The Importance and Uses of Polishing Cut-off Discs

In various industries and applications, the necessity for precision and finish cannot be overstated. Whether it is in metalworking, woodworking, or even automotive repairs, having the proper tools at your disposal ensures not just efficiency but also high-quality results. Among these essential tools are polishing cut-off discs, which are pivotal in getting the job done right.

What Are Polishing Cut-off Discs?

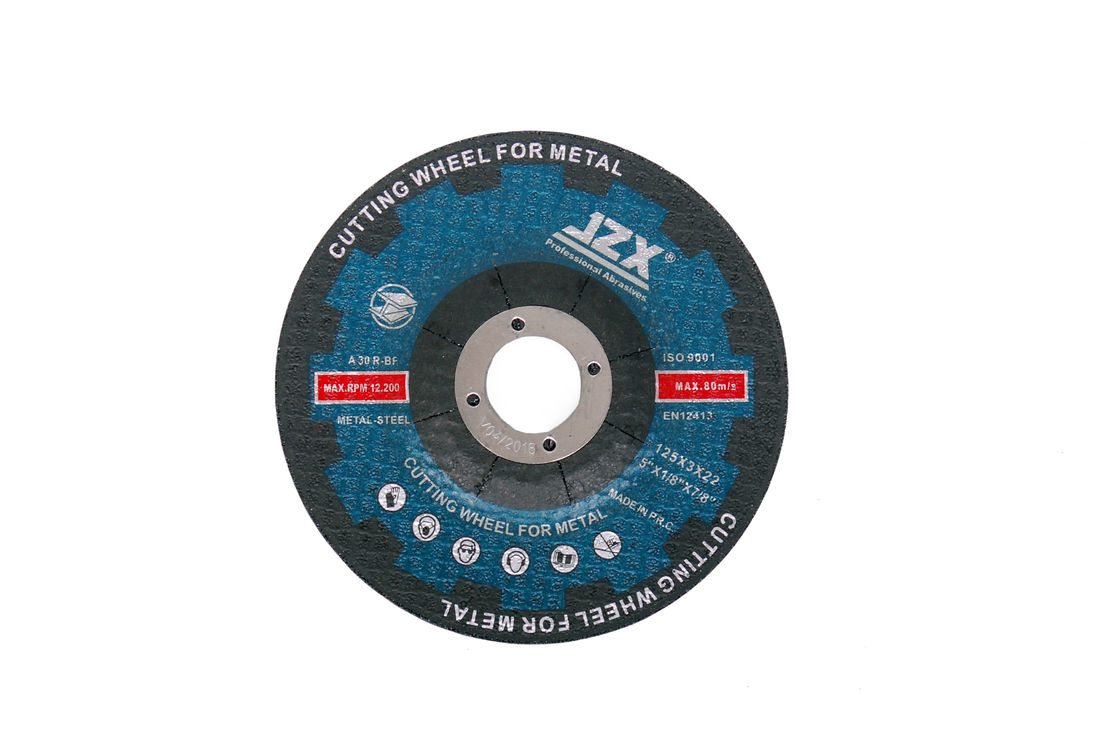

Polishing cut-off discs are specifically designed tools used to cut through and polish materials. They vary in size and composition, tailored to handle different types of materials such as metals, plastics, and wood. These discs are typically made from a combination of abrasive ingredients that include aluminum oxide, silicon carbide, or diamond, thus enhancing their performance in cutting and polishing tasks.

Applications

One of the primary applications of polishing cut-off discs is in the metalworking industry. When fabricating components, it is crucial to achieve a smooth finish on metallic surfaces. Using a cut-off disc allows for quick removal of excess material, followed by polishing to achieve that perfect sheen. This is especially important in industries where aesthetics are critical, such as automotive manufacturing or appliance production.

In woodworking, polishing cut-off discs are an invaluable asset. They enable woodworkers to not only cut wood with precision but also give it a polished finish that highlights the natural beauty of the grain. The ability to transition seamlessly from cutting to polishing helps woodworkers save time and maintain consistency in their projects.

Advantages of Using Polishing Cut-off Discs

1. Versatility One of the standout features of polishing cut-off discs is their versatility. They can be used across different materials and industries, which makes them an essential tool for professionals and hobbyists alike.

2. Efficiency Using these discs significantly reduces the amount of time required to complete a project. Their cutting capability allows for quick material removal, and as a result, they can expedite the workflow in ways traditional sanding or cutting methods may not.

disco de corte pulidora

3. Quality Finish The specialized abrasives in polishing cut-off discs ensure that the finish is smooth and even. This quality is crucial, especially in industries where even minor imperfections can lead to product rejection or failure.

4. Ease of Use Most polishing cut-off discs can be used with standard rotary tools or grinders, making them accessible for various users. Whether you are a seasoned professional or a DIY enthusiast, you can find the right kind of disc for your tools.

Selecting the Right Polishing Cut-off Disc

Choosing the appropriate polishing cut-off disc for your specific task is essential. Factors to consider include the material you will be working with, the thickness of the material, and the required finish. For instance, when dealing with harder materials such as stainless steel, diamond-coated discs may be your best option for durability and performance.

Moreover, it's vital to pay attention to the RPM (revolutions per minute) rating of your tool versus the disc's specifications. Using a disc rated for higher speeds than your tool can operate could lead to unsafe conditions, including disc breakage.

Safety Precautions

While polishing cut-off discs are incredibly useful, safety must always be your top priority. Users should wear appropriate personal protective equipment including gloves, goggles, and a dust mask to minimize exposure to harmful particles. Also, it’s crucial to perform regular maintenance checks on tools to ensure that everything is functioning correctly and safely.

Conclusion

Polishing cut-off discs hold significant importance across various fields from metalworking to woodworking and beyond. Their ability to provide efficient cutting, followed by a polished finish, makes them an indispensable part of any toolkit. As industries continue to evolve and demand higher quality products, the reliance on advanced tools such as polishing cut-off discs will only increase. Thus, recognizing their advantages and using them safely is essential for achieving the best outcomes in your projects.

Post time:Dec - 07 - 2024