The Evolution and Importance of Cutting Discs in Metalworking

In the realm of metalworking, precision and efficiency are paramount, and cutting discs play a crucial role in achieving these qualities. Over the years, the technology and production of cutting discs have evolved, offering various options tailored to meet different industrial needs. This article delves into the types, applications, and advancements in cutting discs, emphasizing their significance in modern metalworking.

Types of Cutting Discs

Cutting discs, also known as cutting wheels, are thin, disc-shaped tools designed for cutting through various materials, primarily metals. They come in several types, each suited for different applications

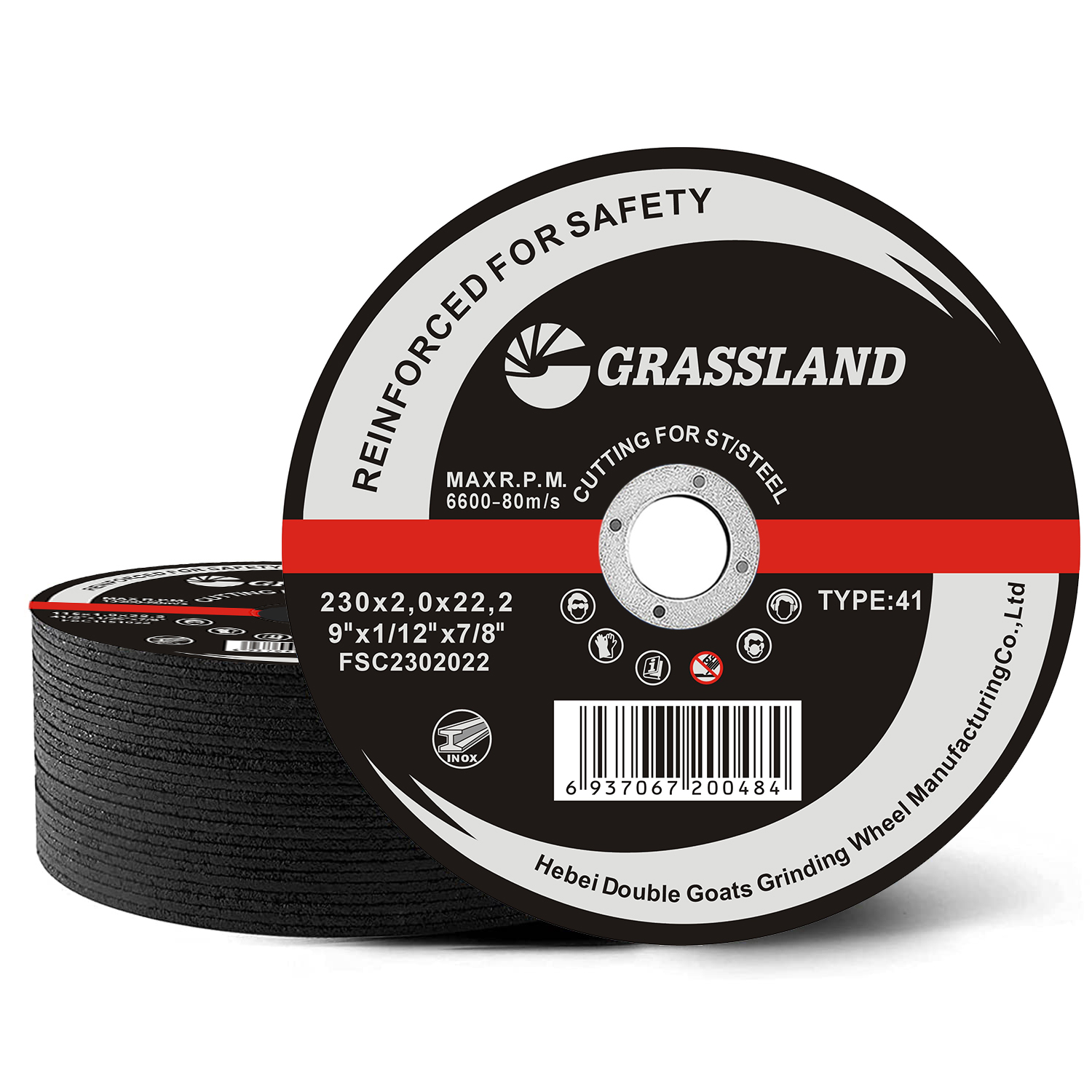

1. Metal Cutting Discs These are specifically designed for cutting ferrous and non-ferrous metals. Generally made from abrasive materials like aluminum oxide or zirconia alumina, these discs offer durability and longevity while maintaining sharpness during use.

2. Diamond Cutting Discs Featuring a diamond-coated edge, these discs are utilized for cutting harder materials such as steel and concrete. The diamonds provide a longer lifespan and a finer cut compared to traditional metal cutting discs.

3. Composite and Specialty Discs These discs cater to specific materials or industries, including plastic, fiberglass, and composites. They often use specialized abrasives to ensure optimal performance on non-metal surfaces.

Applications in Metalworking

The applications of cutting discs in metalworking are vast and varied. Industries ranging from automotive to construction rely on these tools for efficient material processing. Here are some of the key applications

- Fabrication and Manufacturing In manufacturing facilities, cutting discs are indispensable for shaping and sizing metal pieces. They are used in fabricating components for machinery, vehicles, and infrastructure projects, where precision is crucial.

- Welding Preparation Before metal pieces can be welded together, cutting discs are often used to trim excess material or bevel edges. This preparation ensures stronger welds, contributing to the integrity of the final product.

cutting discs metal

- Repair and Maintenance In the maintenance of industrial equipment, cutting discs are frequently employed for tasks that involve cutting out damaged sections or resizing parts to fit new components.

Advances in Technology

The cutting disc industry has seen significant advancements in recent years, driven by the demand for greater efficiency, safety, and performance. Some of the notable innovations include

- Improved Materials The development of tougher and lighter composite materials has led to the production of cutting discs that can withstand higher degrees of stress and heat. This not only enhances durability but also reduces operator fatigue.

- Enhanced Safety Features Many modern cutting discs are designed with safety in mind. Innovations such as vibration-resistant cores and improved bonding agents help to minimize the risk of breakage, thus protecting users from accidents.

- Environmentally Friendly Options There is a growing trend towards sustainability in manufacturing. Many companies are now producing cutting discs that generate less waste and are made from recycled materials, aligning with broader environmental goals.

Choosing the Right Cutting Disc

Selecting the appropriate cutting disc is essential for achieving optimal results. Factors to consider include the type of material being cut, the thickness of the material, and the specific application requirements. It is vital to consult manufacturers’ guidelines and safety recommendations to ensure that the correct disc is chosen for the task at hand.

Conclusion

Cutting discs are indispensable tools in the metalworking industry, offering precision, efficiency, and versatility. Understanding the various types, applications, and advancements of cutting discs allows manufacturers and metalworkers to make informed decisions that enhance productivity and safety. As technology continues to evolve, we can anticipate further innovations that will redefine the capabilities and applications of cutting discs, ensuring they remain vital tools in the ever-evolving landscape of metalworking. Whether you are involved in heavy industry or small-scale projects, the right cutting disc can make all the difference in achieving high-quality results.

Post time:Dec - 05 - 2024