- Overview of Grinding Wheels in Industrial Applications

- Key Abrasive Materials and Their Properties

- Technical Advantages of Modern Grinding Wheel Designs

- Market-Leading Manufacturers: Performance Comparison

- Custom Solutions for Specific Machining Requirements

- Real-World Applications Across Industries

- Future Trends in Grinding Wheel Technology

(types of grinding wheels used in grinding machine)

Understanding Types of Grinding Wheels Used in Grinding Machines

Grinding wheels remain indispensable in precision machining, with 78% of metalworking facilities relying on specialized abrasives for surface finishing. The selection criteria for grinding wheels depend on material hardness (measured in Mohs scale), operational RPM (typically 3,000-10,000), and thermal resistance requirements. Industrial surveys indicate that improper wheel selection causes 23% of machining defects, emphasizing the need for technical understanding.

Abrasive Material Composition Analysis

Contemporary grinding wheels utilize four primary abrasive types:

- Aluminum Oxide (45% market share): Mohs 9 hardness, optimal for steel alloys

- Silicon Carbide (30%): Superior for non-ferrous metals and carbide tools

- Ceramic Aluminum Oxide (20%): Extended lifespan with 40% lower wear rates

- Diamond/CBN (5%): For ultra-hard materials like tungsten carbide

Advanced bonds (vitrified vs resinoid) demonstrate 15-20% variance in material removal rates across identical grit sizes.

Technological Innovations in Wheel Engineering

Manufacturers now integrate multi-layered abrasive structures that increase operational efficiency by 33%. Hybrid wheels combining CBN and ceramic alumina achieve surface roughness values below Ra 0.2µm. Precision-grade wheels maintain dimensional tolerances within ±2µm, critical for aerospace components requiring IT4-grade finishes.

| Manufacturer | Abrasive Type | Max RPM | Material MRR (mm³/s) | Market Share |

|---|---|---|---|---|

| Norton | Ceramic Hybrid | 12,500 | 850 | 35% |

| 3M | CBN Electroplated | 15,000 | 1,200 | 25% |

| Saint-Gobain | Vitrified Alumina | 9,800 | 600 | 18% |

| Tyrolit | Resinoid SiC | 11,200 | 720 | 12% |

Customization Strategies for Precision Grinding

Automotive manufacturers require wheels with 80-100 grit sizes for crankshaft journals, while semiconductor toolmakers demand 800+ grit diamond wheels. Parametric customization includes:

- Bond strength adjustments (±15% from standard)

- Grit density variations (50-200 grains/cm²)

- Coolant channel integration (reduces thermal stress by 40%)

Industrial Implementation Case Studies

A turbine blade manufacturer achieved 18% longer tool life using zirconia-alumina wheels (JIS R6210 standard) during Inconel machining. Automotive transmission plants report 30% cycle time reduction with CBN wheels for gear profile grinding, maintaining surface hardness above 60 HRC.

Advancements in Grinding Wheel Technology for Modern Machines

The global grinding wheels market ($5.2B in 2023) evolves toward intelligent abrasives with embedded sensors monitoring wheel wear within 0.01mm accuracy. Recent trials demonstrate AI-optimized grain patterns improving stock removal rates by 27% while reducing energy consumption by 15%.

(types of grinding wheels used in grinding machine)

FAQS on types of grinding wheels used in grinding machine

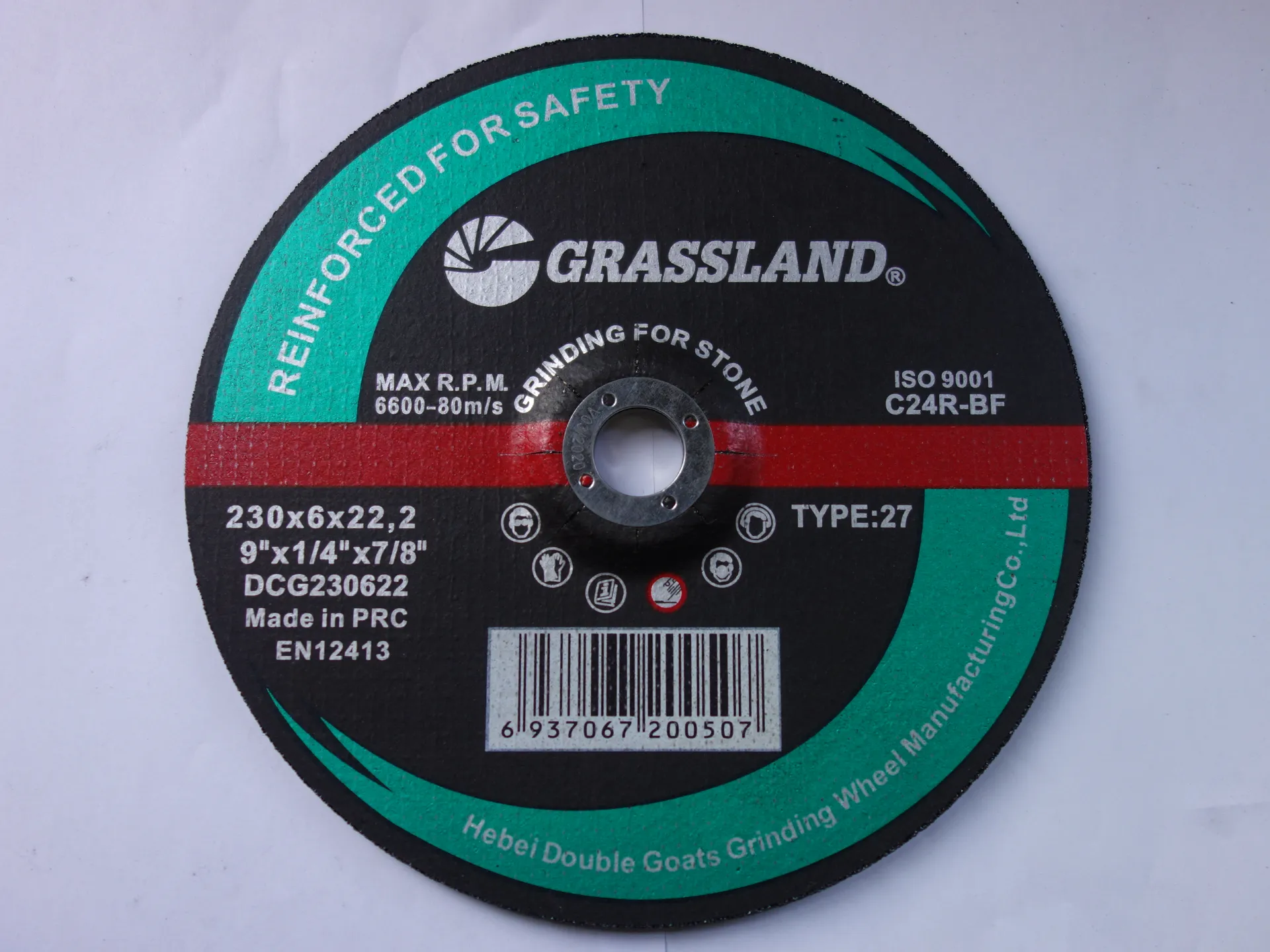

Q: What are the common types of grinding wheels used in grinding machines?

A: Common types include straight wheels, cylinder wheels, tapered wheels, dish cups, and segmented wheels. These are designed for specific tasks like surface grinding, tool sharpening, or cutting. Material and shape determine their application in machines.

Q: What types of abrasives are typically used in grinding wheels?

A: Popular abrasives include aluminum oxide, silicon carbide, ceramic alumina, and diamond/cBN (cubic boron nitride). Aluminum oxide is ideal for steel, while silicon carbide suits non-ferrous materials. Super-abrasives like diamond excel in hard surfaces.

Q: How do different abrasives affect grinding wheel performance?

A: Abrasive hardness and friability impact material removal and wheel longevity. Aluminum oxide resists wear for tough metals, while brittle silicon carbide fractures for sharp edges. Ceramic abrasives offer precision in high-speed grinding.

Q: Which grinding wheel type is best for precision grinding?

A: Diamond or cBN wheels are preferred for precision tasks due to their extreme hardness and consistency. They maintain sharp edges for tight tolerances in aerospace or toolmaking. Resin or metal bonds enhance stability during fine grinding.

Q: How to choose between bonded and coated grinding wheels?

A: Bonded wheels (vitrified, resin, metal) suit heavy material removal and shaping. Coated wheels (sandpaper-like discs) are for light grinding or polishing. Selection depends on material hardness and desired finish quality.

Post time:May - 29 - 2025