Understanding the Type 27A Cutting Wheel Features, Applications, and Best Practices

The Type 27A cutting wheel is a specialized tool widely used in metalworking, construction, and engineering applications. Recognized for its versatility and efficiency, the Type 27A is a flat wheel designed for cutting metal, making it an essential component in various industries. This article delves into the features, applications, and best practices for using the Type 27A cutting wheel.

Features of the Type 27A Cutting Wheel

1. Design and Structure The Type 27A cutting wheel typically features a flat design, which allows for efficient cutting along the surface of the material. Its structure usually incorporates a reinforced mesh that enhances durability and reduces the risk of breakage during heavy-duty applications.

2. Material Composition These cutting wheels are often made from high-quality aluminum oxide or zirconia, which are known for their hardness and longevity. This material selection ensures that the wheels can withstand high temperatures and resist wear, providing a longer service life and consistent cutting performance.

3. Size and Thickness Type 27A cutting wheels come in various sizes and thicknesses, typically ranging from 4 to 9 inches in diameter and varying thickness to meet different cutting requirements. Thinner wheels are ideal for precise cuts, while thicker wheels provide more stability for tougher materials.

4. Versatility One of the standout features of the Type 27A cutting wheel is its versatility. It can be used on a variety of metals including stainless steel, aluminum, and mild steel. This adaptability makes it a favorite among professionals in diverse fields from plumbing to automotive repair.

Applications of the Type 27A Cutting Wheel

The Type 27A cutting wheel finds applications in numerous industries due to its efficacy and reliability

2. Construction In the construction industry, contractors use Type 27A wheels to cut through rebar, metal studs, and other structural materials. This capability is critical for ensuring the precise execution of construction projects.

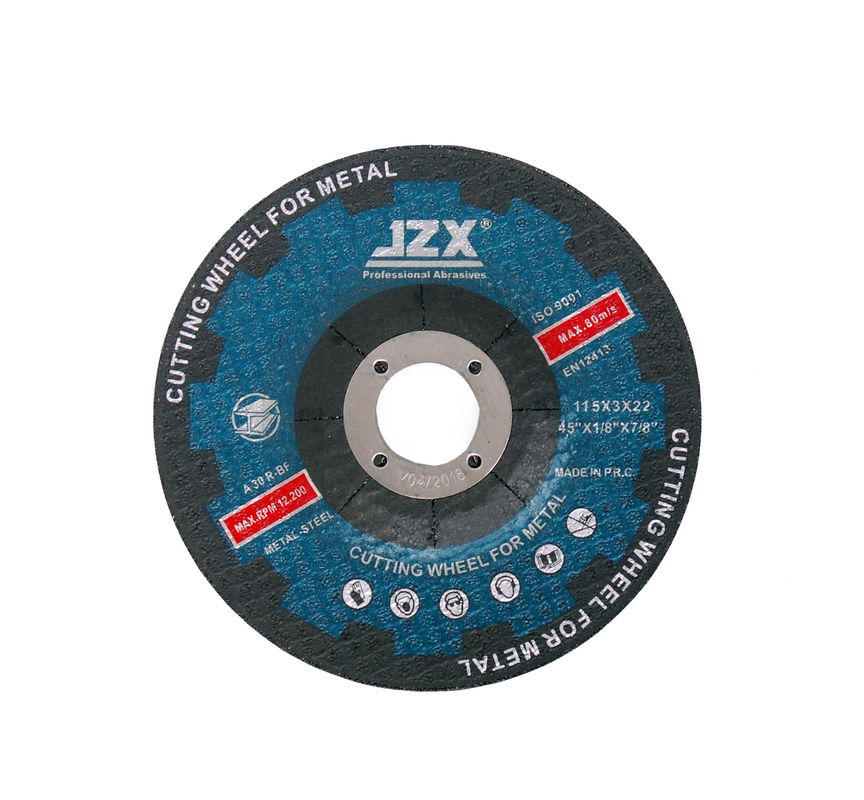

type 27a cutting wheel

3. Automotive Industry Automobile repair shops utilize cutting wheels to remove rusted parts, cut exhaust pipes, and perform general maintenance tasks, where quick and efficient metal cutting is required.

4. Maintenance and Repair DIY enthusiasts and maintenance professionals often rely on Type 27A cutting wheels for tasks that involve cutting metal in various appliances and machinery.

Best Practices for Using Type 27A Cutting Wheels

To maximize the effectiveness and safety of Type 27A cutting wheels, users should follow these best practices

1. Safety Gear Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and a face shield to protect against sparks and metal shards during cutting.

2. Proper Equipment Use the right type of grinder or cutoff tool that matches the specifications of the Type 27A wheel. An underpowered tool may overheat the wheel, while using an unsuitable tool can lead to accidents.

3. Correct Technique Ensure that the cutting wheel is being used at the correct angle; typically, an angle of 90 degrees to the workpiece provides the best results. Also, apply moderate pressure and allow the tool to do the work instead of forcing it, which can enhance performance and prolong wheel life.

4. Storage and Handling Store cutting wheels in a dry place away from direct sunlight and extreme temperatures. Handling them with care is essential to prevent damage or cracks that can lead to failure during use.

Conclusion

The Type 27A cutting wheel is a vital tool that offers efficiency and reliability in various cutting applications. Its versatile design, durability, and adaptability make it an indispensable component in numerous industries. By following best practices and understanding its features and applications, users can ensure optimal performance and safety when working with this essential tool. Whether in professional settings or DIY projects, the Type 27A cutting wheel continues to be a trusted choice for metal cutting tasks.

Post time:Dec - 25 - 2024