinder Grinding Discs for Metal A Comprehensive Guide

Angle grinders are versatile tools used in various applications, from metalworking to construction. One of the essential components of an angle grinder is the grinding disc, particularly when it comes to metal fabrication. Understanding the different types of grinding discs available and how to select the right one for your specific project can significantly impact the efficiency and quality of your work.

Types of Grinding Discs for Metal

When it comes to grinding metal, there are several types of discs to consider, each designed for specific tasks

1. Depressed Center Grinding Discs These are the most common type used on angle grinders. They come in various diameters and are designed for grinding and cutting metal, making them an essential addition to any metalworking toolkit. Typically made from aluminum oxide or zirconia, they offer excellent durability and performance.

2. Flap Discs Comprising multiple layers of abrasive flaps, these discs are excellent for blending, finishing, and light grinding tasks. Flap discs provide a smooth finish and are ideal for use on contoured metal surfaces. They come in various grits, so you can choose one that suits your desired finish.

3. Cutting Discs These thin discs are primarily used for cutting through metal rather than grinding it down. They can effectively slice through various types of metal, including steel and aluminum. Their slim profile allows for precise cuts with minimal material loss.

4. Surface Conditioning Discs These discs are designed to prepare surfaces for further treatment, such as coatings or painting. They are typically made from non-woven nylon and are excellent for removing rust, paint, and other contaminants from metal surfaces.

Selecting the Right Grinding Disc

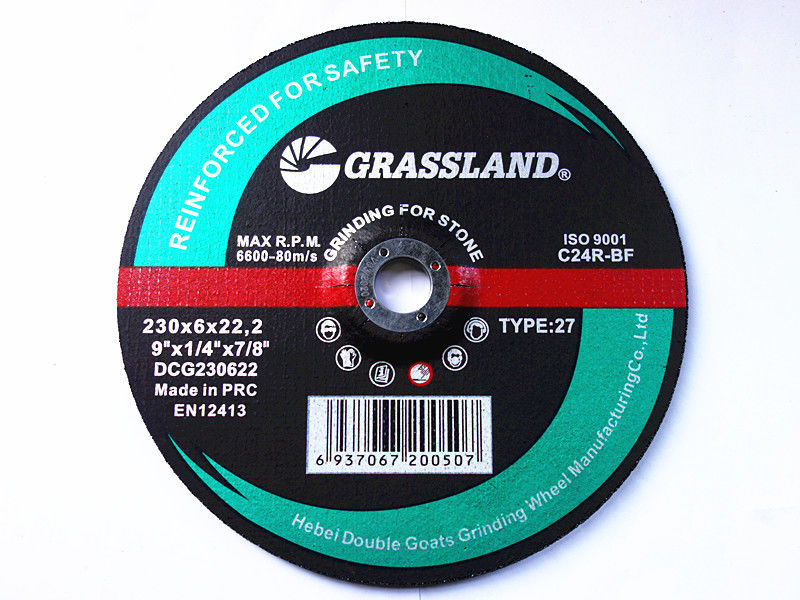

angle grinder grinding discs for metal

Choosing the right grinding disc for your angle grinder depends on several factors, including the type of metal you are working with, the thickness of the material, and the nature of the work. Here are some tips to help you make the right choice

1. Material Type Different metals require different types of abrasives. For instance, aluminum oxide discs are great for steel, while Zirconia discs are better suited for tougher metals.

2. Grit Size The grit size indicates the coarseness of the disc, with lower numbers being more abrasive (e.g., 36 grit) and higher numbers being finer (e.g., 100 grit). For heavy material removal, opt for a lower grit size, while a higher grit is preferred for finishing work.

3. Disc Thickness Thinner discs are ideal for cutting, while thicker ones are suited for grinding. If your primary goal is to grind down surfaces, a thicker disc may provide better stability and longevity.

4. Tool Compatibility Always ensure that the disc you choose is compatible with your angle grinder's RPM (revolutions per minute). Exceeding the maximum RPM can be dangerous and may lead to disc failure.

Safety First

When using angle grinders and grinding discs, safety should always be your top priority. Ensure you wear appropriate personal protective equipment, including safety goggles, gloves, and a face shield. Additionally, secure the workpiece, and be aware of your surroundings to minimize accidents.

Conclusion

Angle grinders equipped with the correct grinding discs for metal can dramatically improve your efficiency and the quality of your work. By understanding the various types of discs available, their uses, and how to select the right one for your project, you can maximize the performance of your angle grinder. Whether you are cutting, grinding, or finishing metal surfaces, the right tools and a mindful approach to safety will ensure that you achieve the best results every time.

Post time:Dec - 11 - 2024