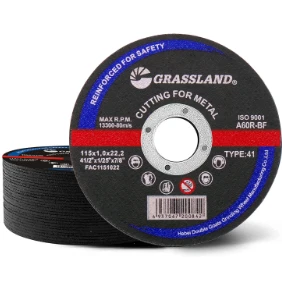

Bonding Basics The bonding agent holds the abrasive grains together and influences the wheel's cutting behaviour. Resin-bonded wheels are most common, as they provide a balance between cutting performance and wear resistance. For frequent, heavy-duty cutting, consider wheels with reinforced fiberglass, which offer additional strength and safety. Safety First Using the wrong cutting wheel can result in wheel breakage, which poses serious injury risks. Always follow manufacturer guidelines and regulations, such as wearing appropriate personal protective equipment (PPE), ensuring guards are in place, and maintaining your saw regularly. Expert Tips for Optimal Performance 1. Test Before Use Before cutting, let the wheel run for a full minute to check for defects or imbalance. 2. Correct Speed Verify the maximum RPM rating of the wheel and ensure your chop saw doesn’t exceed it. This prevents overheating and potential failure. 3. Secure the Material A stable workpiece and using clamps can prevent slippage during cutting, leading to cleaner results and increased safety. 4. Proper Storage Keep your wheels dry and protected to avoid moisture damage, which can compromise integrity. 5. Regular Inspections Assess wheels for wear or damage, especially if you notice decreased cutting efficiency or unusual vibrations. The Significance of Trustworthiness Relying on reputable brands when selecting your metal cutting wheel is crucial. Trusted manufacturers invest in research and development, ensuring their products meet industry standards and safety regulations. Moreover, these brands often provide accurate specifications and user guides to assist in making informed decisions. Final Thoughts Choosing the right metal cutting wheel for your chop saw is a decision that balances material characteristics, wheel dimensions, and safety protocols. By understanding the nuances of these components, you not only enhance your metalworking capabilities but also ensure a safer and more efficient workspace. Rely on quality and expertise, and you’ll find that the perfect wheel transforms your metal cutting projects into precise, seamless endeavors.

Post time:Feb - 11 - 2025