Carbon Steel Cutting Disc is a key solution in the industrial supplies industry, specifically within Abrasive and grinding tools and cutting disc. This article explores how Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Carbon Steel Cutting Disc Overview

- Benefits & Use Cases of Carbon Steel Cutting Disc in cutting disc

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial supplies

- Conclusion on Carbon Steel Cutting Disc from Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd.

Carbon Steel Cutting Disc Overview

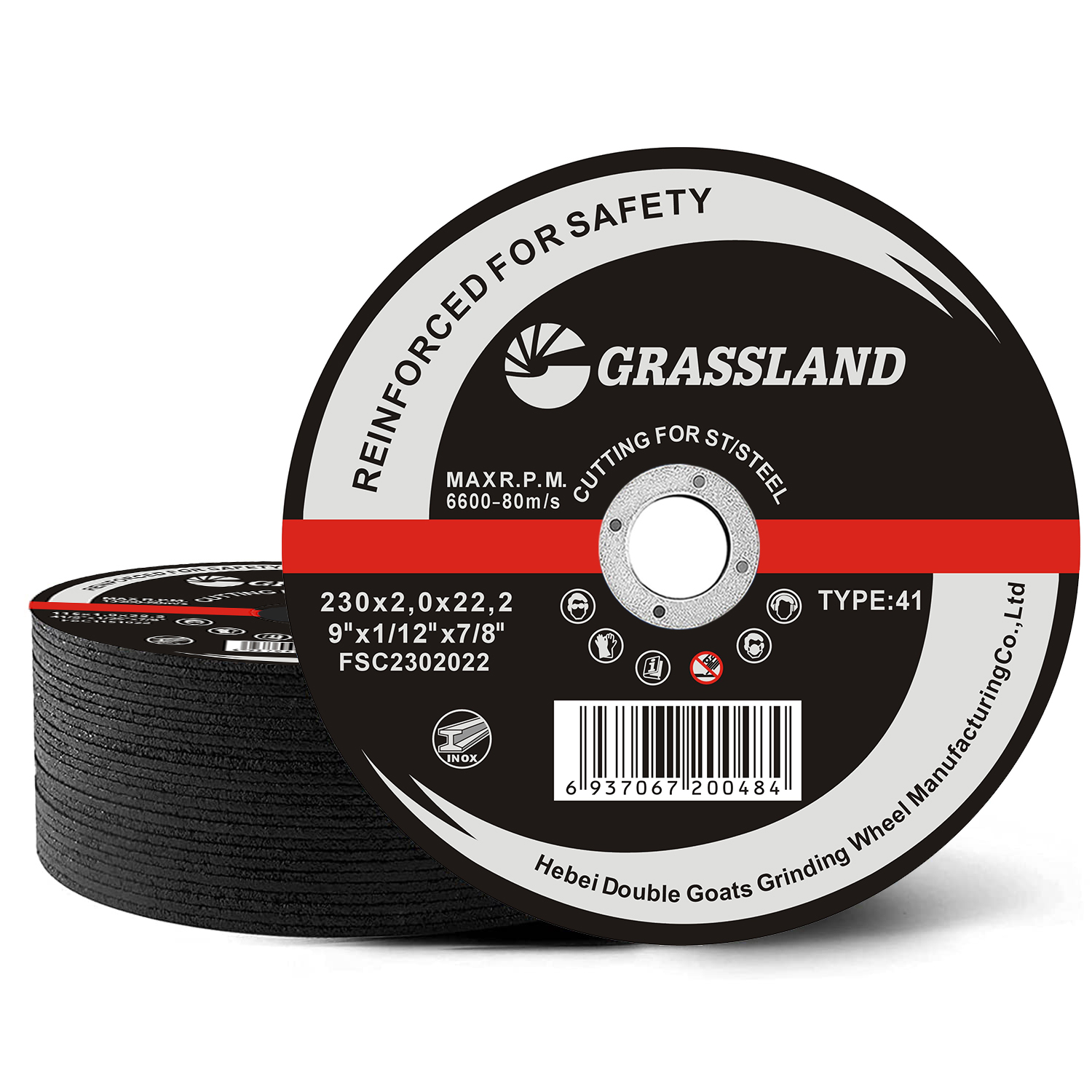

Engineered for fast, clean cutting on ferrous metals, a Carbon Steel Cutting Disc is a thin, resin-bonded abrasive wheel optimized for productivity on carbon steel and mild steel. In the abrasive and grinding tools category, it is a workhorse for fabrication, maintenance, and construction teams who need reliable, repeatable cuts with minimal burr and heat-affected zones. Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. manufactures the Grassland 9-inch (230 mm) x 2.0 mm x 22.23 mm disc to deliver balanced cutting speed and longevity on handheld angle grinders.

Built with sharp aluminum oxide grains and reinforced with fiberglass mesh, the disc provides stability under load and reduced vibration. The 2.0 mm kerf minimizes material loss while maintaining edge strength. Typical specifications include Type 41 (flat) profile, bore 22.23 mm, and operating speeds up to 80 m/s (check the disc label for exact maximum RPM; for 230 mm wheels this is commonly around 6,600 RPM). In field use, metal shops report faster penetration on carbon plate and pipe, with smoother cut faces that reduce downstream grinding. Backed by Hebei Double Goats’ consistent manufacturing and quality controls, this carbon cutting disc supports B2B buyers who prioritize safety, performance, and cost per cut.

Benefits & Use Cases of Carbon Steel Cutting Disc in cutting disc

From structural steel fabrication to MRO, shipbuilding, pipeline work, and rebar processing, the Carbon Steel Cutting Disc is the go-to consumable for straight cuts on beams, tubes, angle iron, and plate. On 9-inch grinders, the 230 x 2.0 x 22.23 format offers an optimal balance of reach and control for yard, shop, and on-site cutting. Many buyers also use this wheel for gate and fence manufacturing, chassis work, and steel furniture production where thin, accurate cuts reduce rework.

- Fast, cool cuts: Sharp A/O grain and a slim 2.0 mm kerf lower cutting resistance and heat build-up for cleaner edges.

- Stability under load: Fiberglass reinforcement helps resist wheel flex and chatter, improving cut accuracy and operator comfort.

- Versatility: Designed for carbon steel and suitable for many general steel applications; variants exist for stainless where low Fe/S/Cl formulas are needed.

- Consistent quality: Hebei Double Goats’ process control delivers predictable wheel hardness and wear, supporting standardized cycle times.

Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. brings multi-decade expertise across bonded abrasives, with a portfolio that supports the full cutting disc lifecycle—from selection and trials to bulk procurement. For B2B decision makers, this means reliable supply, stable performance lots, and technical guidance when optimizing cut speed, finish, and disc life.

Cost, Maintenance & User Experience

Total cost of ownership for a Carbon Steel Cutting Disc is driven by cost per cut and the downstream time saved on deburring or regrinding. The Grassland 230 x 2.0 mm wheel’s thin kerf reduces material waste and heat, which often translates to fewer secondary steps and faster throughput. In practice, buyers report strong life-to-speed balance compared with commodity wheels, enabling fewer wheel changes and more linear feet cut per shift—tangible ROI for fabrication cells and field crews alike.

- Storage & handling: Keep discs dry, avoid temperature extremes, and perform a ring test before mounting. Observe expiration dates.

- Set-up: Use the correct guard and flanges; match wheel size and arbor to the grinder; never exceed the labeled RPM.

- Operation: Cut straight; avoid side loads; let the wheel do the work to extend life and maintain edge quality.

- Feedback: Fabricators value the wheel’s low vibration feel and predictable wear pattern, which supports consistent operator control and safer cutting.

Sustainability & Market Trends in industrial supplies

Across industrial supplies, sustainability and safety are shaping abrasive selection. Thinner cutting discs help reduce energy input and material loss per cut, while smoother edges cut down on additional grinding passes and abrasive consumption. Compliance with recognized safety standards (e.g., EN 12413) and attention to dust control and operator protection is increasingly non-negotiable for enterprise buyers and EPC contractors. Digitalization of inventory, vendor-managed stock, and performance benchmarking are also driving smarter, data-backed purchasing.

Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd. positions its portfolio with these trends in mind—prioritizing stable quality, efficient cutting action, and responsible manufacturing practices. From optimized formulas that aim to cut cleanly to packaging choices that support recyclability, the company aligns product design with EHS expectations and the productivity targets of modern metalworking operations. For B2B decision makers, this means a carbon cutting disc partner that supports safety, sustainability, and performance goals without compromising cost control.

Conclusion on Carbon Steel Cutting Disc from Hebei Double Goats Grinding Wheel Manufacturing Co., Ltd.

A high-quality Carbon Steel Cutting Disc is essential for precise, efficient work across the abrasive and grinding tools segment. Hebei Double Goats’ Grassland 230 x 2.0 x 22.23 wheel delivers fast, stable cuts, reduced burr, and dependable life—key advantages for fabrication shops, contractors, and OEMs. Backed by a reliable manufacturer with strong process control, it helps lower cost per cut while raising throughput and consistency.

- Choose a proven partner for your cutting disc program—value, safety, and performance in one package.

- Contact us: email: grassland001@china-grassland.com

- Visit our website: https://www.cutoffdiscs.com

Post time:Nov - 10 - 2025