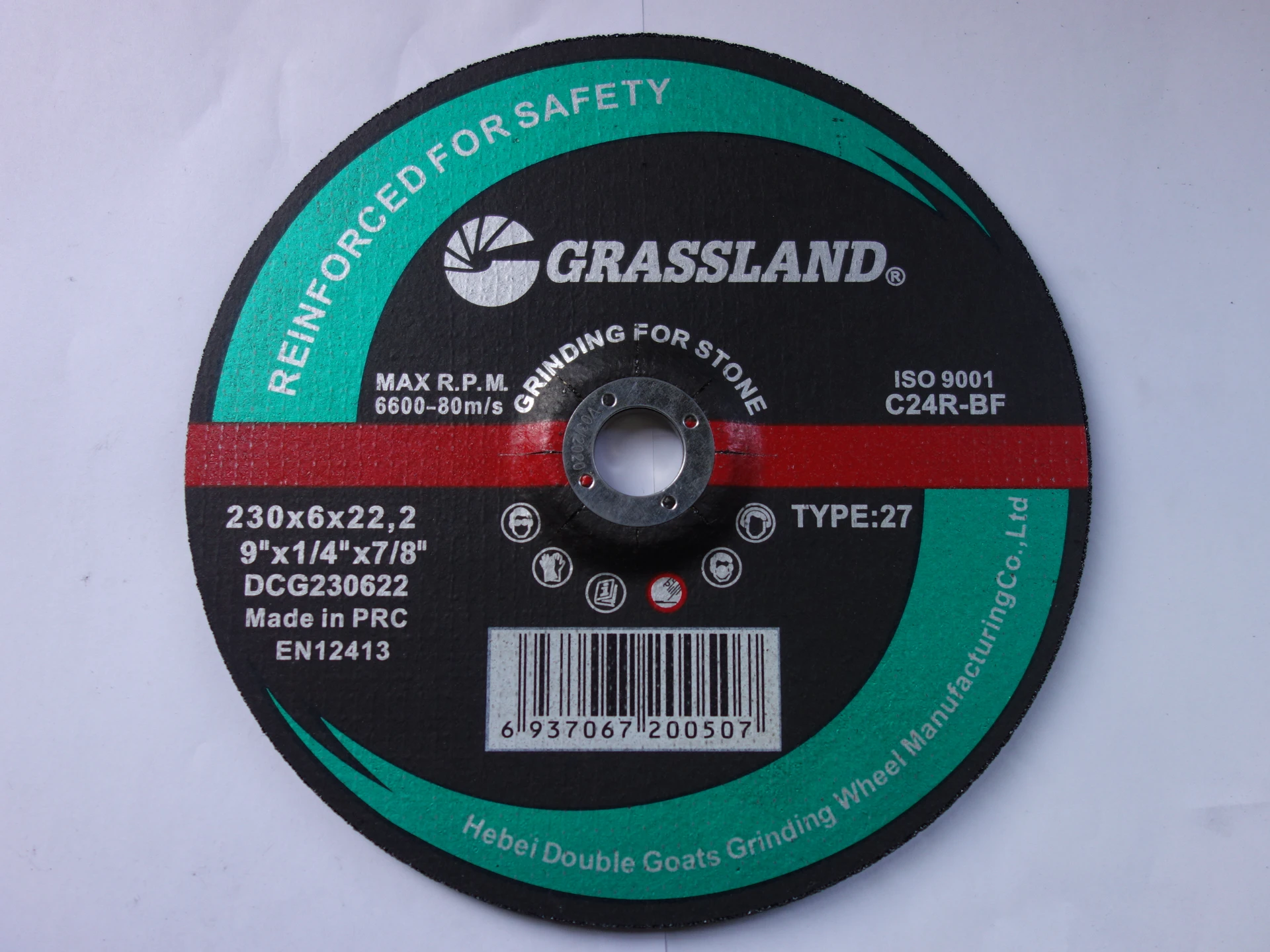

4. Thickness of the Wheel Opt for a thinner wheel to ensure a faster cut with minimal heat. While thicker wheels are robust, they might hinder cutting precision and increase thermal stress on the material. 5. Speed Rating Choose a wheel with an appropriate speed rating that matches your equipment settings. Ensuring compatibility aids in maintaining safety and effectiveness during operation, ultimately extending the life of the wheel. 6. Anti-Clog Coatings Consider wheels with specialized coatings designed to prevent clogging, known as loading. These coatings facilitate better chip clearance—crucial for achieving smooth, accurate cuts in aluminum. Expert Recommendations and Real-World Experience In the industry, professionals frequently recommend wheels like the 3M Cubitron II or those featuring zirconia alumina for their efficiency and minimized abrasive loading. Users consistently report smoother operations and superior results, emphasizing the significance of using specialized products tailored for aluminum applications. Additionally, ensuring proper safety gear, such as goggles and gloves, significantly enhances operational safety, safeguarding against debris and shards during cutting. Trust through Manufacturer Credentials Always source cut-off wheels from reputable manufacturers with proven track records in producing industrial-grade abrasives. Look for certifications that underscore their commitment to quality, safety, and innovation, ensuring reliable performance tailored to the specific demands of aluminum cutting. Harnessing industry knowledge and leveraging appropriate equipment ensures that both amateurs and seasoned professionals alike achieve exceptional outcomes. By understanding and implementing these insights, cutting aluminum becomes not only highly efficient but also a professionally gratifying experience.

Post time:Feb - 10 - 2025