What Are Cutting Discs Made Of?

Cutting discs are essential tools widely used in various industrial applications, including metalworking, construction, and maintenance. These discs enable operators to cut through a wide range of materials, such as metal, stone, and ceramics, with precision and efficiency. The effectiveness and durability of cutting discs depend significantly on their composition. This article will delve into the materials used to manufacture cutting discs, their production processes, and the implications of these materials on performance and safety.

Composition of Cutting Discs

Typically, cutting discs are made from a combination of abrasive materials and binding agents. The most common materials found in cutting discs include

1. Aluminium Oxide One of the most prevalent abrasive materials, aluminium oxide is effective for cutting ferrous metals. It is known for its durability and ability to withstand high temperatures, making it a popular choice for general-purpose cutting discs.

2. Silicon Carbide This material is ideal for cutting hard, brittle materials, such as ceramics, marble, and fiberglass. Silicon carbide cutting discs have a unique crystalline structure that provides a sharp edge, which is crucial for precise cutting.

3. Diamond Diamond cutting discs are designed for specialized applications. They are particularly effective for cutting extremely hard materials like granite, concrete, and other masonry. The high hardness and sharpness of diamond particles allow for clean and efficient cuts, making them a preferred choice in construction and demolition industries.

4. Resin Bond To hold the abrasive particles together, cutting discs use resin bonds. These resins can withstand high temperatures and provide flexibility to the disc. The inclusion of other materials, such as rubber or phenolic resins, can enhance the disc's strength and durability.

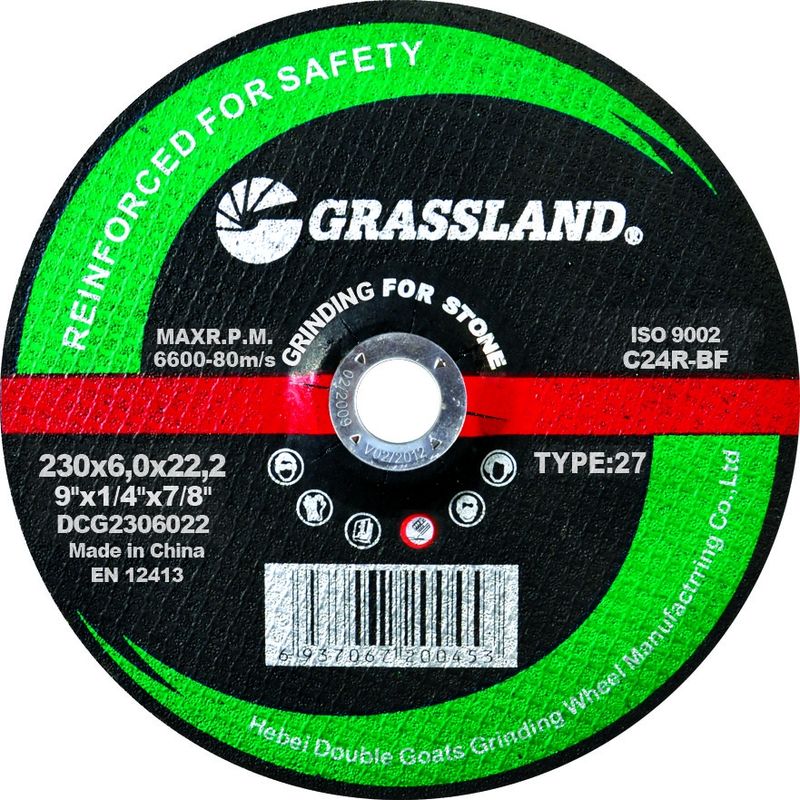

5. Reinforcement Fibers To improve safety and durability, cutting discs are often reinforced with fiber materials like fiberglass. This reinforcement helps prevent the disc from shattering during use, which can pose a significant safety risk to operators.

Production Process

de que estan hechos los discos de corte

The manufacturing process of cutting discs involves several critical steps to ensure the quality and performance of the final product

. The general process includes1. Mixing The first step involves mixing the abrasive materials with bonding agents and other additives. The mixture is uniformly blended to achieve an even distribution of materials.

2. Molding The blended mixture is then placed into molds. The shaping process may vary depending on the desired final shape and size of the cutting disc. The molds can produce various disc diameters and thicknesses to accommodate different applications.

3. Pressing Once the mixture is in the molds, they are subjected to high pressure. This step compacts the materials, enabling them to bond effectively during the curing stage.

4. Curing The pressed discs are then cured in ovens at high temperatures. This process allows the resin to harden and bond the abrasive materials securely, thus forming a solid disc.

5. Grinding and Finishing After curing, the discs undergo grinding to achieve the desired dimensions and surface finish. Quality control measures are essential during this stage to ensure that each disc meets industry standards.

Performance and Safety Implications

The choice of materials in cutting discs has a direct impact on their performance and safety. For instance, using higher-quality abrasives can lead to faster cutting speeds and longer lifespan, which is beneficial for both efficiency and cost-effectiveness. Safety is another crucial consideration; poorly made or unsuitable discs may shatter under stress, causing injuries. Therefore, using discs that follow strict safety protocols and specifications is vital for operators.

Conclusion

In summary, cutting discs are complex tools made from a variety of materials, primarily abrasive compounds and bonding agents. Understanding the composition and production processes of cutting discs is essential for selecting the right disc for a specific application. As industries continue to advance, the development of cutting disc technology will play a crucial role in improving efficiency, safety, and usability in various applications. Whether you are a professional in the field or a DIY enthusiast, knowing what cutting discs are made of can significantly enhance your cutting experience and outcomes.

Post time:Dec - 05 - 2024