In the world of metal fabrication and construction, having the right cutting tools can significantly improve productivity and precision. Among the most versatile and widely used tools are cutting discs designed for a variety of materials. The 5 in cut off wheel stands out as a popular choice due to its compact size and robust performance, enabling workers to make clean cuts with minimal effort. Whether working on carbon steel, stainless steel, or other metals, these wheels deliver reliable results for both professional and DIY projects.

Durable Performance Offered by the 5 in Cut Off Wheel in Metalworking

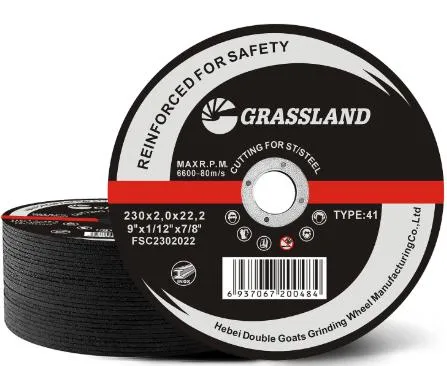

A key factor that influences buying decisions is the 5 in cut off wheel’s ability to maintain sharpness and stability during intense cutting tasks. This wheel is engineered to provide clean, accurate cuts while resisting overheating and premature wear. Thanks to advanced bonding techniques and high-quality abrasive materials, it can handle a wide range of applications, from cutting through carbon steel sheets to trimming pipes. The durability of this cutting wheel makes it a favorite among fabricators seeking consistent performance without frequent replacements.

Cutting Disc 5 Inch: Versatility for Various Industrial Uses

When discussing cutting tools, the cutting disc 5 inch is praised for its adaptability across industries. Its size strikes the perfect balance between maneuverability and cutting capacity, making it suitable for detailed tasks as well as heavy-duty work. Not only does this disc excel at slicing through metal, but it also performs well on other materials like concrete and stone, depending on the specific disc composition. The variety of options available within the 5-inch category allows users to select discs tailored to their precise needs.

Understanding the 5 Inch Cutting Wheel Price in Relation to Quality and Application

Investing in cutting tools often comes down to balancing cost with long-term value. The 5 inch cutting wheel price can vary based on factors like abrasive type, bond quality, and brand reputation. While cheaper alternatives might be tempting, professional operators know that a higher initial cost often means improved lifespan and fewer operational issues. A premium cutting wheel not only reduces downtime but also enhances safety by minimizing the risk of wheel breakage during high-speed cutting.

Specialized Use of Carbon Steel Cutting Disc for Tough Materials

Certain cutting tasks demand discs designed specifically for tougher metals like carbon steel. The carbon steel cutting disc is manufactured to provide optimal cutting speed and edge retention when working with this material. Carbon steel, known for its hardness and durability, requires a disc that can withstand high friction and heat buildup. This cutting disc uses specialized abrasive compounds and reinforced backing to ensure a clean, precise cut every time, making it indispensable in heavy fabrication shops and metal workshops.

Carbon Cutting Disc: High Efficiency Meets Extended Durability

For users seeking an all-around performer, the carbon cutting disc offers a great combination of cost-effectiveness and endurance. These discs are designed to slice through carbon-rich metals with minimal blade wear, thanks to their advanced composite materials. Additionally, the carbon cutting disc excels in applications requiring repetitive, high-speed cuts, delivering both efficiency and safety. Its ability to maintain cutting accuracy while dissipating heat effectively contributes to longer service life, a crucial advantage in fast-paced industrial environments.

Why Choose a 5 in Cut Off Wheel Over Larger Sizes?

The compact size of a 5-inch cut off wheel offers excellent control and accessibility, especially in tight or confined spaces. Unlike larger wheels, it allows for more precise cuts and is lighter, reducing user fatigue during extended use.

What Factors Affect the 5 Inch Cutting Wheel Price?

Several elements influence pricing, including the abrasive type (aluminum oxide, silicon carbide, etc.), bonding resin quality, manufacturing process, and additional features like reinforced fiberglass backing for added safety.

How Does the Carbon Steel Cutting Disc Enhance Cutting Efficiency?

These discs are optimized to cut through dense, tough metals without chipping or excessive heat buildup, which helps maintain blade sharpness and reduce operator downtime.

Cutting Disc Solutions FAQs

Q: What is the typical lifespan of a 5 in cut off wheel during daily use?

A: Lifespan varies with usage intensity, but premium wheels can last for dozens of precise cuts before needing replacement, depending on material hardness and cutting frequency.

Q: Can the cutting disc 5 inch be used for both metal and masonry materials?

A: Yes, but it's important to select the appropriate disc type designed specifically for each material to ensure safety and effectiveness.

Q: How significant is the price difference between carbon cutting discs and standard cutting discs?

A: Carbon cutting discs tend to be slightly more expensive due to their enhanced materials and construction, but the durability and cutting quality they provide justify the investment.

Q: Are 5 inch cutting wheel price variations due to brand or manufacturing quality?

A: Both factors play a role; reputable brands often use better raw materials and quality control processes, leading to more reliable and safer products.

Q: What safety precautions should I take when using carbon steel cutting discs?

A: Always wear appropriate protective gear, ensure the disc is properly mounted, and avoid excessive pressure during cutting to prevent disc damage or accidents.

Post time:Aug - 20 - 2025