Grinding wheels play an indispensable role in the manufacturing industry

, particularly in metalworking. As China emerges at the forefront of industrial manufacturing, the quality and innovation associated with Chinese grinding wheels have gained significant attention globally. With extensive experience in the field, this article aims to provide a comprehensive guide to understanding the offerings and advantages of grinding wheels from China, establishing a testament to both expertise and trustworthiness.

China's vast industrial landscape features a myriad of manufacturers specializing in grinding wheel production. These manufacturers use advanced technologies and stringent quality control measures, resulting in products that not only meet but often exceed international standards. Professionals who have regularly relied on Chinese grinding wheels often commend their durability and cost-effectiveness, especially when compared to products from Western counterparts.

For anyone in the market seeking to understand the intricacies of grinding wheels made in China, it is crucial to focus on their composition and application. Typically, these wheels are crafted from high-quality abrasives like aluminum oxide, silicon carbide, and more specialized materials like boron nitride. Each type of abrasive is suitable for different materials and applications, lending a layer of customization to the manufacturing process.

In particular, aluminum oxide wheels are praised for their versatility and are widely used across industries for grinding carbon steels, alloy steels, wrought iron, and more. Meanwhile, silicon carbide wheels offer superiority in grinding harder materials such as cast iron, non-ferrous metals, and rubber. The introduction of advanced abrasives like cubic boron nitride significantly benefits high-precision projects, emphasizing the technological prowess inherent in Chinese manufacturing.

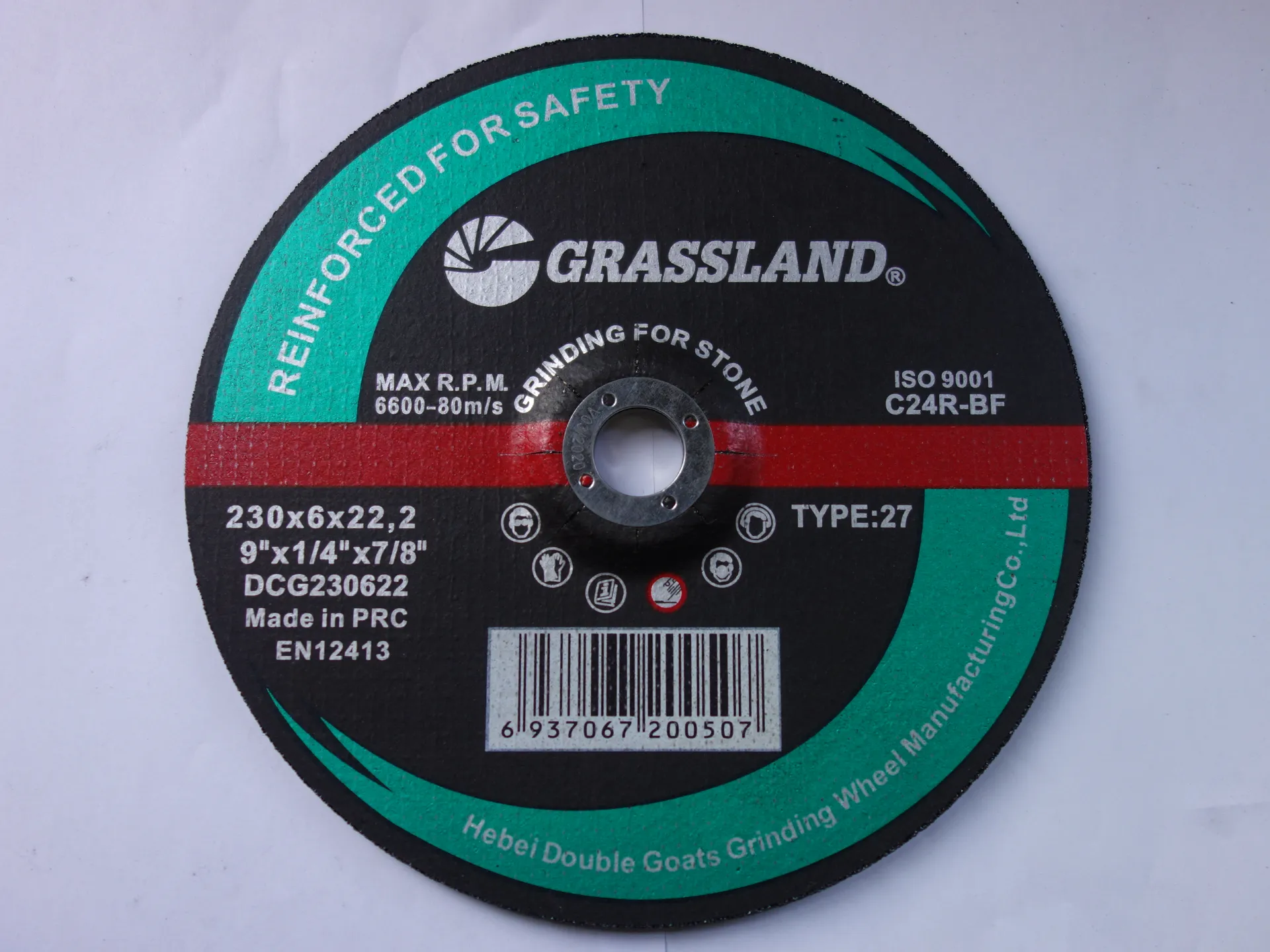

grinding wheels china

The expertise of Chinese manufacturers in producing these grinding wheels is backed by their investment in research and development. Many factories operate dedicated R&D departments focused on innovating their product lines to meet the ever-evolving needs of global industries. This commitment to innovation ensures that users have access to the latest advancements, such as enhanced heat dissipation, improved cutting efficiency, and longer wheel life.

The authority of Chinese grinding wheel products is further substantiated by their widespread certification and compliance with international quality standards. ISO 9001, CE, and SGS certifications are commonly associated with Chinese manufacturers, providing reassurance to international buyers about the reliability and performance of these products. Furthermore, many Chinese firms adhere to strict environmental regulations, emphasizing sustainable production practices.

Trustworthiness in the industry is often measured through customer testimonials and long-standing partnerships with international companies. Chinese manufacturers frequently maintain robust after-sales support and customer service networks, ensuring that global clients experience seamless transactions and support. This dedication to customer satisfaction not only fosters trust but also establishes enduring business relationships.

In conclusion, China's grinding wheel industry exemplifies a harmonious blend of experience, expertise, authority, and trustworthiness. By emphasizing quality control, innovation, and customer satisfaction, Chinese grinding wheel manufacturers consistently deliver products that meet the demands of diverse industries worldwide. For professionals seeking reliable and efficient grinding solutions, the range and capability of Chinese grinding wheels offer a compelling argument worthy of consideration. With a legacy rooted in precision and adaptability, these products stand as a testament to China's commitment to industrial excellence.

Post time:Jan - 06 - 2025