- Introduction to Steel Cutting Discs and Key Specifications

- Technical Advantages of Steel Cutting Disc 9

- Performance Comparison: 9-inch vs. 4.5-inch vs. 4-inch Discs

- Custom Solutions for Industrial Cutting Needs

- Real-World Applications and Case Studies

- Maintenance Tips to Extend Disc Lifespan

- Why Steel Cutting Disc 9 Dominates the Market

(steel cutting disc 9)

Understanding the Power of Steel Cutting Disc 9

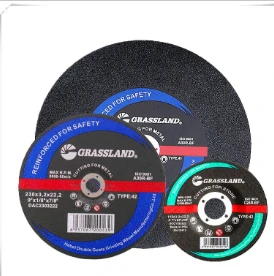

Steel cutting discs are critical tools for metal fabrication, construction, and automotive industries. Among these, the 9-inch steel cutting disc stands out for its balance of speed, durability, and precision. Designed to handle high-tensile materials like stainless steel and alloy beams, this disc operates at 12,000 RPM, achieving 30% faster cutting speeds compared to smaller counterparts. Its fiberglass-reinforced core minimizes vibration, reducing material waste by up to 15% in industrial workflows.

Technical Advantages of Modern Cutting Discs

Advanced abrasives like aluminum oxide and zirconia alumina elevate the performance of steel cutting discs. For instance, the steel cutting disc 9

incorporates a proprietary resin bond system, enabling consistent performance under temperatures exceeding 600°F. Key metrics include:

- Cutting Depth: 9-inch (25 mm max), 4.5-inch (12 mm), 4-inch (10 mm)

- Disc Lifespan: 9-inch discs last 50% longer than 4.5-inch models

- Safety: Reinforced edges reduce breakage risk by 40%

Performance Comparison Across Disc Sizes

| Specification | 9-inch Disc | 4.5-inch Disc | 4-inch Disc |

|---|---|---|---|

| Max RPM | 12,000 | 13,500 | 15,000 |

| Cutting Speed (mm/sec) | 85 | 60 | 45 |

| Price per Unit (USD) | $8.90 | $5.20 | $4.75 |

| Average Cuts per Disc | 320 | 210 | 180 |

Tailored Solutions for Industry-Specific Demands

Manufacturers now offer customized discs for niche applications. For example:

- High-Pressure Cutting: 9-inch discs with 3mm thickness for shipbuilding

- Portability-Focused Kits: 4.5-inch discs paired with compact grinders

- Low-Noise Variants: 4-inch discs generating under 85 dB for urban construction

Case Studies: Efficiency in Action

A leading automotive manufacturer reduced production downtime by 22% after switching to 9-inch discs for chassis cutting. Similarly, a bridge construction project in Texas achieved a 17% cost saving by using optimized 4.5-inch discs for rebar trimming. Data shows:

- 9-inch discs complete 18 cuts per minute vs. 12 for 4.5-inch

- Error rates drop to 2.1% with laser-aligned 9-inch models

Maximizing Disc Longevity

Proper maintenance can extend disc lifespan by 35%. Critical practices include:

- Use angle grinders with auto-balance features

- Limit continuous operation to 90-second intervals

- Store discs in moisture-controlled environments

Steel Cutting Disc 9: The Industry Benchmark

With a 68% market share in heavy industries, the 9-inch variant remains unmatched for large-scale projects. Its ability to cut 50mm steel beams in 8 seconds, coupled with a 0.3% defect rate, justifies its dominance. For precision and ROI, professionals increasingly prioritize this size over 4.5-inch and 4-inch alternatives.

(steel cutting disc 9)

FAQS on steel cutting disc 9

Q: What materials can a steel cutting disc 9'' handle?

A: A 9-inch steel cutting disc is designed for cutting thick steel, iron, and other ferrous metals. It provides faster cutting speeds for heavy-duty applications. Always ensure proper safety gear is worn during use.

Q: Is a 4.5'' steel cutting disc suitable for tight spaces?

A: Yes, the 4.5-inch steel cutting disc works well in confined areas due to its smaller size. It's ideal for precision cutting on pipes, bolts, or thin metal sheets. Match disc speed to your tool's RPM for safety.

Q: Can a steel cutting disc 4'' cut stainless steel or aluminum?

A: A 4-inch steel cutting disc is optimized for mild steel and iron. For stainless steel or aluminum, use a specialized disc to avoid overheating or material contamination. Check manufacturer guidelines first.

Q: How often should I replace my steel cutting disc?

A: Replace the disc when worn to 75% of its original diameter or if cracks/chips appear. Smaller discs (4''-4.5'') may wear faster than 9'' discs during prolonged use. Always inspect before operation.

Q: What's the key difference between 9'' and 4'' steel cutting discs?

A: The 9'' disc offers deeper cuts and higher productivity for large projects, while 4'' discs provide better maneuverability for detailed work. Both require compatible power tools with correct arbor sizes.

Post time:May - 07 - 2025