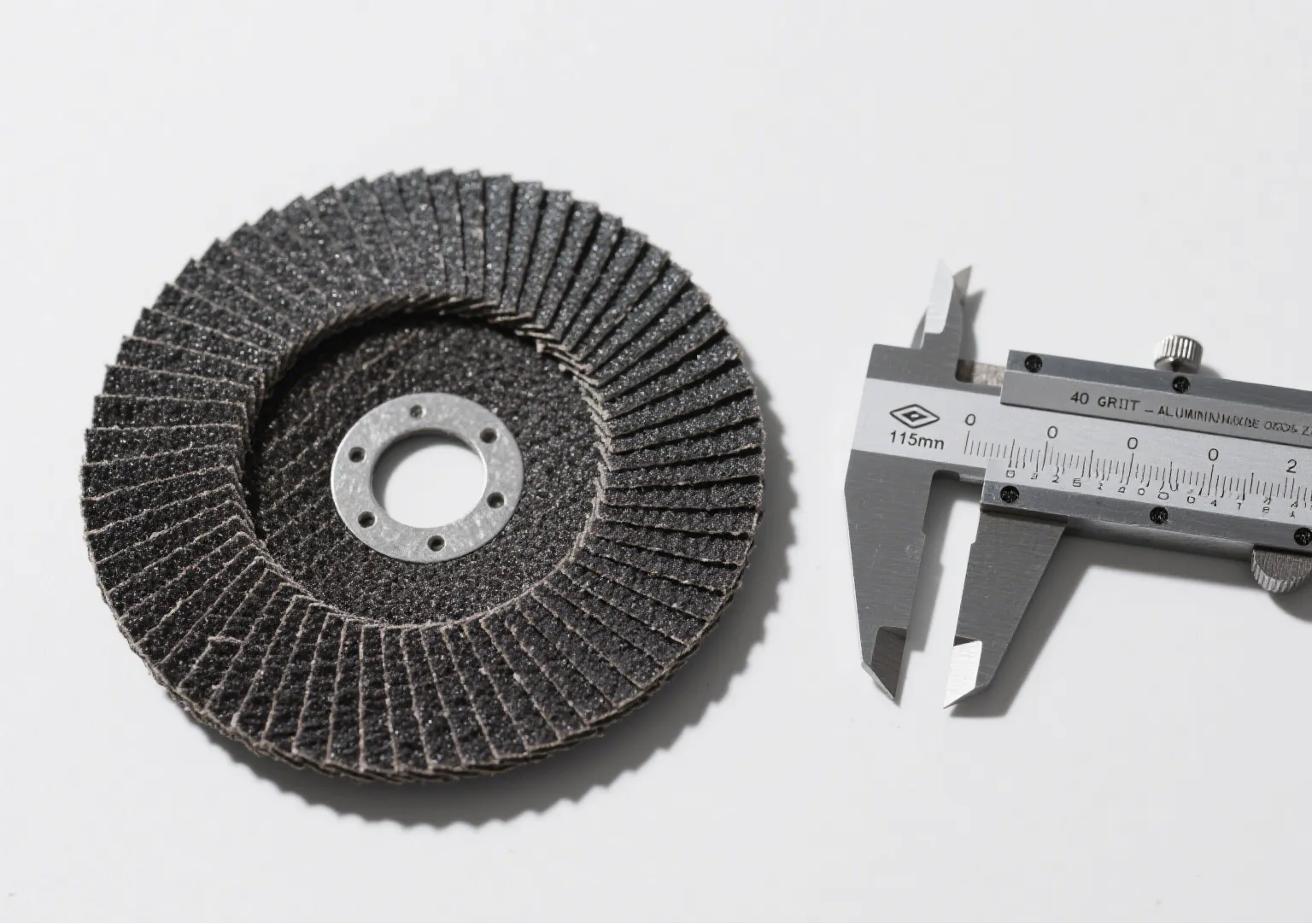

In metalworking, efficiency and precision are paramount—and professionals know that the right abrasive makes all the difference. The 40 grit flap disc has become an industry staple for heavy material removal, weld preparation, and surface blending. Also referred to as a 40 grit flap wheel or 4.5 flap disc 40 grit, this tool delivers aggressive cutting power while maintaining control.

The Unmatched Versatility of 40 Grit Flap Disc

A 40 grit flap disc for metal bridges the gap between coarse grinding and fine finishing. Its unique design combines:

Aggressive Stock Removal – Quickly strips welds, rust, and coatings.

Controlled Material Takeoff – Prevents gouging common with grinding wheels.

Smoother Finish – Reduces the need for secondary sanding.

Longer Lifespan – Durable aluminum oxide abrasives outlast standard discs.

Our flap wheel 40 grit products are EN 13743 certified, ensuring consistent performance on steel, stainless steel, and other ferrous metals.The versatility of the 40 grit flap disc makes it an ideal choice for a range of metalworking applications. Its ability to bridge the gap between coarse grinding and fine finishing allows for a more streamlined process, reducing the need for multiple tools and steps. The aggressive stock removal feature is particularly useful for tackling stubborn welds, rust, and coatings, saving time and effort. The controlled material takeoff ensures precision and prevents damage to the workpiece, which is crucial in delicate metalworking tasks. The smoother finish provided by the flap disc reduces the need for secondary sanding, further enhancing efficiency and quality. Additionally, the longer lifespan of the durable aluminum oxide abrasives means fewer replacements are needed, lowering operational costs. With its EN 13743 certification, our flap wheel 40 grit products guarantee reliable performance across various metal types, making them a trusted solution in the metalworking industry.Moreover, the 40 grit flap disc offers enhanced operator safety compared to traditional grinding wheels. The flexible flap design conforms to the contour of the workpiece, reducing the risk of accidental slips and injuries. This makes it an excellent choice for applications where safety is a top priority.In terms of environmental impact, the use of 40 grit flap discs promotes sustainability. Their long lifespan and efficient material removal reduce waste and the need for frequent disc replacements. This contributes to a more eco-friendly metalworking process, aligning with the growing trend towards green manufacturing practices.Overall, the 40 grit flap disc is a versatile, efficient, and safe tool for metalworking applications. Its unique design and certified performance make it a valuable addition to any metalworker's toolkit, enabling higher quality finishes and greater productivity.

40 Grit Flap Disc Key Applications in Professional Metalworking

The 4.5 flap disc 40 grit excels in:

Weld Preparation – Levels beads and removes spatter faster than 60+ grit discs.

Rust & Paint Stripping – Ideal for restoration projects and surface prep.

Heavy Deburring – Quickly cleans plasma-cut edges and machined parts.

Contour Grinding – Flexible flaps conform to curved surfaces.

Below compares grit performance for common tasks:

|

Task |

Ideal Grit Range |

40 Grit Advantage |

|

Weld grinding |

24#-60# |

Faster than 60# |

|

Paint removal |

36#-80# |

Less clogging than 24# |

|

Edge blending |

40#-120# |

Balanced aggression |

40 Grit Flap Disc Technical Superiority Over Alternatives

Unlike grinding wheels or lower-grit flap discs, our 40 grit flap wheel offers:

Fiberglass Backing Plate – Withstands 80 m/s (13,300 RPM) speeds.

Resin Bonded Construction – Minimizes vibration for operator comfort.

Calcium Stearate Coating – Reduces heat buildup on stainless steel.

Multi-Layer Flap Design – Self-sharpening for consistent performance.

For fabricators, this translates to:

30% faster weld cleanup vs. 60-grit discs

50% longer lifespan vs. fiber discs

Smoker transitions between ground/finished areas

40 Grit Flap Disc Maximizing Performance & Safety

To optimize your 40 grit flap disc for metal:

Use 12,000-13,300 RPM (for 115mm discs) – Check manufacturer ratings.

Employ 15-25° Angle – Maximizes contact area for efficient cutting.

Apply Moderate Pressure – Let the abrasive do the work to prevent overheating.

Rotate Workpiece Regularly – Ensures even wear across all flaps.

Our flap wheel 40 grit range includes T29 conical shapes for angled grinding and T27 flat profiles for surface work—all compliant with MPA and ISO9001 standards.

40 Grit Flap Disc FAQs

Why choose 40 Grit Flap Disc over 60 grit for metalwork?

The 40 grit flap disc removes material 25-40% faster while still providing a workable finish—ideal when prepping for paint or further refinement with finer grits.

Can 4.5 flap disc 40 Grit Flap Disc handle stainless steel?

Yes, our aluminum oxide discs include anti-loading coatings specifically for stainless. Always use dedicated discs to prevent carbon steel contamination.

How many square inches can one 40 Grit Flap Disc grind?

A quality 40 grit flap wheel typically processes 150-200 sq. in. of weld seams or 80-100 sq. ft. of rusted surface before requiring replacement.

What’s the difference between T29 and T27 40 Grit Flap Disc?

T29 (conical) suits angled grinding (15-25°), while T27 (flat) excels at surface work. Our catalog includes both for complete metalworking solutions.

Do you offer bulk pricing for fabrication shops on 40 Grit Flap Disc?

Absolutely! We provide wholesale packages with volume discounts—contact us for customized 40 grit flap disc bundles tailored to your production needs.

Post time:Sep - 01 - 2025