Understanding Metal Cutting Discs A Comprehensive Guide

Metal cutting discs, commonly referred to as abrasive discs, are essential tools in the metalworking industry. They are specifically designed to cut through various types of metal with precision and efficiency. This article aims to provide an in-depth understanding of these vital tools, including their types, applications, safety considerations, and best practices for use.

What Are Metal Cutting Discs?

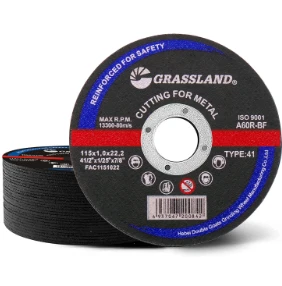

Metal cutting discs are thin, flat wheels made of abrasive materials that are mounted on grinding machines or angle grinders. They are designed to remove material from the workpiece, creating clean cuts in various metals such as steel, aluminum, and stainless steel. The discs can vary in size, thickness, and material composition, making them versatile for different machining applications.

Types of Metal Cutting Discs

There are several types of metal cutting discs available on the market, each tailored for specific applications

1. Abrasive Discs Typically made from aluminum oxide or zirconia, these are the most common type of metal cutting discs. They are ideal for cutting various metals but may not last as long on harder materials.

2. Diamond Cutting Discs These discs are embedded with diamond particles, making them extremely durable. They are used primarily for cutting hard materials, such as stainless steel and reinforced concrete.

3. Ceramic Discs Known for their longevity and cutting power, ceramic discs are used in high-performance applications. They are particularly suited for processing hard metals and offer a cooler cutting action.

4. Thin Cutting Discs These provide faster cutting speeds and less material removal, making them suitable for precision cuts, especially in sheet metal and thin plates.

5. Thick Cutting Discs Generally more robust, these discs are used for heavier cutting applications and can handle tougher materials.

Applications of Metal Cutting Discs

Metal cutting discs are versatile tools that find applications across various industries, including

- Construction For cutting rebar, metal sheets, and structural components. - Manufacturing Ideal for processing raw materials during the fabrication of products. - Automotive Used to cut and shape metal parts in vehicle manufacturing and repair. - Aerospace For precision cutting of high-strength alloys and specialized components.

Safety Considerations

disco de corte metal

When working with metal cutting discs, safety should always be a priority. Here are some key safety tips

1. Personal Protective Equipment (PPE) Always wear safety glasses, gloves, and a dust mask to protect against flying debris and inhalation of harmful particles.

2. Check Equipment Regularly Inspect your angle grinder or cutting machine for any signs of wear and damage before use. Ensure the disc is properly mounted and securely attached.

3. Avoid Overheating Excessive heat can cause the disc to wear out faster or even break. Use a steady, moderate speed and avoid forcing the cut.

4. Maintain a Clean Work Area A cluttered workspace can increase the risk of accidents. Clear away any unnecessary items before beginning your work.

5. Proper Cutting Techniques Maintain a firm grip on the cutting tool and use steady movements for better control. Always cut in the recommended direction (usually from the side).

Best Practices for Use

To maximize the effectiveness and lifespan of metal cutting discs, consider the following best practices

- Choose the Right Disc Match the disc type with the material you are cutting. This will ensure optimal performance and reduce the risk of disc failure.

- Use Fresh Discs Worn discs can cause inaccurate cuts and compromise safety. Replace them as soon as you notice signs of wear.

- Store Properly Store cutting discs in a cool, dry place to prevent moisture and degradation.

- Follow Manufacturer Guidelines Always adhere to the manufacturer's instructions regarding the speed rating, use cases, and safety measures for the specific disc you are using.

Conclusion

Metal cutting discs are indispensable tools in various industrial applications, from construction to automotive manufacturing. Understanding the different types, applications, and safety measures associated with these discs will enhance both the efficiency of your work and your safety. By following best practices and choosing the right cutting disc for the job, you can achieve precise results while minimizing risks. Whether you are a seasoned professional or a DIY enthusiast, metal cutting discs are essential for your toolkit.

Post time:Dec - 09 - 2024