In high-performance metalworking environments, precision is non-negotiable. When it comes to cutting aluminum—a material prized for its lightweight strength and versatility—using the right tools is essential. One tool that has proven indispensable is the aluminum cut-off wheel. These wheels are engineered not just for slicing through aluminum cleanly, but also for minimizing burrs, overheating, and deformation, making them a superior option for industrial and workshop applications alike.

Performance Improves When Aluminum Cut Off Wheels Meet the Right RPM

Choosing aluminum cut off wheels for your workshop goes beyond basic compatibility. These wheels must be matched to the appropriate rotational speed to avoid clogging or glazing, common challenges when working with softer metals like aluminum. While general-purpose wheels may overheat or load quickly, dedicated aluminum cut-off wheels use a special abrasive matrix designed to clear debris efficiently, maintain a cool cut, and extend the wheel’s operational life.

Precision Engineering Demands the Right Cut Off Wheel for Aluminum Alloys

One of the most overlooked issues in metal fabrication is material-specific tooling. The cut off wheel for aluminum stands apart due to its unique bond composition and grain structure, which are designed specifically to reduce chip welding and improve cutting accuracy. Whether you're working on automotive components, aircraft parts, or architectural fixtures, aluminum demands a precise and clean approach. Choosing wheels formulated for non-ferrous metals prevents surface burns and improves operator safety.

Workflows Benefit from High-Quality Cut Off Wheels for Aluminum Efficiency

Efficient workflow in metal fabrication requires tools that can keep up with demand. By selecting high-performance cut off wheels for aluminum, operators reduce the need for frequent wheel changes, minimize downtime, and avoid excessive finishing work. Unlike wheels designed for steel or iron, aluminum-specific wheels typically feature softer bonding agents, which provide smoother finishes and reduce resistance during the cut. This translates to faster jobs and higher-quality results.

Avoid Damage with Proper Cut Off Wheel Aluminum Cutting Techniques

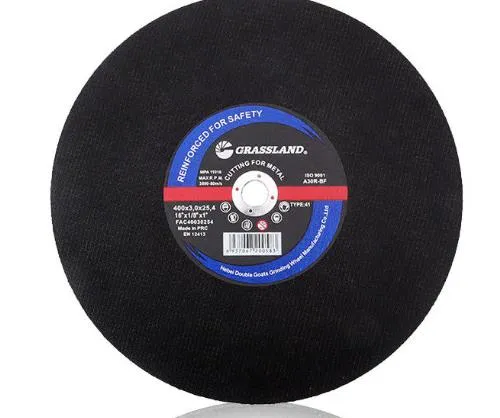

Using a cut off wheel aluminum rated product ensures better results, but cutting technique matters just as much. Apply steady, moderate pressure and avoid forcing the wheel into the material—this helps prevent heat buildup and loading. Some modern cut-off wheels are also reinforced for side pressure resistance, reducing the risk of shattering or wobble. Always ensure your cutting station has proper ventilation and PPE protocols in place, especially when working in high-volume settings.

Choose the Right Cut-Off Wheel for Aluminum to Reduce Wear and Tear

Not all abrasives are created equal. A well-engineered cut-off wheel for aluminum dramatically reduces premature wear not only of the wheel itself, but also of your tools and machinery. High-quality options often include specialized additives or grain coatings that reduce friction and heat generation, which helps preserve motor life on angle grinders or stationary cut-off saws. Over time, this contributes to lower maintenance costs and fewer repairs.

Which Machines Work Best with Aluminum Cut-Off Wheels?

Aluminum cut-off wheels can be used with angle grinders, chop saws, and stationary cutting tools. Always verify that your wheel is the right diameter and arbor size for your machine. Many wheels come with adaptors or are reinforced for compatibility with higher torque devices.

Can I Use a Steel Cut-Off Wheel on Aluminum?

Technically yes, but it’s not recommended. Steel wheels tend to load up with aluminum residue, increasing the risk of glazing and overheating. For best performance and safety, always use a wheel specifically formulated for aluminum cutting.

What Safety Gear Should Be Used When Cutting Aluminum?

At a minimum, wear safety glasses, gloves, hearing protection, and a dust mask. For larger operations or continuous cutting, consider a full-face shield and a dust extraction system to handle aluminum particles effectively.

Cut Off Wheels for Aluminum FAQs

Q: Why are aluminum cut off wheels different from general-purpose wheels?

A: They use softer bonding agents and special grain formulas to prevent clogging and overheating, which are common problems when cutting softer metals like aluminum.

Q: What’s the lifespan of a cut off wheel for aluminum compared to a steel wheel?

A: Although aluminum wheels may wear slightly faster, they offer superior cut quality and reduce the need for post-cut finishing, which saves time and labor.

Q: How can I maintain the performance of my cut off wheels for aluminum?

A: Store them in a dry, cool place, and inspect for cracks or damage before use. Clean your work area regularly to prevent residue buildup, which can affect cutting efficiency.

Q: Can cut off wheel aluminum types be used for curved or angled cuts?

A: While primarily designed for straight cuts, some thin-profile wheels allow for gentle angle cuts if used with precision. However, always refer to the manufacturer’s guidelines.

Q: Are cut-off wheels for aluminum suitable for both professional and DIY use?

A: Absolutely. They are ideal for professionals in automotive, construction, and fabrication, as well as DIY users looking for clean, efficient cuts on aluminum sheets or bars.

Post time:Aug - 20 - 2025