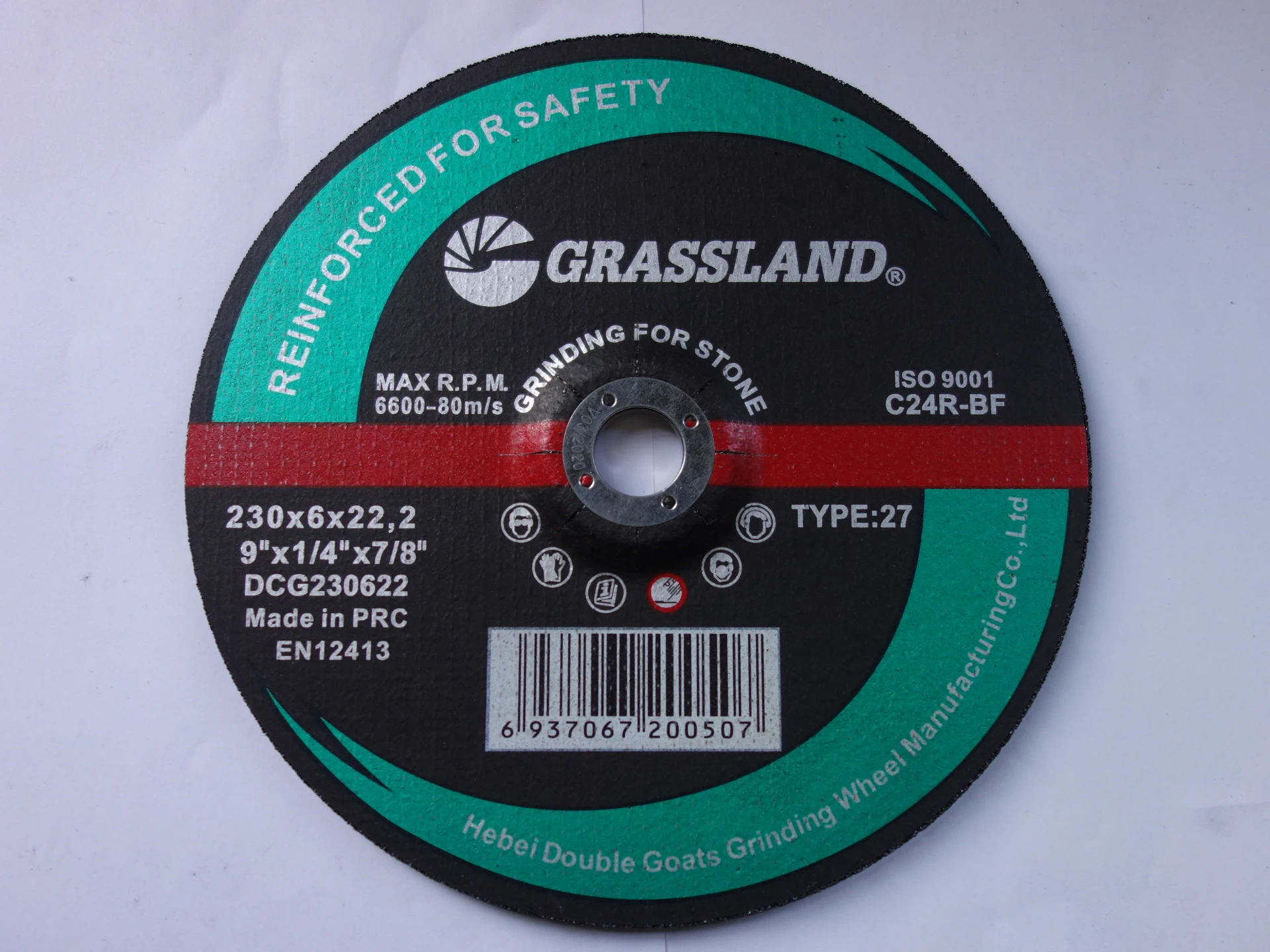

When selecting metal cutting discs, one must also consider the cutting speed. Discs are rated with a maximum number of revolutions per minute (RPM). Using a disc beyond its rated speed can result in catastrophic failure. Therefore, always verify that your angle grinder's RPM does not exceed the disc's maximum. A professional's insight often highlights maintaining consistent pressure while cutting. Too much pressure can overheat the disc, leading to warping or uneven cuts, while too little pressure might cause the disc to slowly dig into the material, reducing efficiency. Let the disc do the work, guiding it smoothly through the metal. Manufacturers often offer additional features like reinforced discs with fiberglass backing, enhancing safety and extending lifespan. Checking for these options can be beneficial for intensive cutting tasks. Furthermore, for specialized tasks such as cutting stainless steel or using a grinder with variable speed, choosing discs designed specifically for these purposes can improve results dramatically. Ensuring trustworthiness in your tools begins with purchasing from reputable brands or sellers. Well-known manufacturers invest significantly in testing and quality assurance, ensuring you receive a product that meets both safety standards and performance expectations. Certificates of compliance with ISO or EN safety standards are good indicators of reliable discs. Ultimately, mastering the use of metal cutting discs for an angle grinder is a blend of selecting the right product and applying accurate techniques. With experience, you’ll discern the subtle differences in disc performance and application, allowing for smoother, more precise cuts. Whether tackling a complex metalworking project or making simple straight cuts, using the right disc is pivotal in achieving professional results efficiently and safely.

Post time:Feb - 03 - 2025