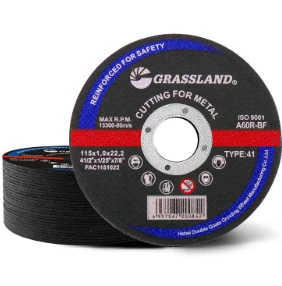

Safety is paramount in metal cutting operations. Always opt for discs manufactured by reputable brands as they are subject to rigorous quality control and safety testing, ensuring reliability and user security. The RPM (revolutions per minute) rating indicated on the disc is another critical specification. Ensure your cordless drill's RPM does not exceed the disc's limit to prevent the risk of disc shattering during operation, which can lead to injury. A well-maintained cordless drill is integral to optimizing the performance of any cutting disc. Regularly check the drill for any signs of wear and tear, and ensure the battery is reliably charged to prevent interruptions. The key advantage of a cordless drill in metal cutting is its portability; however, this is only beneficial if the tool operates at its peak efficiency. Proper maintenance ensures it remains an asset rather than a liability. In conclusion, the judicious selection of a metal cutting disc for a cordless drill transcends mere purchase. It encompasses an understanding of material compatibility—factoring in size, abrasive type, and thickness—as well as a commitment to safety and tool maintenance. This expertise ultimately contributes to achieving precise, efficient, and safe metal cutting outcomes. Opt for quality, informed choices, and diligent care, and your rewards will be manifest in both the longevity of your equipment and the excellence of your craftsmanship.

Post time:Feb - 04 - 2025