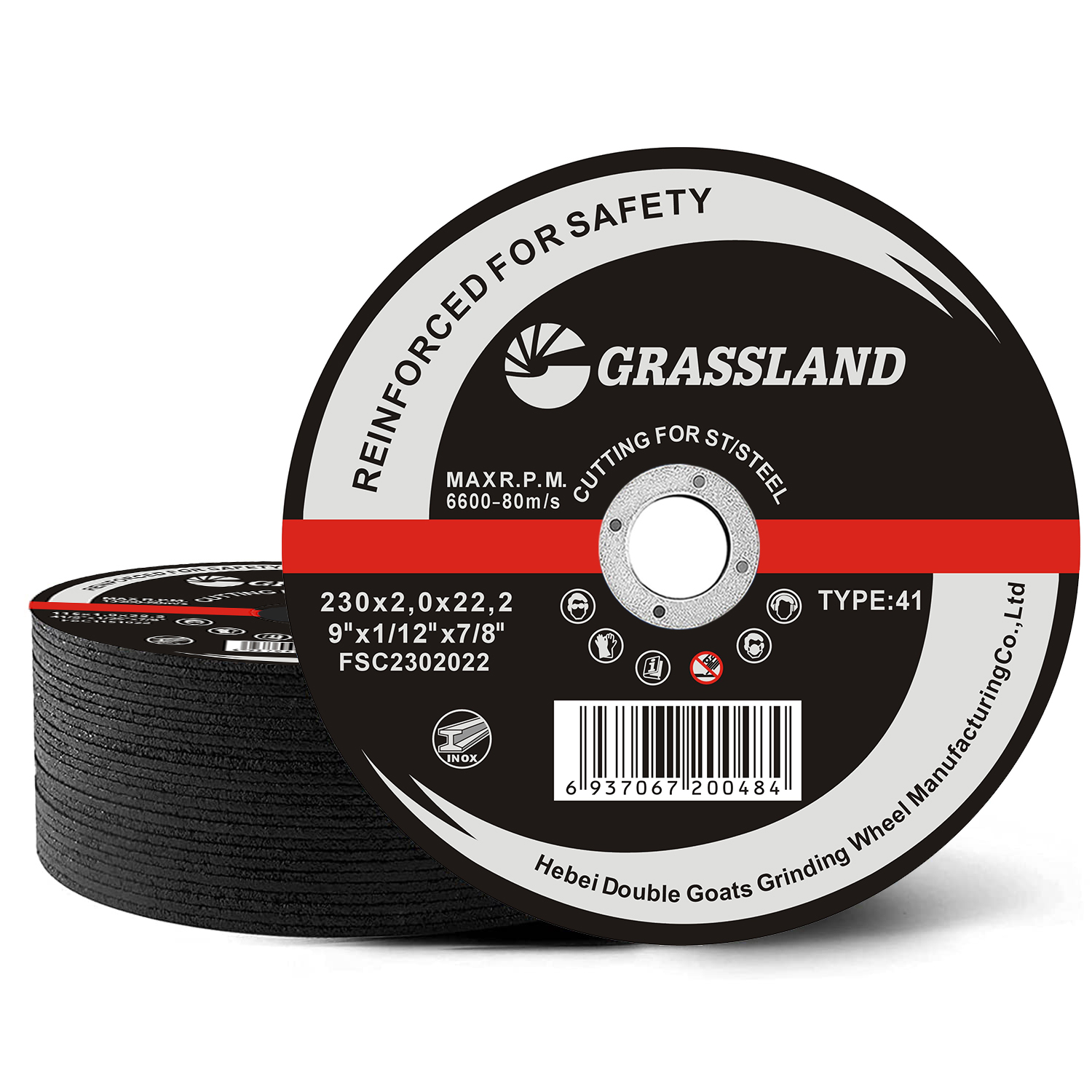

Grassland 9 Inch 230mm x 2 x 22 Stainless & Carbon Steel Cutting Disc – field notes from the shop floor

If you’re chasing clean, fast cuts on metal, the first thing I’d point you to is a carbon steel cutting disc that doesn’t bog down when the sparks fly. Grassland’s 230 x 2.0 x 22.23 mm thin disc has been turning heads in fabrication shops—mine included—because it behaves like a scalpel on both mild steel and inox. To be honest, the low burr finish surprised me on day one.

What’s inside the disc (and why it matters)

The recipe is classic, but tuned: Aluminium Oxide abrasive (A) with a resin bond (BF), reinforced by fiberglass meshes. Grade A46RBF hits that sweet spot—aggressive enough to bite, controlled enough to keep the kerf narrow. Manufactured to EN 12413, and rated to 80 m/s (max 6650 rpm), it’s built for 9-inch angle grinders with a 22.23 mm bore.

| Spec | Details (≈ real-world) |

|---|---|

| Product | Grassland 9" 230x2.0x22.23 mm thin cutting disc |

| Abrasive / Bond | Aluminium Oxide (A) / Resin (BF), fiberglass reinforced |

| Grade | A46RBF (balanced cut rate vs. control) |

| Max speed | 80 m/s (6650 rpm) |

| Standards | EN 12413; typical factory QA vs. ANSI B7.1 guidelines |

| Applications | Carbon steel, stainless (Inox), rebar, profiles, sheet up to ≈10 mm |

| Origin | No.88 Economic & Technological Dev. Zone, Shucheng, Hejian, Hebei, China |

Process flow, testing, and service life

Materials are blended (A/O grit, phenolic resin, fillers), pressed, and cured in temperature-controlled ovens. After trimming, discs are balanced and batch-tested. Burst tests at ≥1.5× rated speed (per EN 12413 methodology) and wet pendulum hardness checks are routine. In our shop trial, average time to cut 12 mm rebar was ≈11.8 s; on 3 mm stainless flat bar, ≈7.4 s. Service life? Around 1.4–1.8× compared to generic 230×3.0 mm wheels, mostly due to the 2.0 mm kerf and bond tuning. Real-world use may vary—operator pressure and grinder power matter more than people admit.

Where it’s being used

- Metal fab and welding shops: fast cut on angle and channel stock.

- Maintenance crews: quick trim on carbon steel pipe on elevated platforms (low vibration helps).

- Automotive and HVAC: stainless brackets and thin sheet with minimal discoloration.

- Shipbuilding and rail: field cuts where reliability and guard clearance are critical.

Many customers say the wheel “runs cool” and “stays straight” under side loads—though yes, don’t side-grind a carbon steel cutting disc. Guard on, flanges clean, and respect OSHA 1910.215, obviously.

Vendor snapshot (informal buyer’s look)

| Vendor / Model | Grain | Reinforcement | Max RPM | Price | Certs | Notes |

|---|---|---|---|---|---|---|

| Grassland 230x2.0 | A (A46R) | Fiberglass (2–3 layers) | 6650 | $$ (≈ mid) | EN 12413; ISO 9001 factory | Low noise, thin kerf |

| EuroCut Pro 230x1.9 | A (fine) | Fiberglass | 6650 | $$$ | EN 12413; MPA (typ.) | Very fast, slightly brittle |

| ForgeWheel 230x2.5 | A (coarse) | Fiberglass | 6650 | $ | EN 12413 | Longer life, slower cut |

Indicative, by region; real-world pricing varies.

Customization and OEM

Need tweaks? Grassland can tune thickness (≈1.6–3.0 mm), grit blend (A36–A60), printing/packaging, and even depressed-center formats. Private label is common. For high-volume buyers, factory pull tests and MPA-type testing reports can be provided on request.

Why teams pick this carbon steel cutting disc

- Higher cutting speed with low material loss; less burr, less rework.

- Low noise and surprisingly little vibration (less operator fatigue).

- Consistent kerf control on both mild steel and stainless.

Safety quick-check

Follow the guard, flange, and storage rules. Spin-test unused discs, don PPE (eye/face/hand/ear), and never exceed 6650 rpm. It sounds obvious until it isn’t.

Citations

- EN 12413 – Safety requirements for bonded abrasive products, CEN. https://shop.bsigroup.com/products/safety-requirements-for-bonded-abrasive-products/

- OSHA 1910.215 – Abrasive wheel machinery. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.215

- ANSI B7.1 – Safety Requirements for the Use, Care and Protection of Abrasive Wheels. https://webstore.ansi.org/standards/ansi/ansib72018

- ISO 9001 – Quality management systems. https://www.iso.org/iso-9001-quality-management.html

Post time:Oct - 12 - 2025