Carbon Steel Cutting Disc is a key solution in the industrial supplies industry, specifically within Abrasive and grinding tools and cutting disc. This article explores how Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Carbon Steel Cutting Disc Overview

- Benefits & Use Cases of Carbon Steel Cutting Disc in cutting disc

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial supplies

- Conclusion on Carbon Steel Cutting Disc from Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd.

Carbon Steel Cutting Disc Overview

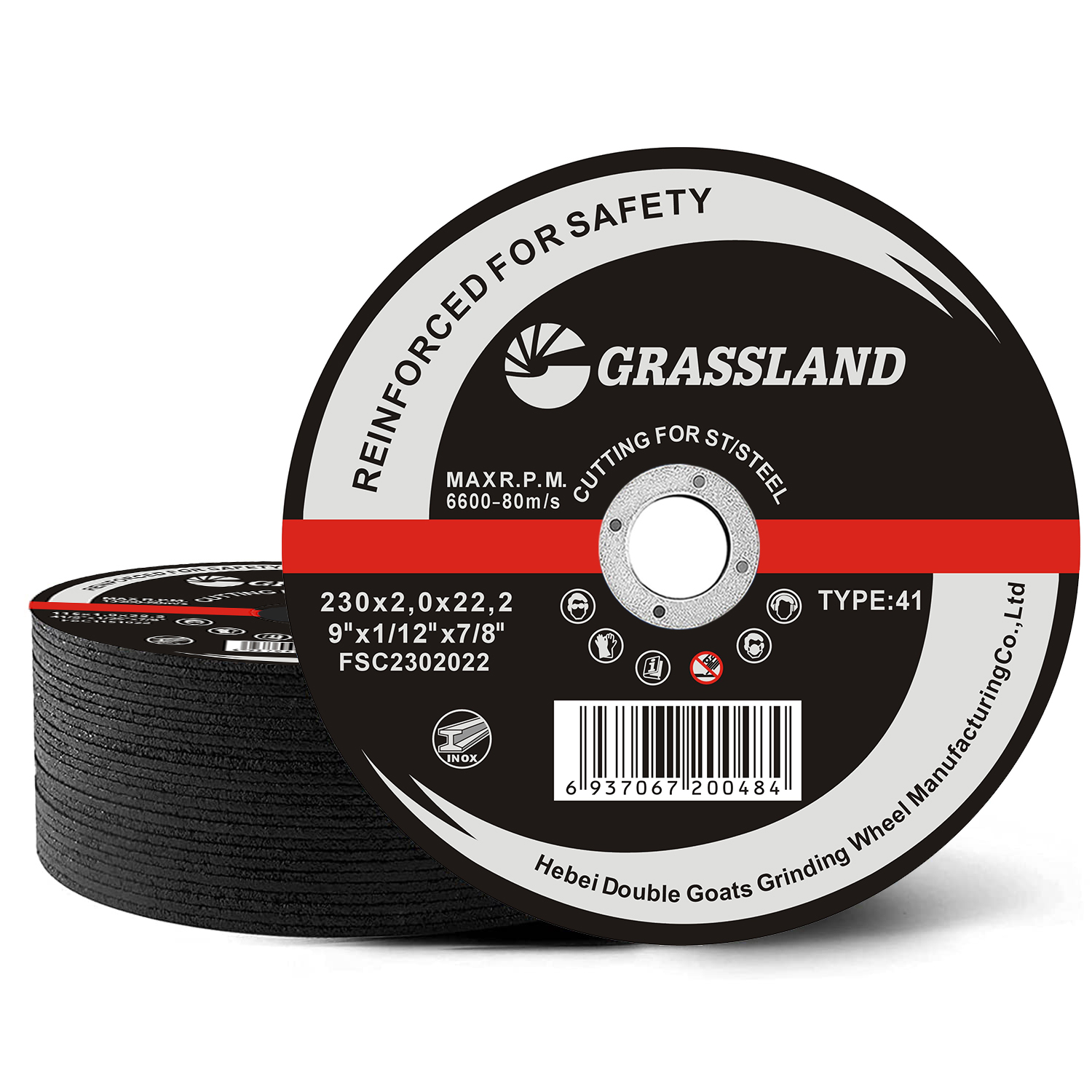

A Carbon Steel Cutting Disc is a resin-bonded, fiberglass-reinforced abrasive wheel engineered for fast, straight cuts through carbon steel and mild steel, and it is also suitable for stainless applications when formulated accordingly. Within industrial supplies—especially the Abrasive and grinding tools category—this cutting disc is a dependable consumable for fabrication, construction, and maintenance teams using angle grinders. The Grassland 9-inch (230mm x 2.0mm x 22.23mm) format helps users achieve thin-kerf, low-resistance cuts that reduce heat input and minimize rework.

Typical technical attributes include an aluminum oxide grain blend for a sharp initial bite and sustained cutting rate, a 2.0mm thickness for speed and precision, and a flat Type 41/Type 1 profile for stable, accurate cut-off operations. When used within recommended parameters (e.g., compatible flanges, correct guard, and adhering to the tool’s max RPM—commonly up to 80 m/s or roughly 6,600 RPM for 230mm wheels), these discs deliver consistent performance across plate, tube, and structural shapes. Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd., under the Grassland brand, is recognized by B2B buyers for reliable quality control, dependable availability, and practical product support—key factors in keeping production lines moving.

Benefits & Use Cases of Carbon Steel Cutting Disc in cutting disc

In day-to-day shop work, a carbon cutting disc is indispensable for cutting carbon steel sheet, tubing, rebar, angle iron, channel, and beams. Field crews use the 230mm size for onsite fabrication, fit-up, and demolition tasks where portable, accurate cut-off is needed. In OEM and metal fabrication, it is often paired with high-power angle grinders to process nest lists efficiently, preparing components for welding, machining, or assembly with minimal burrs and reduced secondary finishing.

Competitive advantages include thin-kerf efficiency for faster penetration, an aggressive grain that maintains cutting speed, and bond stability that resists glazing during longer cuts. The fiberglass reinforcement enhances wheel integrity for consistent line tracking. Buyers appreciate how these attributes translate into fewer wheel changes, smoother cut faces, and predictable performance across batches. Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. leverages years of application know-how to balance cut rate and life, offering a Carbon Steel Cutting Disc portfolio that aligns with the productivity targets of fabrication shops, EPC contractors, and maintenance teams alike.

Cost, Maintenance & User Experience

Total cost of ownership for a Carbon Steel Cutting Disc hinges on cost-per-cut, not just unit price. A well-balanced 230mm x 2.0mm disc can reduce operator time, limit changeovers, and lower scrap from overheating or wanding, all of which improve ROI. For B2B decision-makers, predictable consumption rates simplify purchasing and inventory planning, while consistent wheel hardness and density support stable takt times on the production floor. Many users report steady cutting speed and reliable wear patterns that help standardize job costing.

Best practices extend wheel life and safeguard operators: store discs flat in a dry environment, follow FIFO inventory rotation, perform a quick visual check before mounting, and ensure proper flanges and guards are used. Operate within the tool’s rated RPM and avoid side pressure, as cut-off wheels are designed for straight cuts only. In the Abrasive and grinding tools sector, feedback consistently emphasizes how Grassland’s Carbon Steel Cutting Disc from Hebei Double Goats balances fast cutting with control—helping teams cut more parts per shift while maintaining quality and safety discipline.

Sustainability & Market Trends in industrial supplies

Market demand favors high-efficiency, thin-kerf cutting discs that reduce rework and material waste. Across industrial supplies, buyers are aligning procurement with safety and environmental goals—seeking consumables that support clean cuts, consistent process control, and reduced energy per cut. As fabrication, infrastructure, and heavy industry grow, standardized, repeatable performance is a priority, enabling shops to integrate cutting operations into lean workflows and automated cells without quality drift.

Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. approaches sustainability pragmatically—by focusing on process efficiency, stable formulations, and product designs that help customers achieve more cuts per wheel. Extending service life and delivering reliable cut quality lowers overall disc usage and packaging turnover, supporting waste reduction initiatives. The company’s forward-looking R&D and application support ensure its Carbon Steel Cutting Disc range tracks with evolving regulations, operator safety expectations, and the market’s shift toward measurable productivity and ESG outcomes.

Conclusion on Carbon Steel Cutting Disc from Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd.

For metal fabrication, construction, and MRO teams, the Carbon Steel Cutting Disc remains a workhorse consumable that directly influences throughput and finish quality. Grassland’s 230mm solution from Hebei Double Goats combines thin-kerf speed, controlled wear, and dependable batch-to-batch consistency—key advantages for B2B buyers standardizing on one supplier. Partner with a manufacturer known for practicality and reliable delivery.

- Contact us: email: grassland001@china-grassland.com

- Visit our website: https://www.cutoffdiscs.com

Post time:Oct - 29 - 2025