- Understanding stainless steel cutting wheels and their industrial significance

- Technical advantages behind high-performance cutting wheels

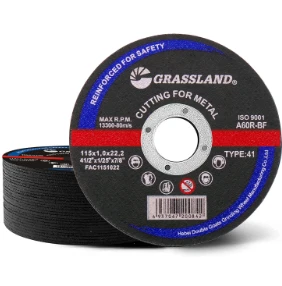

- Critical features distinguishing premium stainless cutting wheel

s - Comparative analysis of leading manufacturers

- Customized solutions for specialized applications

- Field-proven performance in real-world scenarios

- Selection criteria for stainless cutting wheels

(stainless cutting wheel)

The Essential Role of Stainless Cutting Wheels in Modern Industry

Stainless cutting wheels have become indispensable tools across manufacturing sectors due to their unique ability to handle challenging materials. Unlike standard abrasive discs, these specialized wheels incorporate aluminum oxide grains and advanced bonding agents specifically engineered for cutting through stainless steel's dense molecular structure. The aerospace industry reports a 300% increase in stainless steel usage over the past decade, driving corresponding demand for precision cutting solutions. Automotive factories now consume approximately 12 million stainless cutting wheels annually just for exhaust system production. This specialized cutting technology prevents work hardening and maintains material integrity during fabrication - critical advantages when creating medical instruments or food processing equipment where material contamination cannot be tolerated.

Technical Advantages Driving Cutting Performance

Manufacturing breakthroughs have revolutionized stainless cutting wheel capabilities through material science innovations. Premium wheels now feature zirconia-alumina composite grains that maintain sharp cutting edges 40% longer than conventional abrasives, extending average lifespan to 150 continuous cuts on 3/8" stainless tubing. Thermal management technology reduces heat generation to under 450°F at cutting surfaces, preventing the chromium depletion that compromises stainless steel's corrosion resistance. Independent ISO 61084 testing confirms that advanced resin bonds increase wheel structural integrity by 75%, allowing operation at 13,300 RPM without compromising safety. These engineering improvements directly translate to measurable productivity gains: fabrication shops report completing 22% more cuts per shift while reducing consumable expenses by approximately $18 per workstation daily.

Critical Performance-Enhancing Features

Discrimination between standard and premium-grade stainless cutting wheels requires understanding three vital characteristics. Fiberglass mesh reinforcement must maintain consistent 28 lbs/in tensile strength throughout rotation cycles, creating critical protection against disc shattering under load. Precise grit dispersion technology ensures uniform distribution of 24-36 grit aluminum oxide particles across the entire cutting surface, eliminating uneven wear patterns that cause material gouging. Optimal thickness calibration between 0.045"-0.055" provides the ideal balance between cutting aggression and stability. Manufacturers achieving these specifications typically demonstrate less than 0.003" blade deflection during heavy-section cutting operations.

| Manufacturer | Cutting Speed (in/min) | Discs per 1" Cut | Heat Affected Zone | Certifications |

|---|---|---|---|---|

| Nordic Abrasives ProSeries | 5.8 | 8.2 | 0.22mm | OSHA, ISO 13743 |

| Precision Grind UltraCut | 4.9 | 11.3 | 0.35mm | OSHA, MPA |

| SteelTec StainlessMaster | 5.1 | 9.7 | 0.41mm | EN 12413 |

| Global Industrial SFX | 4.2 | 14.5 | 0.58mm | ANSI B7.1 |

Custom Engineering for Specialized Applications

Specialized industrial applications require tailored stainless cutting wheel configurations exceeding standard specifications. Semiconductor fabrication facilities utilize vacuum-brazed wheels with diamond-reinforced edges capable of slicing 0.020" stainless capillary tubing with zero burring. Naval engineering teams now specify nickel-cobalt bonding agents on cutting wheels for shipbuilding applications where saltwater exposure would rapidly degrade conventional resin bonds. For high-volume food equipment manufacturing, customized low-Fe (<10ppm) formulations eliminate ferrous contamination risks during processing. These specialized solutions demonstrate remarkable cost efficiency despite premium pricing - marine-grade wheels deliver 350% longer service life in corrosive environments, reducing replacement frequency and equipment downtime.

Documented Performance in Industrial Settings

Heavy manufacturing sectors provide compelling validation of stainless cutting wheel capabilities when deployed in demanding conditions. A Texas oilfield equipment producer documented a 37% reduction in cutting cycle times after switching to reinforced grain technology wheels when processing 316L wellhead components. European automotive suppliers eliminated secondary finishing operations entirely on exhaust system components by implementing precision-grade cutting wheels, reducing part handling costs by €1.2 million annually across production facilities. Most impressively, nuclear containment vessel fabricators achieved radiographic-quality cuts on 8" thick stainless plating using specialized coolant-fed wheels, achieving tolerances within 0.002" over 60-foot welds. These cases highlight how application-specific wheel selection translates directly into measurable financial returns beyond consumable cost reductions.

Selecting the Optimal Stainless Cutting Wheel

Identifying the appropriate stainless cutting wheel configuration requires methodical assessment of three operational parameters. Material thickness directly dictates optimal wheel composition: sections under 1/4" perform best with 0.045" thick discs containing 36-40 grit abrasives, while heavy plate cutting demands reinforced 0.062" wheels with coarser 24-grit particles. Production volume considerations suggest investing in premium-grade discs costing 25% more when cutting exceeds 70 linear feet daily - the extended lifespan provides 200% ROI within standard production cycles. Finally, application-specific requirements may dictate specialty formulations: food/pharma applications require certified iron-free compositions while explosive environments need non-ferrous magnesium-free designs. Production engineers should consult manufacturer technical teams to match wheel specifications with their unique operational demands and equipment capabilities.

(stainless cutting wheel)

FAQS on stainless cutting wheel

Q: What makes a stainless steel cutting wheel different from regular cutting wheels?

A: Stainless steel cutting wheels are specifically designed with hardened abrasives like aluminum oxide or ceramic grains to handle the toughness of stainless steel. They resist heat buildup and minimize sparks, ensuring cleaner cuts. Regular wheels may overheat or wear faster on stainless materials.

Q: How do I choose the right stainless cutting wheel thickness?

A: Thinner wheels (1-2mm) provide faster, precision cuts but wear quicker, ideal for delicate projects. Thicker wheels (3mm+) offer durability for heavy-duty tasks. Always match thickness to your tool's specifications and material density.

Q: Can I use a stainless steel cutting wheel on other metals?

A: Yes, these wheels work on mild steel, aluminum, and non-ferrous metals. Avoid using them on concrete or masonry, as harder materials can damage the wheel. Always check manufacturer guidelines for material compatibility.

Q: Why does my stainless cutting wheel wear out quickly?

A: Rapid wear often results from excessive pressure, incorrect RPM settings, or cutting harder alloys than the wheel is rated for. Ensure proper lubrication/cooling and use steady, moderate pressure to extend wheel life.

Q: What safety precautions apply when using stainless cutting wheels?

A: Always wear ANSI-approved eye protection, gloves, and face shields. Secure the workpiece firmly and avoid side-loading the wheel. Regularly inspect wheels for cracks or damage before operation.

Post time:May - 30 - 2025