Understanding Grinder Metal Cutting Discs A Comprehensive Guide

In the world of metalworking, one of the most essential tools is the angle grinder, known for its versatility and efficiency in various applications, particularly cutting metal. At the heart of this tool’s effectiveness lies the metal cutting disc. Choosing the right disc is crucial for achieving optimal results while ensuring safety and durability.

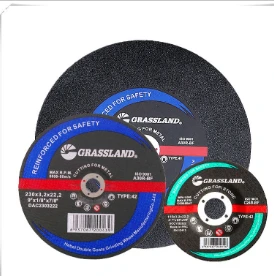

What is a Grinder Metal Cutting Disc?

A grinder metal cutting disc, often referred to as a cutting wheel, is a circular flat tool that is designed to cut through metal materials. These discs are typically made from abrasive materials such as aluminum oxide, zirconia, or silicon carbide, which are bonded together to form a solid disc. The discs are engineered to withstand high rotational speeds and are available in various thicknesses, sizes, and grit levels, making them suitable for a wide range of cutting tasks.

Types of Metal Cutting Discs

1. Abrasive Discs These are the most common types used for cutting metal. They come in different grit sizes, allowing for both coarse and fine cuts depending on the application. Rougher grits are ideal for fast material removal, while finer grits provide smoother finishes.

2. Diamond Blades For cutting harder metals or materials, such as stainless steel or cast iron, diamond blades are preferred. They feature a diamond grit edge that allows for more precise and cleaner cuts, reducing the risk of chipping.

3. Specialty Discs There are discs specifically designed for particular tasks, such as cutting thin sheet metal, rebar, or even masonry materials. These specialized discs can enhance productivity and improve outcomes by offering tailored solutions.

Choosing the Right Metal Cutting Disc

When selecting a metal cutting disc, several factors must be considered

- Material Type The material being cut plays a significant role in the choice of the disc

. Softer metals like aluminum may require different discs than harder metals like steel or titanium.grinder metal cutting disc

- Thickness of the Material Thicker materials usually need thicker discs for improved durability and cutting effectiveness.

- Disc Size The size of the cutting disc must match the specifications of the angle grinder. Using a disc that is too large or too small can lead to safety hazards and ineffective cutting.

- Grit Size Coarse grits remove material quickly but may leave a rough finish, while finer grits provide smoother finishes but require more time.

Safety Precautions

Using a metal cutting disc involves inherent risks, and adhering to safety precautions is paramount

- Personal Protective Equipment (PPE) Always wear safety goggles, gloves, and a dust mask to protect against flying debris and dust.

- Correct Speed and Pressure Ensure the grinder is running at the appropriate speed and apply consistent but not excessive pressure to avoid disc breakage.

- Secure Workpieces Always secure the metal being cut with clamps or a vice to prevent movement during cutting.

- Inspect Discs Regularly check cutting discs for wear or damage before use. Never use a damaged disc, as it can shatter and cause serious injury.

Conclusion

Grinder metal cutting discs are vital tools that enhance the efficiency of metal cutting processes in various industries, including manufacturing, construction, and automotive repair. By understanding the different types of discs, how to choose the right one, and adhering to appropriate safety measures, users can maximize their cutting performance while ensuring their safety and the longevity of their equipment. Whether you are an experienced metalworker or a novice hobbyist, investing time in selecting the right tools will invariably result in better outcomes and a more enjoyable working experience.

Post time:Dec - 13 - 2024