Precision cutting is critical in both industrial fabrication and personal DIY projects. Choosing the right tool not only affects the efficiency of your operations but also the safety, finish quality, and durability of the workpiece. For aluminium, a soft yet versatile material, using the correct cutting tool is vital to achieving a clean edge and preventing material deformation. Among the top-tier choices for cutting non-ferrous metals are aluminum-specific cutting discs and wheels designed to work with angle grinders and other rotary tools.

Many Fabricators Choose the Best Aluminium Cut Off Disc for Cleaner Finishes

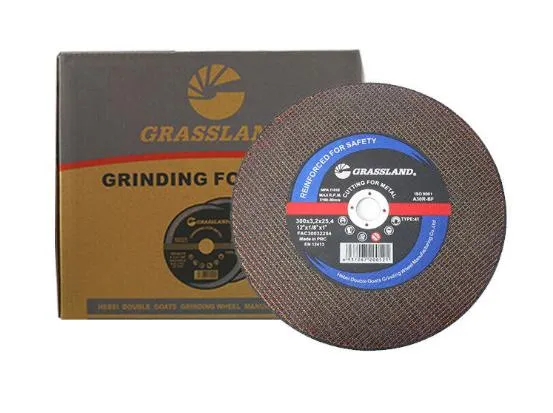

In metal workshops and manufacturing environments, a high-quality aluminium cut off disc can dramatically improve cutting performance. These discs are engineered specifically for soft metals, avoiding the clogging and friction issues commonly associated with standard abrasive tools. Unlike generic cutting discs that may leave burrs or warp thinner aluminum sheets, aluminum-specific discs are bonded with materials that produce lower heat and allow for smoother operation. This results in better edge integrity and less need for post-processing.

Efficiency Increases with Proper Use of an Aluminium Cut Off Wheel on Rotary Grinders

Achieving maximum efficiency on the job often depends on tool pairing. When using an angle grinder, the aluminium cut off wheel must be chosen carefully for both size and abrasive composition. These wheels are often reinforced with fiberglass to maintain structural integrity under high RPMs and offer a safer experience. Not only do they allow for swift cuts through aluminum sheets and bars, but their optimized grain structure also minimizes wear on the wheel, saving costs over time and reducing tool replacement frequency.

The Aluminium Cutting Disc for Angle Grinder Remains an Industry Staple

Metalworking professionals frequently rely on the aluminium cutting disc for angle grinder because it delivers consistent performance on a wide range of aluminum profiles, pipes, and plates. Its compatibility with popular grinder models ensures flexibility, while its thin profile allows for precision cutting with minimal material loss. Compared to thicker cutting tools, these specialized discs reduce the amount of pressure required from the user, helping avoid user fatigue while maintaining clean, accurate results. For projects requiring intricate cuts, this type of disc is an essential component.

Improve Workflow by Selecting the Right Aluminium Cutting Disk for the Job

A single aluminium cutting disk can significantly impact your workflow. Using a tool that's not optimized for aluminum can slow down productivity and lead to equipment wear or part failure. A cutting disk designed for aluminum helps avoid overheating and material buildup, which are common issues when using multipurpose blades. Moreover, aluminum-specific disks typically come with labeling and safety ratings that help operators select the ideal tool for their equipment and task, ensuring optimal alignment between material, machine, and result.

Industrial Workshops Benefit Long-Term from Quality Aluminium Cutting Wheel Choices

Durability and precision are the two most sought-after attributes in any cutting tool. A well-crafted aluminium cutting wheel provides a longer service life and consistent output under high workloads. These wheels are particularly advantageous in automotive, aerospace, and architectural industries where aluminum components are widely used. Investing in high-performance cutting wheels also reduces downtime, as fewer replacements and adjustments are needed throughout the workflow. Their ability to retain cutting efficiency even after repeated use makes them a trusted tool in heavy-duty settings.

Factors That Influence the Lifespan of Aluminium Cutting Discs and Wheels

The lifespan of a cutting disc is determined by several factors including the abrasive material, bond hardness, operating speed, and the pressure applied during use. Choosing a disc that is specifically designed for aluminum reduces friction and wear, extending its usability and ensuring better cut results.

Choosing Between Thin and Thick Discs for Different Aluminium Applications

Thinner discs are ideal for precise and delicate cutting tasks, while thicker wheels may be suited for deeper cuts or bulk material removal. It's essential to match the disc's thickness with the project's requirement for optimal control and performance.

Aluminium Cutting Disc and Wheel FAQs

Q: What makes an aluminium cut off disc different from standard metal discs?

A: Aluminium cut off discs are made with specialized abrasives and bonding agents that prevent clogging and reduce heat generation, which is critical for cleanly cutting soft metals like aluminum.

Q: How can I use an aluminium cut off wheel safely with an angle grinder?

A: Always ensure the wheel is rated for the grinder's RPM. Use proper PPE, and avoid applying excessive pressure to prevent overheating and ensure the longevity of both the tool and disc.

Q: Why is an aluminium cutting disc for angle grinder better than a multipurpose one?

A: It’s engineered specifically for soft metal, minimizing burrs and offering faster, cleaner cuts with less effort compared to universal or steel-only discs.

Q: What size aluminium cutting disk should I use for home projects?

A: For small DIY tasks, a 115mm or 125mm disc is usually sufficient. These sizes offer good maneuverability and precision, particularly for handheld grinders.

Q: How long does an aluminium cutting wheel last in regular use?

A: With proper usage and storage, a high-quality cutting wheel can last through dozens of cuts. However, its lifespan will vary depending on material thickness and cutting frequency.

Post time:Aug - 20 - 2025