In the world of construction and masonry, achieving clean, accurate cuts through bricks, blocks, and stone requires more than just force—it demands the right tools. The angle grinder has become a go-to piece of equipment for both professionals and skilled DIYers, known for its versatility and speed. However, what truly determines the success of any brick-cutting task lies in the quality and compatibility of the cutting disc attached. Not all discs are made equal, especially when dealing with dense, abrasive materials like bricks or concrete blocks. Choosing the right masonry disc isn't simply about cutting—it’s about efficiency, safety, and the durability of both your equipment and your workmanship.

Maximum Efficiency Begins with the Right Angle Grinder Brick Cutting Disc

When precision and speed matter most, using an angle grinder brick cutting disc optimized for masonry is essential. These discs are designed to tackle the density and abrasiveness of brick without losing cutting power or degrading quickly. Standard metal or general-purpose discs can wear out rapidly or crack when used on bricks, which not only shortens their lifespan but also introduces safety risks. Brick-specific grinder discs, often embedded with industrial-grade specialized abrasives, ensure deep penetration and a consistent finish with minimal chipping. This significantly reduces the need for post-cut smoothing or adjustments, streamlining your workflow on-site.

Worksite Productivity Improves with an Angle Grinder Disc for Cutting Bricks

Contractors know that time is money. When equipped with the right angle grinder disc for cutting bricks, workers can move seamlessly from cut to cut without delays due to overheating, dull edges, or poor performance. These discs are usually engineered with segment slots or turbo edges that dissipate heat efficiently and minimize friction, allowing for longer cutting sessions without damage to the grinder or material. Whether you’re slicing through standard clay bricks or handling denser concrete blocks, a purpose-built disc ensures your work meets both speed and precision standards.

Choose the Best Angle Grinder Discs for Masonry Durability

General-purpose grinder wheels may suffice for soft metals or wood, but they can’t match the toughness required for masonry. The angle grinder discs for masonry on the market today incorporate advanced bonding agents and reinforced cores to maintain structural integrity even under extreme cutting pressures. The result is a disc that resists deformation, cracking, and excessive dust generation, which is not only better for user health but also keeps your worksite cleaner. A cleaner cut also means reduced wear on your grinder’s motor and less frequent need for blade replacement.

Safety and Speed Coexist in Angle Grinder Discs Masonry Performance

Using angle grinder discs masonry applications demand can mean dealing with hard, brittle surfaces that can fracture or splinter under poor cutting conditions. High-performance masonry discs are tested for rotational stability at high RPMs and often come with certifications for industrial safety compliance. This ensures that even under the stress of continuous use, the disc remains predictable and safe. In high-volume cutting tasks—like fitting dozens of bricks to size in a single session—this reliability isn’t just helpful, it’s critical. A disc that performs consistently across multiple types of brick, from standard clay to hollow and high-density cement units, maximizes worker confidence and task accuracy.

Enhance Every Cut Using the Right Angle Grinder Masonry Cutting Disc

Bricks may vary, but the need for accuracy remains universal. The angle grinder masonry cutting disc offers sharpness retention, low vibration, and edge resilience—characteristics that define professional-level tools. These discs typically feature segmented or continuous rims for handling both straight and curved cuts, essential in applications like archways or complex masonry layouts. Beyond the blade itself, many discs are now optimized for both wet and dry cutting, giving the user flexibility depending on the environment and job type. With consistent edge strength and performance, a quality masonry cutting disc is not just a consumable—it’s a cornerstone of professional toolkits.

What to Consider When Selecting Masonry Discs

While all masonry discs aim to cut through tough surfaces, only some offer the features needed for demanding professional use. When selecting a disc, assess the following:

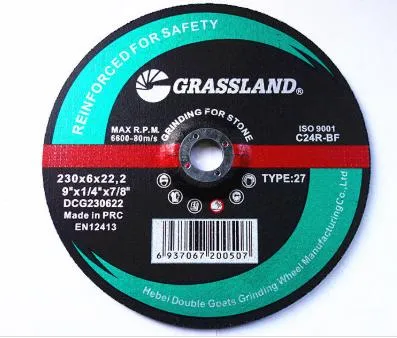

Material composition: Look for silicon carbide

Compatibility: Match the disc diameter and arbor hole with your grinder

Certifications: Ensure discs meet industry safety standards (e.g., EN12413)

Extending the Life of Your Grinder and Disc

Proper use, storage, and maintenance can dramatically extend the lifespan of both your angle grinder and its cutting disc. Avoid forcing the blade through material—let the disc do the work. Store discs flat in dry environments, and clean the grinder regularly to prevent dust buildup and overheating. These small practices translate into fewer tool replacements, less downtime, and greater project profitability.

Angle Grinder Masonry Cutting Disc FAQs

Q: Can I use a metal-cutting disc instead of an angle grinder brick cutting disc?

A: No. Metal discs are not designed for the density and abrasion of masonry and can fail quickly or even shatter. Always use masonry-specific discs.

Q: How often should I replace an angle grinder masonry cutting disc?

A: Replace it when cutting efficiency drops, edges wear down unevenly, or you notice increased vibration or sparks. Regular inspection is key to safety.

Q: Can angle grinder discs for cutting bricks be used on concrete or stone?

A: Yes, most masonry discs can handle concrete and natural stone, but check manufacturer specs to ensure proper compatibility.

Q: Do angle grinder discs masonry tools generate harmful dust?

A: Yes. Always use proper ventilation and wear safety gear like masks and goggles,

Post time:Aug - 20 - 2025