Achieving clean and precise cuts in masonry materials is essential for professional and durable results. Whether you are working on a decorative piece or a structural project, the choice and use of your grinder masonry disc play a crucial role.

Selecting the Right Grinder Masonry Disc

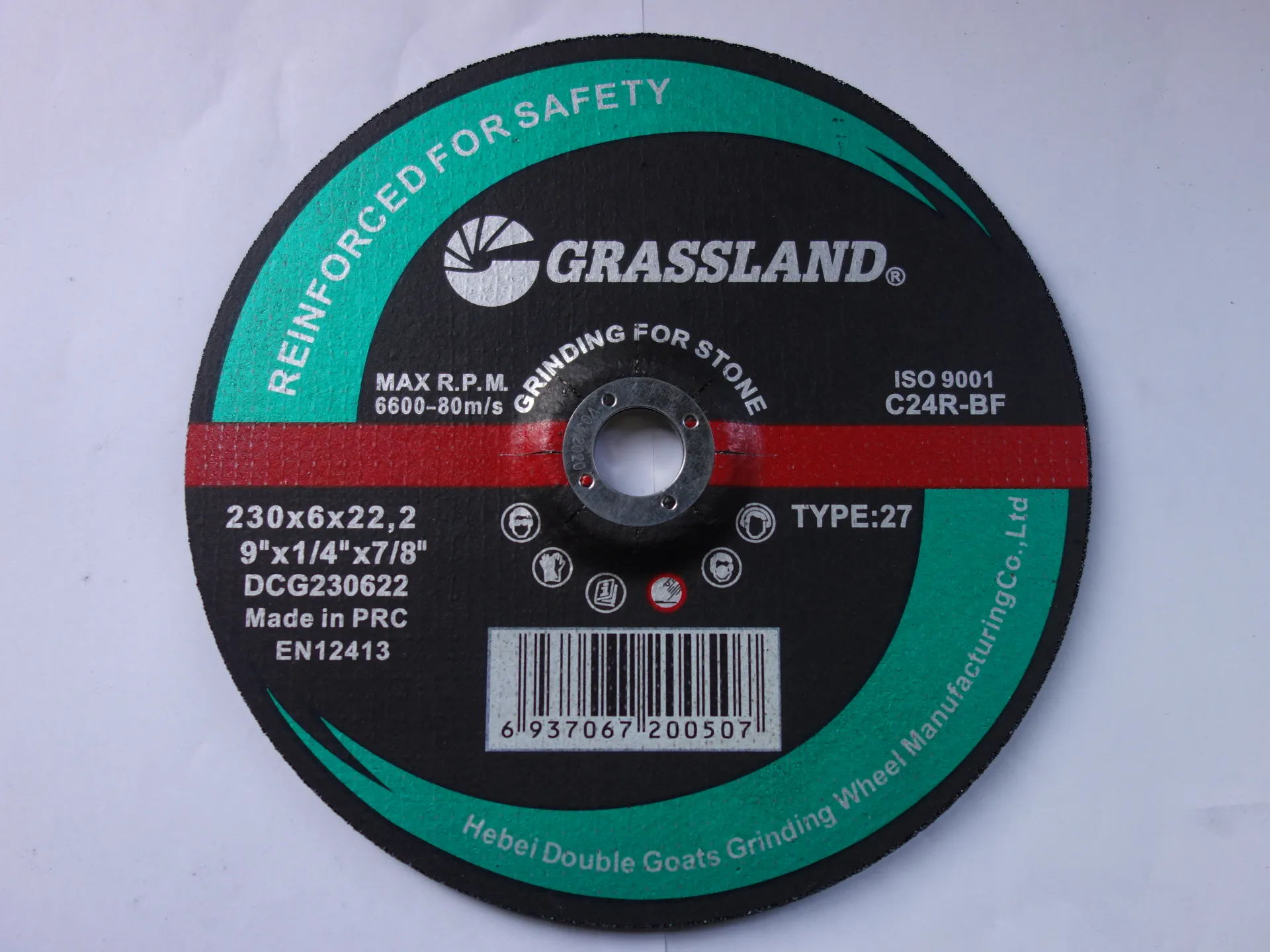

Choosing the correct grinder masonry disc is the foundation of achieving clean cuts. These discs are designed specifically for handling tough materials like concrete, bricks, and stone. The right disc not only ensures precision but also prolongs the lifespan of your equipment.

For dense materials like concrete blocks, a high-strength disc with reinforced edges is essential. On the other hand, for lighter materials, such as tiles, thinner discs offer better precision. Understanding the compatibility between your disc and the material you’re working on is key to minimizing chipping and cracking. Using a grinder stone cutting disc ensures that cuts are smooth and consistent, providing professional-grade results.

Using a Masonry Cut Off Wheel for Angle Grinder

The masonry cut off wheel for angle grinder is a versatile tool for cutting through various masonry materials. Its sharp edges and durable construction make it ideal for heavy-duty applications. However, to maximize its potential, proper handling and maintenance are crucial.

Before starting, inspect the wheel for wear or damage to avoid uneven cuts. Ensure that the wheel is securely attached to the grinder to prevent wobbling, which can lead to inaccuracies. When cutting, maintain a steady motion and let the wheel do the work—applying excessive pressure can damage both the tool and the material.

Using a cut off wheel for stone is particularly effective for hard materials, as its design minimizes dust and debris while ensuring a clean finish. To further enhance precision, mark your cutting lines clearly and follow them carefully with the masonry cut off wheel for angle grinder.

Techniques for Working with a Grinder Stone Cutting Disc

When using a grinder stone cutting disc, precision comes down to technique as much as tool selection. Start by securing your material on a stable surface. Loose or unstable materials can result in jagged edges or misaligned cuts.

Adjust your grinder to an appropriate speed for the material being cut. High speeds are more effective for dense materials, while lower speeds work well for more delicate ones. Always hold the grinder at a consistent angle—ideally 90 degrees—for straight, even cuts.

One of the most common challenges with a grinder stone cutting disc is overheating, which can cause the disc to warp. To prevent this, take breaks during prolonged cutting sessions and allow the disc to cool naturally. Additionally, always check the disc’s sharpness; a dull disc not only reduces efficiency but also compromises the quality of your cuts.

Achieving Precision with a Cutting Disc for Marble

Marble is a delicate material that requires special care and precision when cutting. A cutting disc for marble is specifically designed to handle the smooth yet brittle nature of this material. To achieve a flawless finish, use a disc with a fine grit that minimizes chipping and cracking.

Before beginning, ensure the marble is securely clamped to prevent movement. Using water as a coolant can significantly reduce heat buildup, which is a common issue when working with marble. Apply steady pressure and follow the cutting line carefully to avoid unnecessary waste.

Using the right cutting disc for marble, combined with patience and attention to detail, results in clean, polished edges that enhance the overall aesthetic of your project.

Enhancing Results with a Cut Off Wheel for Stone

For projects involving dense or irregular materials, a cut off wheel for stone is indispensable. These wheels are designed to deliver fast, precise cuts with minimal effort. Whether you’re shaping stones for a garden pathway or creating detailed architectural pieces, the versatility of this tool ensures exceptional results.

To make the most of your cut off wheel for stone, ensure it is compatible with your grinder’s specifications. Regularly check for signs of wear, such as uneven edges or a decrease in cutting efficiency. Maintaining the wheel in good condition not only improves performance but also reduces the risk of accidents.

Additionally, practice consistent cutting techniques. Avoid jerky motions or sudden changes in pressure, as these can compromise the quality of your cuts. With a steady hand and a sharp cut off wheel for stone, you can achieve precise, professional-grade results in any masonry project.

By selecting the right disc, applying proper techniques, and maintaining your equipment, you can ensure professional-grade results every time. Clean cuts not only enhance the aesthetic appeal of your work but also contribute to the durability and functionality of your projects. With the tips outlined in this guide, you’ll be well-equipped to tackle any masonry cutting task with confidence.

Post time:Dec - 26 - 2024