When it comes to cutting through tough materials like brick, stone, concrete blocks, and tile, having the right tool is critical—not just for speed, but for accuracy, consistency, and safety. In professional construction, renovation, and DIY projects alike, masonry cutting wheels provide the reliability needed for high-stress applications. Modern advancements in abrasive technology have improved their durability, cutting speed, and performance across different wheel sizes and formats.

High-Speed Workflows Depend on the Efficiency of a 4 1 2 Inch Masonry Cutting Wheel

On many job sites, the 4 1 2 inch masonry cutting wheel has become the preferred choice for compact angle grinders. Despite its small size, it delivers excellent speed and control, making it ideal for fine cuts and detail work. Operators benefit from its lightweight profile and ability to operate in confined or awkward spaces without compromising stability. Whether you're cutting grooves in patio blocks or trimming bricks to size, this wheel delivers results without fatigue.

Safety and Strength Combine in Every 4 1 2 Masonry Cut Off Wheel Session

Contractors trust the 4 1 2 masonry cut off wheel for its strong build and resistance to edge wear. Unlike standard blades that may chip or wear unevenly, these cut off wheels provide uniform material removal and minimize heat buildup during use. The bonded abrasive layers maintain their structure even under high torque, reducing the chance of breakage or dangerous kickback—making them essential for projects requiring constant speed and smooth finishes.

The Power Behind a 125mm Masonry Cutting Disc Lies in Its Versatility

Across both commercial and residential sectors, the 125mm masonry cutting disc supports a wide variety of applications. Its slightly larger size compared to 4.5-inch wheels provides added cutting depth and better edge life, especially when used in tandem with mid-sized angle grinders. This disc size is often the best choice for cutting through thicker masonry like paving stones or larger cinder blocks where precision and depth both matter. Despite the increased cutting area, the disc remains easy to control with minimal vibration.

Large-Scale Jobs Demand the Performance of a 7 Masonry Cut Off Wheel

For industrial applications, the 7 masonry cut off wheel dominates in both strength and cutting capacity. When mounted on a 7-inch angle grinder or a circular saw, this wheel can slice through concrete beams, heavy pavers, or stone veneer with ease. Its thicker composition allows for extended use without the risk of premature wear or warping. Professionals choose this size for demolition jobs or structural modifications, where time, speed, and tool life are crucial.

Smooth Cutting Begins with a Reliable 4.5 Inch Masonry Cutting Wheel on Site

The 4.5 inch masonry cutting wheel is widely favored in both indoor and outdoor construction settings for its manageable size and stable operation. With just the right balance between cutting depth and maneuverability, it works exceptionally well for detail-oriented tasks, like shaping stone tiles or trimming thin concrete slabs. The grain structure and bonding agent of these wheels have been fine-tuned over the years, making them more efficient at cutting while reducing dust and friction.

Choosing the Right Wheel Diameter for Different Cutting Needs

Wheel size matters. Smaller wheels such as the 4.5-inch and 125mm are best suited for tight workspaces, edge trimming, and shaping. Larger sizes, like the 7-inch wheel, are ideal for full-depth cuts and heavy-duty workloads. It's important to match the wheel not only to the tool but also to the task at hand—especially when precision and safety are top priorities.

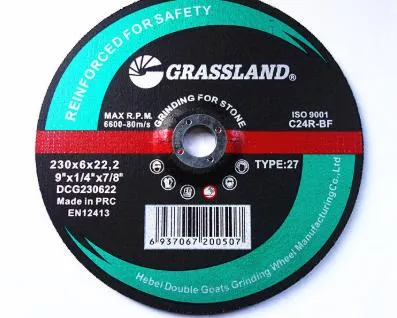

Abrasive Composition and Bonding Affect Cutting Quality and Speed

The material that forms the cutting surface of masonry wheels—typically aluminum oxide or silicon carbide—greatly impacts performance. Better bonding resins and improved grain orientation mean a faster, cleaner cut. Manufacturers now incorporate heat-resistant technologies that help these wheels maintain shape and structure under intense workloads.

Avoiding Common Errors When Using Masonry Cutting Wheels

Improper use or pairing of cutting wheels with the wrong tool type can lead to dangerous outcomes. Avoid using a wheel size that’s incompatible with your angle grinder, and never exceed recommended RPM limits. Always use proper eye protection, gloves, and dust masks to protect against fine particulate matter during cutting sessions.

4 1 2 Inch Masonry Cutting Wheel and Related Products FAQs

Q: What is the difference between a 4 1 2 inch masonry cutting wheel and a cut off wheel of the same size?

A: While they appear similar, a 4 1 2 inch masonry cutting wheel is often optimized for smoother cuts and minimal dust, whereas a 4 1 2 masonry cut off wheel is designed for straight, fast cuts and more aggressive material removal.

Q: Can I use a 125mm masonry cutting disc on a 5-inch angle grinder?

A: Yes, as long as the spindle size matches and the disc is rated for the grinder’s RPM. A 125mm masonry cutting disc offers a deeper cut and is commonly used in European markets.

Q: Why would I choose a 7 masonry cut off wheel over smaller options?

A: The 7 masonry cut off wheel provides deeper and wider cuts in fewer passes, making it more efficient for large-scale demolition or foundation work.

Q: How long does a 4.5 inch masonry cutting wheel typically last?

A: Lifespan depends on usage, material hardness, and operator technique. On average, a 4.5 inch masonry cutting wheel can last through several dozen cuts if used properly and cooled between sessions.

Q: What safety tips should I follow when using masonry wheels?

A: Always inspect the wheel for cracks before use, mount it securely, and operate at the correct RPM. Use eye protection, gloves, and hearing protection, and avoid forcing the wheel through the material.

Post time:Aug - 20 - 2025