Understanding Metal Discs for Grinders An Essential Component for Efficient Grinding

Metal discs, often referred to as grinding discs or wheels, are critical components in the functionality of various grinders, including angle grinders and bench grinders. These discs are essential for both professional and DIY projects, allowing users to smooth, shape, or polish metal surfaces. Understanding the different types of metal discs available and their respective applications can greatly enhance the effectiveness and safety of your grinding tasks.

Types of Metal Discs

There are several types of metal discs available, each designed for specific applications. Here are some of the most common varieties

1. Grinding Discs These are typically used for heavy material removal. Grinding discs are made from various materials, including aluminum oxide and zirconia, which provide durability and efficiency when tackling tough metal surfaces.

2. Cutting Discs Cutting discs are thinner and are specifically designed for slicing through metal materials. These discs can be used for cutting rebar, pipes, and various sheets of metal without excessive heat generation, thus preserving the integrity of the metal.

3. Flap Discs Flap discs combine the functions of both grinding and finishing, making them versatile tools for metal processing. They consist of multiple overlapping pieces of sandpaper attached to a backing plate. Flap discs are excellent for blending and finishing surfaces while providing effective material removal.

4. Polishing Discs These are used for enhancing the surface finish of metal. Polishing discs are typically softer and help achieve a mirror-like finish. They are often used in conjunction with polishing compounds to maximize the final appearance of the metal.

Factors to Consider When Choosing Metal Discs

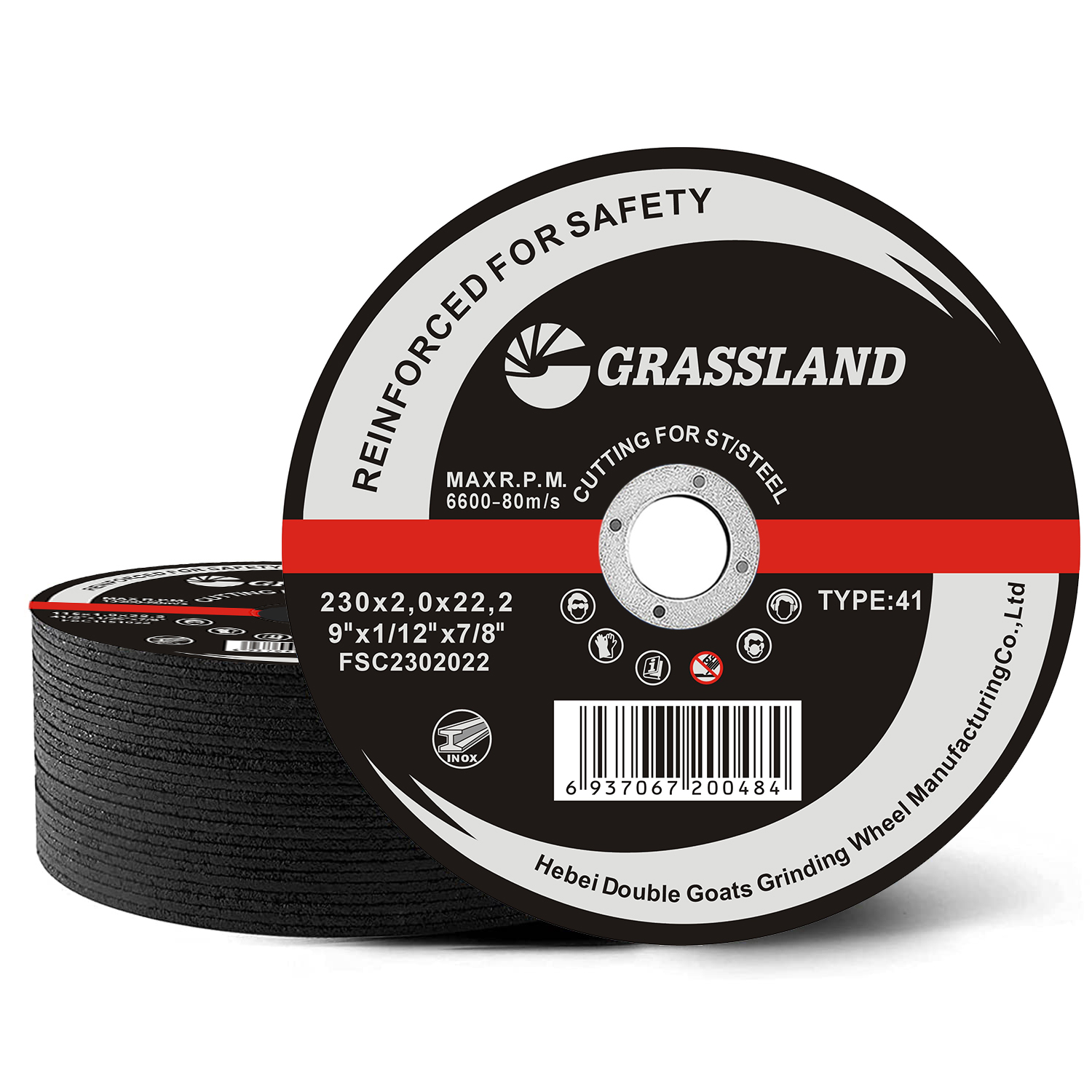

metal disc for grinder

When selecting the right grinding or cutting disc for your project, there are several factors to consider

1. Material Compatibility Ensure that the disc you choose is compatible with the type of metal you’ll be working with. Some discs are specifically formulated for ferrous metals like steel, while others excel in non-ferrous materials like aluminum.

2. Grip and Safety Pay attention to the disc's design. Look for discs with a reinforced backing that can withstand high speeds, especially when using an angle grinder. Always prioritize safety by wearing appropriate protective gear, including goggles and gloves, while working.

3. Disc Thickness The thickness of the disc will also influence its performance. Thicker discs are suited for heavy grinding tasks, whereas thinner discs are better for precise cutting and less material removal.

4. Grain Structure The grain structure of the disc determines its aggressiveness. Coarser grains facilitate faster material removal, while finer grains are ideal for finishing and polishing work.

Safety Precautions

Using metal discs for grinding requires adherence to safety guidelines to prevent accidents. Here are some essential safety tips

- Always inspect discs before use for any signs of wear or damage. - Ensure that the grinder is turned off and unplugged when changing discs. - Use the appropriate disc for your specific grinder to avoid accidents caused by mismatched equipment. - Maintain a firm grip on the tool and use both hands whenever possible for better control. Conclusion

In summary, metal discs are indispensable tools in metalworking. Whether used for grinding, cutting, or polishing, selecting the appropriate type of disc is vital for achieving quality results and ensuring safety during operation. By understanding the different types of metal discs available and adhering to safety practices, you can enhance your efficiency and effectiveness in any metalworking project. Investing in high-quality discs may seem like a small detail, but it can significantly impact the quality and smoothness of your finished work.

Post time:Nov - 14 - 2024