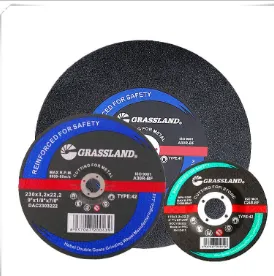

When precision and performance matter, thin metal cutting discs for angle grinders are indispensable tools for metalworking. These 115mm thin metal cutting discs excel in creating clean, accurate cuts with minimal material waste. Ideal for professionals and DIY enthusiasts alike, thin metal cutting discs bring efficiency and precision to every project. Here’s what makes these discs so valuable, along with essential tips for maximizing their use and longevity.

Thin Metal Cutting Discs for Angle Grinder: Unmatched Efficiency

The thin metal cutting disc for angle grinders is engineered to achieve swift, efficient cuts on various types of metal. Its slim design allows for smoother, faster cutting compared to standard discs, which can be especially beneficial for detailed or intricate work. With less material removed per cut, thin metal discs reduce cutting resistance, ensuring the angle grinder operates smoothly and efficiently. This feature makes it the go-to choice for tasks requiring high precision and minimal burrs.

115mm Thin Metal Cutting Disc: Perfect for Precision

The 115mm thin metal cutting disc is an ideal size for detailed metalwork, combining the right diameter with a slim profile to maximize control and accuracy. This size is versatile, fitting most standard angle grinders and providing ample reach for detailed work on metals such as steel, aluminum, and copper. Its balanced construction enhances maneuverability, making it perfect for cutting applications where precision is essential. The 115mm disc’s size ensures it can handle both smaller DIY projects and professional-grade tasks with equal efficiency.

Cutting Performance Analysis of Thin Metal Discs

When it comes to cutting performance analysis, thin metal cutting discs outperform thicker alternatives by delivering quicker cuts with reduced effort. The thin profile generates less friction and heat, which minimizes wear on the disc and helps maintain the integrity of the cut metal. These discs create a narrow cut path, resulting in less wasted material and preserving more of the original metal structure. This cutting efficiency translates into cost savings, as the disc’s longevity and reduced energy use lower operational expenses.

Precautions and Maintenance for Angle Grinder Discs

Proper precautions and maintenance are vital to extending the life of thin metal cutting discs for angle grinders. Always use the correct size and speed setting on your angle grinder to prevent disc damage and ensure safety. Regularly inspect the disc for any signs of wear or damage, as using compromised discs can pose safety hazards. When not in use, store discs in a dry, cool place to avoid exposure to moisture, which can weaken their structural integrity. Following these maintenance tips will keep your discs in optimal condition, ensuring both safety and performance on the job.

Selecting High-Quality Thin Metal Discs for Superior Results

Choosing high-quality thin metal cutting discs for angle grinders is essential for consistent, professional results. Look for discs from trusted brands that prioritize durability and performance. High-grade discs are designed to last longer, cut smoother, and maintain a consistent thickness throughout use, reducing the need for frequent replacements. Investing in quality ensures not only reliable performance but also enhanced safety and efficiency, making thin metal cutting discs an excellent choice for metalworking projects.

With their precise design, reliable cutting performance, and ease of use, thin metal cutting discs for angle grinders—especially 115mm thin metal cutting discs—are indispensable tools in the metalworking world. Following proper maintenance and selecting high-quality discs will help maximize their performance, ensuring clean, accurate cuts and extending the life of both the disc and the angle grinder. Whether for small DIY jobs or large-scale projects, these thin metal cutting discs deliver the precision and efficiency needed to achieve excellent results.

Post time:Nov - 19 - 2024