The Disc of Cutting for Aluminum A Comprehensive Guide

Aluminum is one of the most versatile and widely used metals in various industries, including aerospace, automotive, and construction. Its lightweight and corrosion-resistant properties make it an ideal choice for many applications. However, working with aluminum presents specific challenges, particularly when it comes to cutting. The right tools and techniques are crucial for ensuring clean, precise cuts without damaging the material. One essential tool for this job is the cutting disc specifically designed for aluminum.

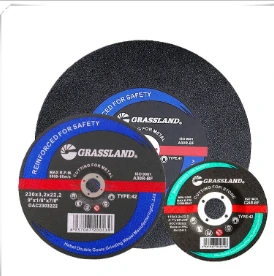

Understanding Cutting Discs

Cutting discs, or blades, are critical tools used to slice through different materials. These discs are typically mounted on power tools, such as angle grinders and circular saws, and are essential for achieving efficient and clean cuts. When it comes to aluminum, using the appropriate cutting disc is vital. Regular steel cutting discs can lead to excessive heat generation, edge dulling, and a poor quality cut, resulting in rough edges and possible deformation of the aluminum.

Types of Cutting Discs for Aluminum

There are various types of cutting discs designed specifically for aluminum, each with unique properties and purposes

1. Aluminum Oxide Discs These discs utilize aluminum oxide grains, which provide excellent cutting ability without causing excessive heat. They are well-suited for both soft and hard alloys of aluminum.

2. Ceramic Discs While typically more expensive, ceramic discs deliver high performance in cutting aluminum. Their durability allows for a longer lifespan compared to other types.

3. Diamond Bladed Discs These are used for precision cutting and are particularly useful for thicker aluminum materials. The diamond coating reduces heat buildup, ensuring cleaner cuts and prolonging the disc's life.

4. Metal Cutting Discs Though not exclusively for aluminum, metal cutting discs made with a specific design for non-ferrous metals can also be used effectively on aluminum without harming the material.

Choosing the Right Cutting Disc

Selecting the right cutting disc for aluminum depends on several factors

- Material Thickness Thicker materials may require specialized discs that cater to heavy-duty cutting

.disco de corte para aluminio

- Alloy Type Different aluminum alloys may react differently to cutting, so selecting a disc compatible with the specific alloy is essential.

- Cut Quality Required If precision is critical, a higher-quality disc may be worth the investment.

- Speed and Power of the Tool Understanding your cutting tool's capabilities can help in selecting the right disc. Using a disc incompatible with the tool can lead to safety hazards and inefficient cutting.

Best Practices for Cutting Aluminum

When using cutting discs on aluminum, following best practices is vital to achieve efficient results and maintain safety

1. Use Proper RPM Settings Always check the RPM rating of the disc and ensure it matches the specifications of your cutting tool. Running a disc at excessive speeds can lead to breakage and personal injury.

2. Keep the Material Secure Securing the aluminum workpiece prevents movement during cutting, ensuring a cleaner cut and reducing the risk of accidents.

3. Use Lubrication Applying cutting oil or lubricant can help dissipate heat, prolonging the disc's life and improving cut quality.

4. Wear Protective Gear Always ensure that appropriate safety equipment, such as goggles and gloves, is worn during the cutting process to protect against debris and sharp edges.

5. Inspect the Disc Regularly Examine the cutting disc for wear or damage before each use. A damaged disc can shatter upon use, posing a serious safety risk.

Conclusion

Using the right cutting disc for aluminum is crucial for anyone involved in metalworking, fabrication, or similar fields. By understanding the various types of discs, choosing the appropriate one based on material characteristics, and following best practices during cutting, it is possible to achieve high-quality results that meet project requirements. With advancements in cutting technology, professionals can complete their work more efficiently and safely than ever before. Therefore, the disc of cutting for aluminum is not just a tool; it's a gateway to precision and high-quality craftsmanship in metalwork.

Post time:Dec - 16 - 2024